Rotating body material distribution mold and method for preparing artificial stone checkered plate by using same

A rotating body and artificial stone technology, applied in the direction of molds, pressing rollers, etc., can solve the problems of artificial color filling, unstable texture, short service life, difficult operation, etc., achieve environmental protection, high degree of automation, and fast pattern making speed , pattern realistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

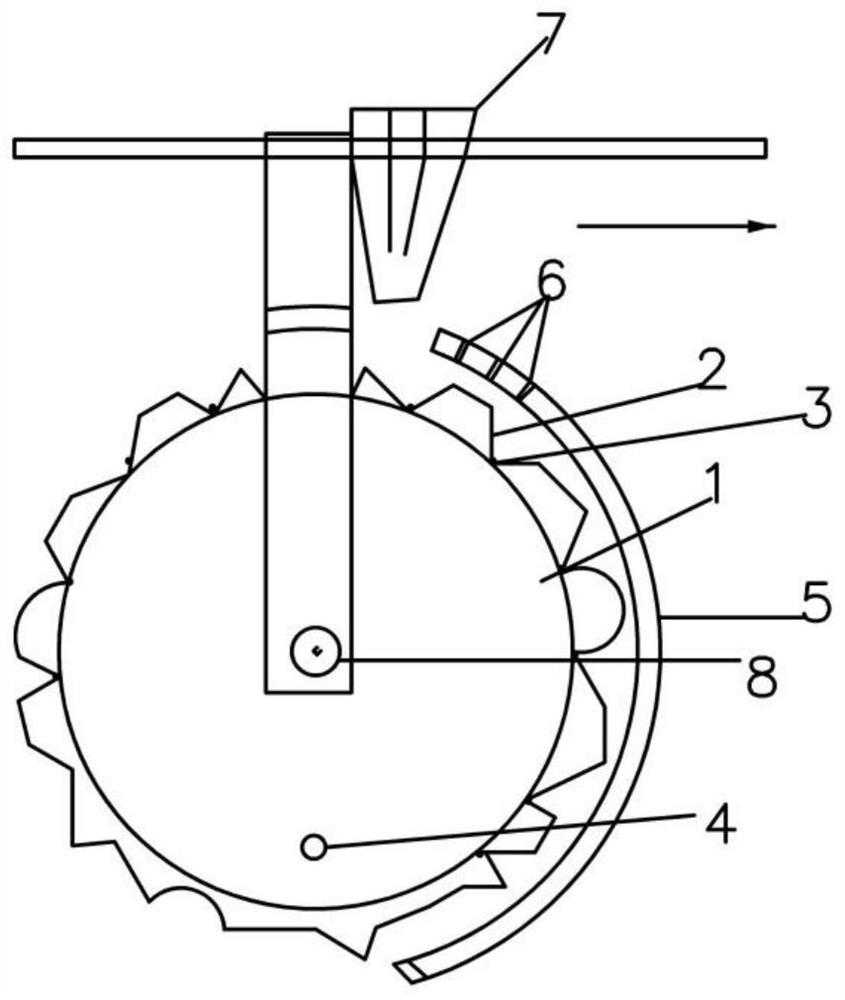

Embodiment 1

[0029] In this embodiment, an installation and manufacturing process of a concave-convex rotary cloth mold is proposed: firstly, a silicon rubber hollow cylinder 1 is made, with a diameter of 1050mm, a length of 1700mm, and a wall thickness of 50mm. A compressed air inlet 4 is set on one of the bottom surfaces of the silicone rubber hollow cylinder 1. According to the pre-designed pattern and layering requirements, the CNC engraving process CNC is used to carve the uneven texture groove 2 on the silicone rubber hollow cylinder 1. The depth of 2 includes four types: 10mm, 15mm, 20mm, and 30mm. Small air holes 3 communicating with the hollow cylinder 1 are distributed in the groove 2, and the diameter is 1mm. One of the bottom surfaces of the hollow cylinder 1 is provided with a compressed air inlet 4 , the side of the hollow cylinder 1 is provided with an arc-shaped material guide plate 5, and its thickness is 30mm; the material guide plate 5 is provided with a number of powder ...

Embodiment 2

[0031] In this example, a method for preparing artificial stone with fine grain and grain is proposed.

[0032] 1) Take raw materials by weight ratio:

[0033] Material A: 54% quartz sand, 30% quartz powder, 13% unsaturated polyester resin, 1.1% medium temperature curing agent, 1.0% coupling agent and 0.9% composite color paste A.

[0034] Material B: 55% quartz sand, 29% quartz powder, 12.8% unsaturated polyester resin, 1.2% medium temperature curing agent, 1.0% coupling agent and 1.0% composite color paste B.

[0035] Material C: 56% quartz sand, 29.5% quartz powder, 11.2% unsaturated polyester resin, 1.0% medium temperature curing agent, 0.8% coupling agent and 1.5% composite color paste C.

[0036] 2) Add the composite color paste corresponding to A, B, and C materials, unsaturated polyester resin, tert-butyl peroxy-2-ethylhexanoate, and γ-methacryloxypropyltrimethoxysilane Stir evenly in the resin mixing tank, then pour it into the mixer containing pre-mixed quartz sand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com