Patents

Literature

51results about How to "Enhanced 3D effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

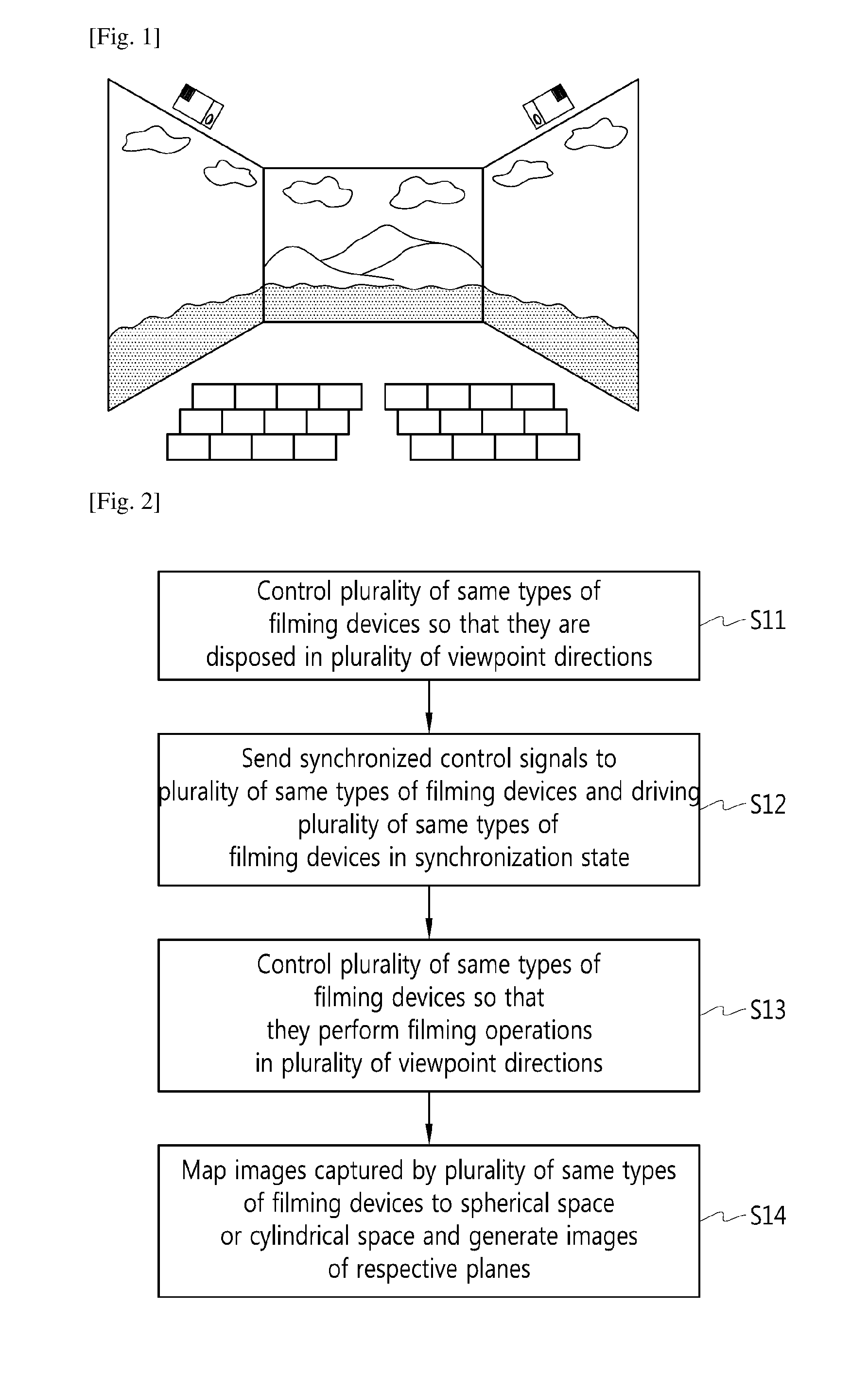

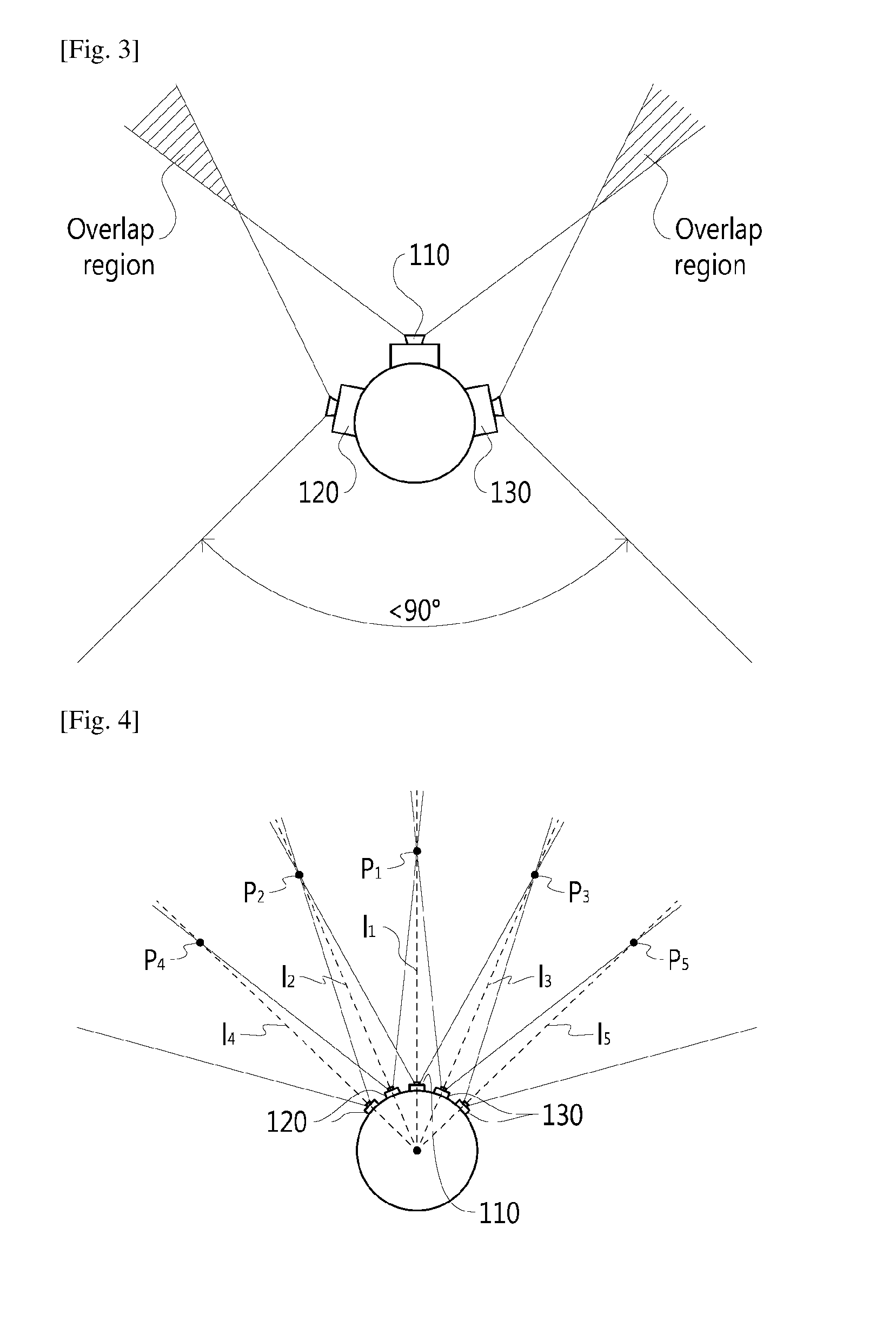

Method and system for generating multi-projection images

InactiveUS20160328824A1Enhanced 3D effectSimple structureImage enhancementTelevision system detailsProjection imageAngle of view

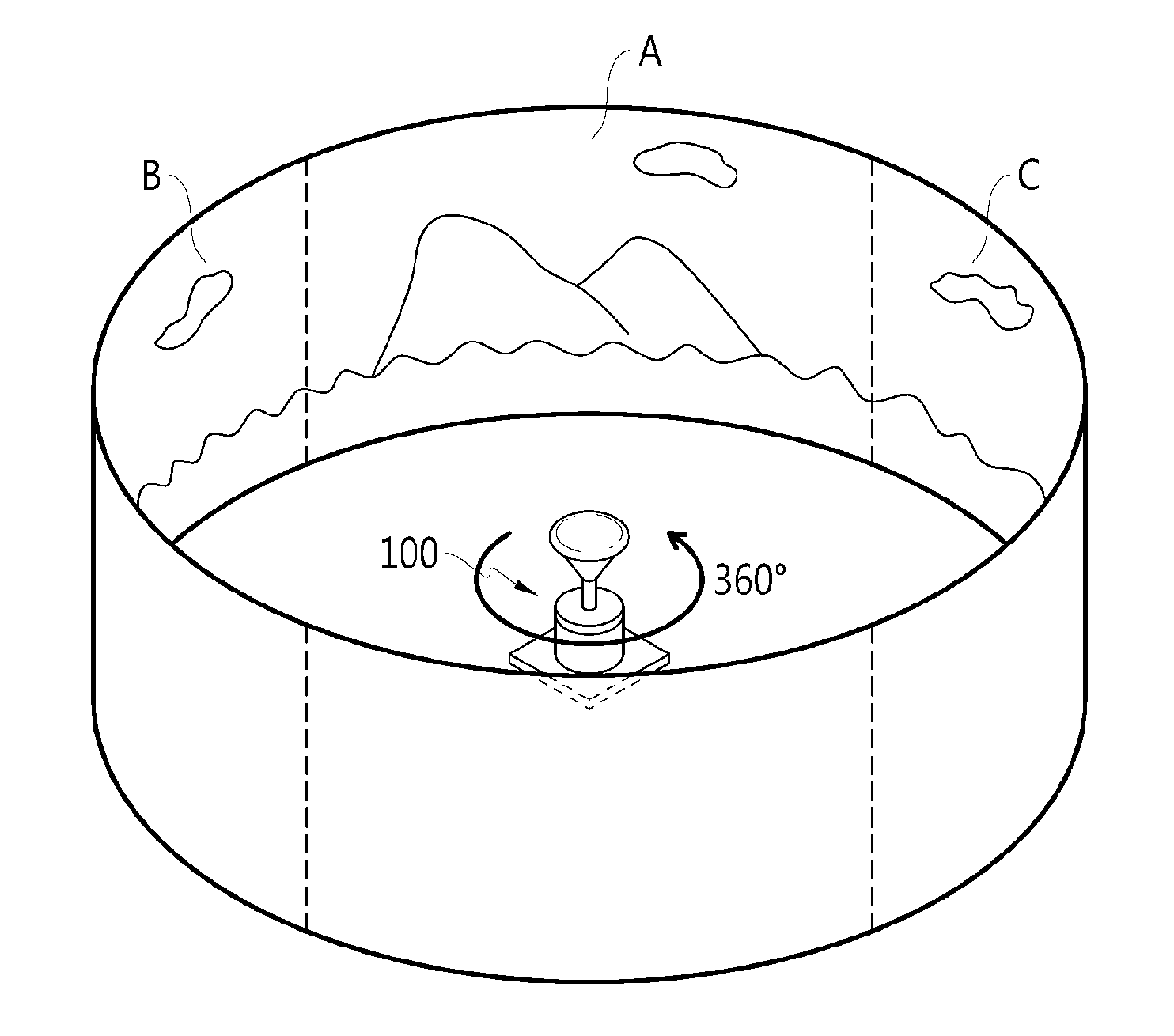

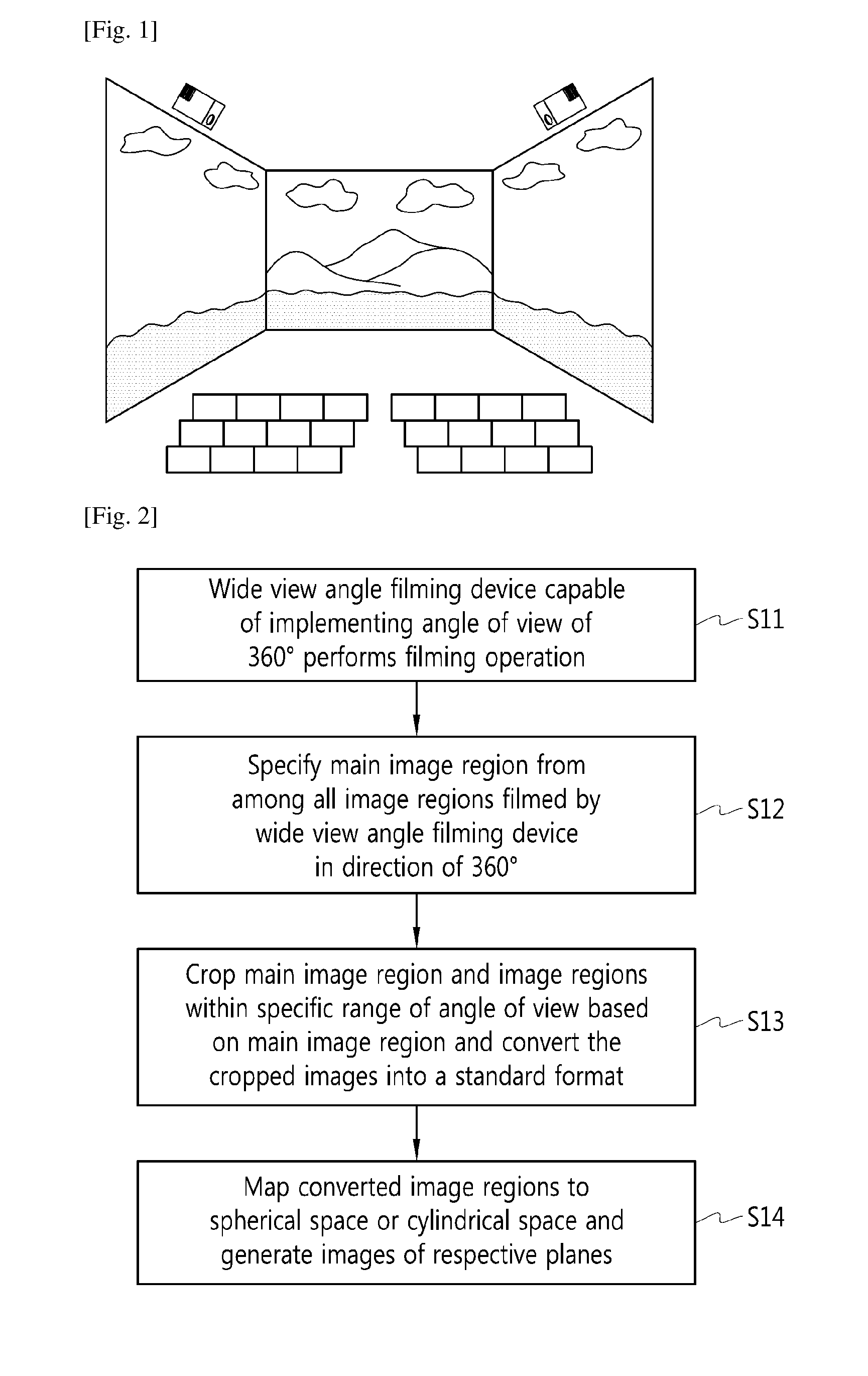

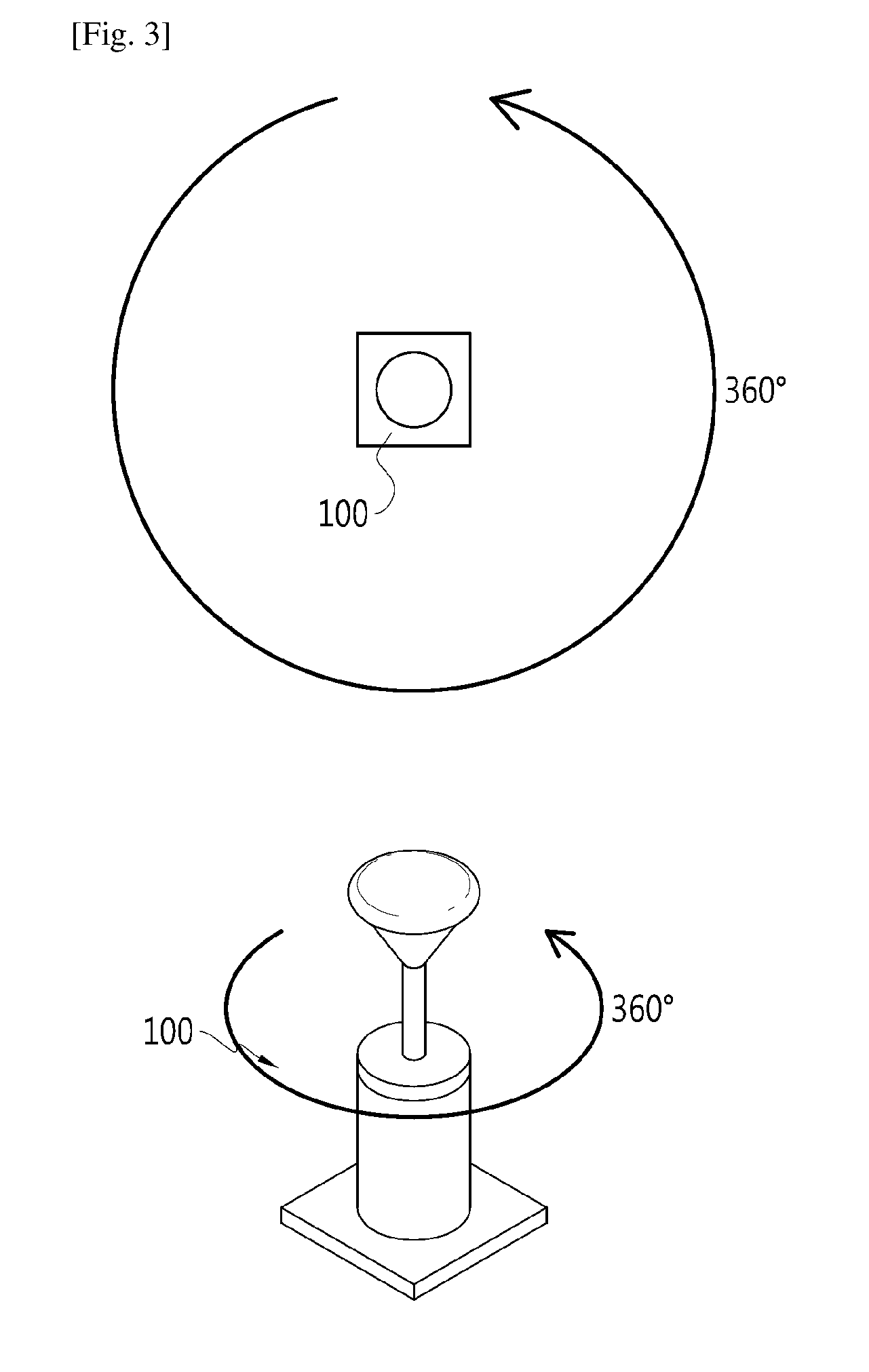

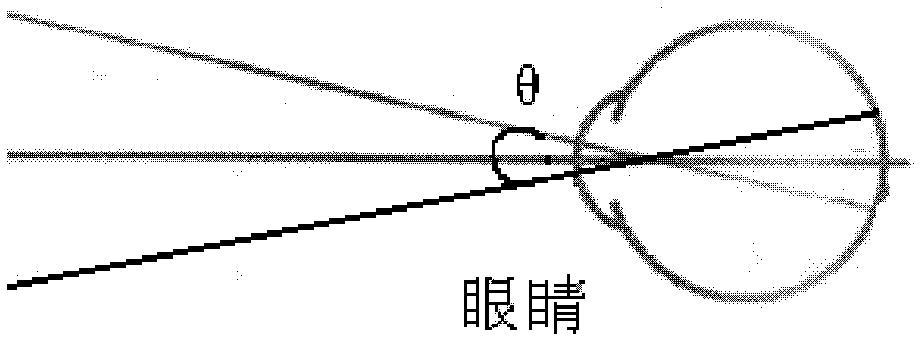

Disclosed herein is a method of generating multi-projection images. The method of generating multi-projection images includes performing, by a wide view angle filming device capable of implementing an angle of view of 360°, a filming operation and specifying a main image region from among all the image regions filmed by the wide view angle filming device in a direction of 360°.

Owner:CJ CGV

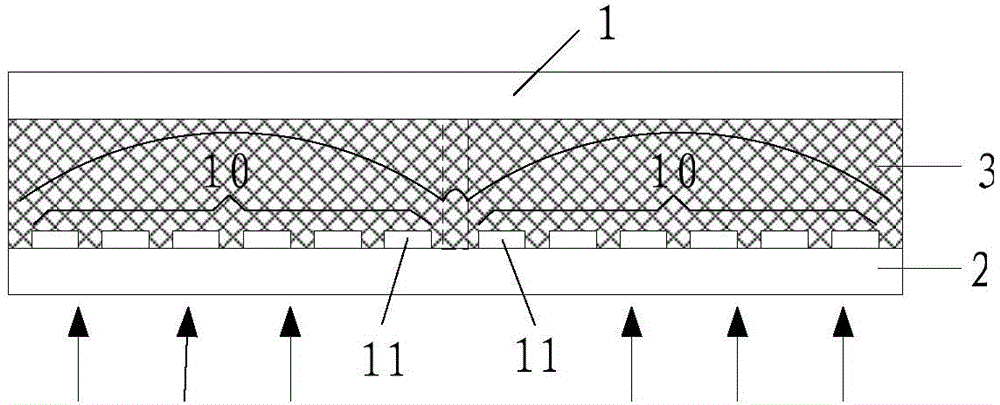

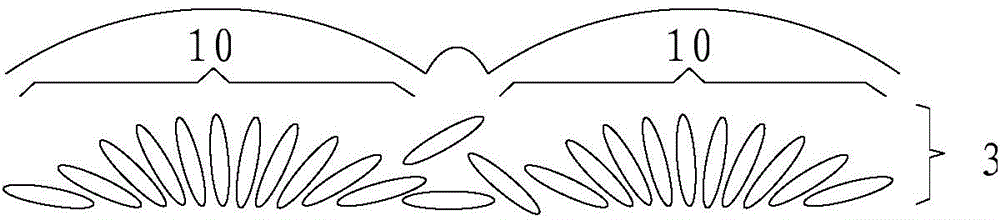

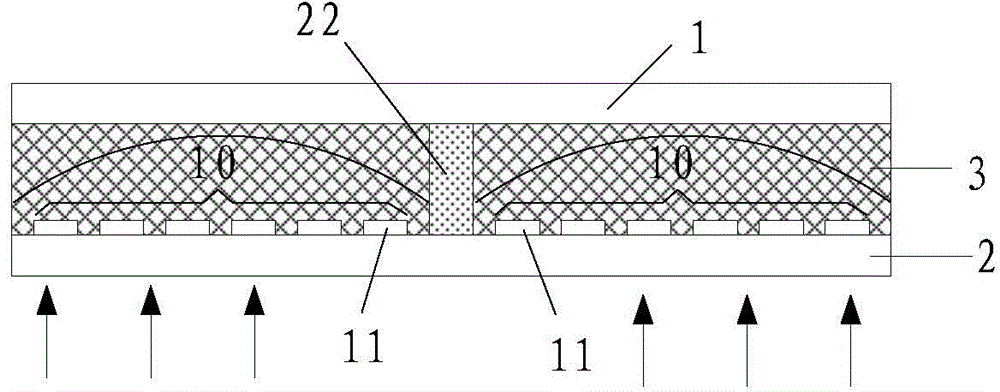

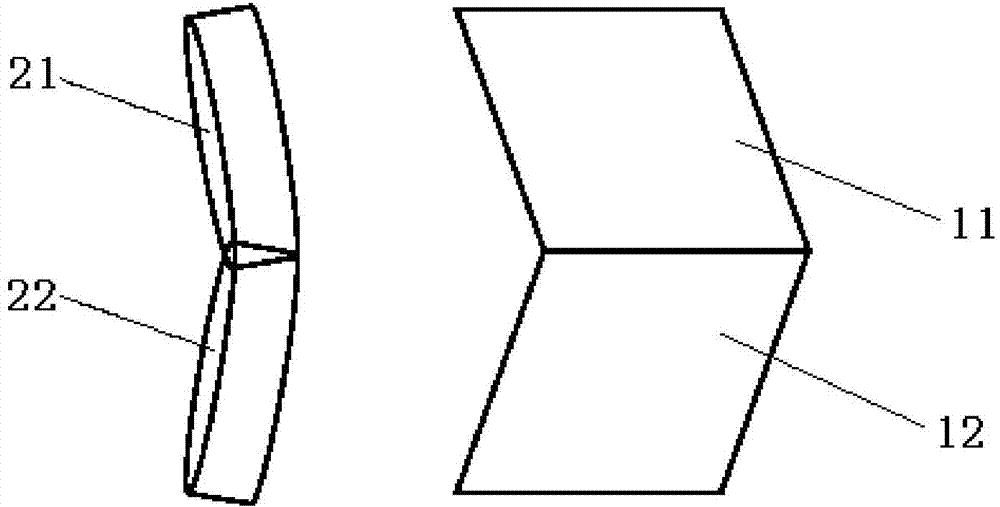

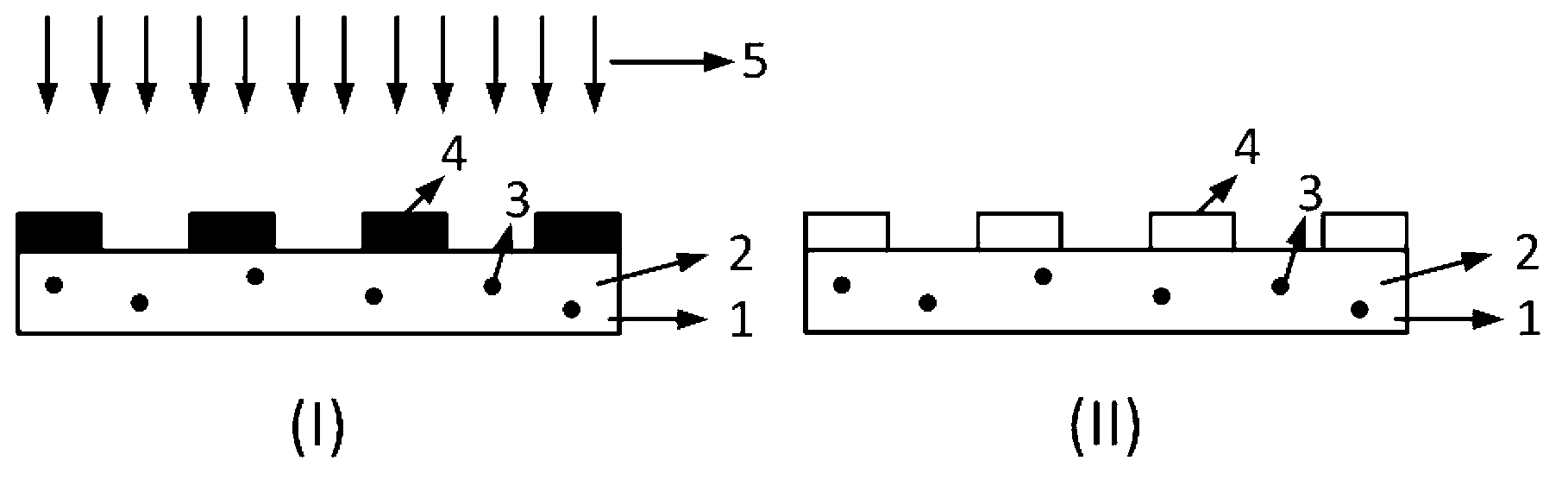

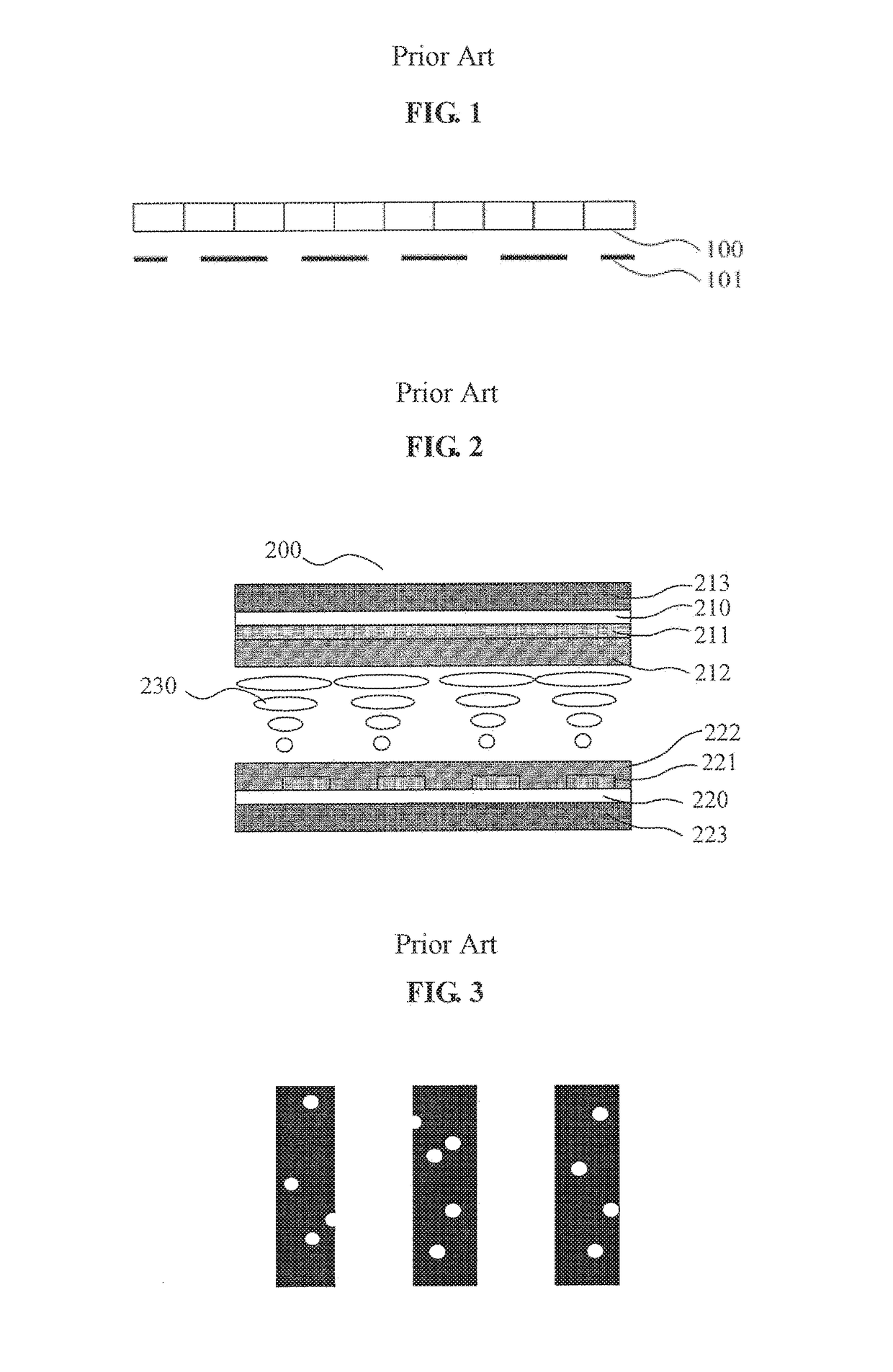

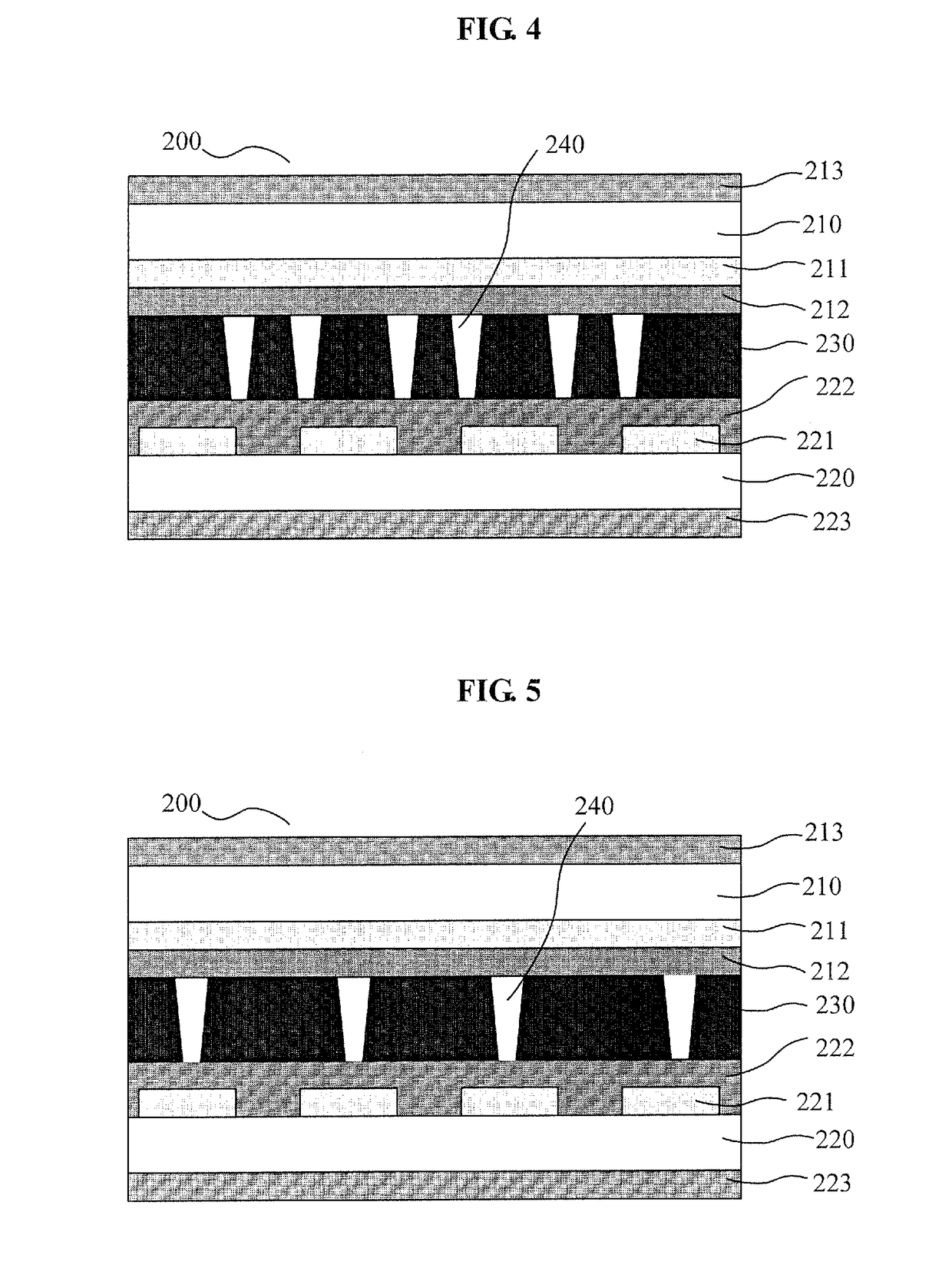

Liquid crystal prism, manufacturing method thereof and display device

ActiveCN103558724AEnhanced 3D effectNon-linear opticsOptical elementsLiquid-crystal displayDisplay device

The invention provides a liquid crystal prism, a manufacturing method thereof and a display device, relates to the field of a display technology, and solves the problems that light rays received by the left eye and the right eye are disordered and the 3D (3-dimensional) effect is influenced due to the fact that a conventional liquid crystal prism has liquid crystal disclination in an area between two adjacent strip-shaped electrode assemblies. The liquid crystal prism comprises an upper substrate, a lower substrate and a liquid crystal layer arranged between the upper substrate and the lower substrate, wherein a plurality of electrode assemblies are arranged on the upper substrate or the lower substrate; each electrode assembly comprises a plurality of mutually insulated electrodes; and a transparent spacer is arranged between every two adjacent electrode assemblies and enables liquid crystals on two sides to have a certain deflection angle.

Owner:BOE TECH GRP CO LTD

Optical displaying device for carrying out three-dimensional imaging on two-dimensional images

InactiveCN104714305AHigh resolutionRealize Stereoscopic ImagingOptical elementsEyepieceImage resolution

The invention relates to a display device, in particular to an optical displaying device for carrying out three-dimensional imaging on two-dimensional images. The optical displaying device comprises an image displaying system and an eyepiece system. The light emitting direction of the image displaying system faces the eyepiece system. The optical displaying device is characterized in that the image displaying system comprises two connected display screens which include the first display screen and the second display screen, the first display screen is located at the upper end of the second display screen, and the displaying face of the first display screen and the displaying face of the second display screen face the eyepiece system; the display screens are two-dimensional image display screens used for displaying the two-dimensional images; the eyepiece system comprises an eyepiece, and the portion where the first display screen is connected with the second display screen and the center of the eyepiece are located on the same plane; three-dimensional images formed by combining the displayed images of the first display screen and the displayed images of the second display screen are observed through the eyepiece system. According to the optical displaying device, light emitted by the first display screen and the second display screen is collected by the eyepiece system to be integrally converged into the eyes of an observer, and therefore the monocular resolution ratio can be quite high.

Owner:SHANGHAI NOVA OPTICS TECH

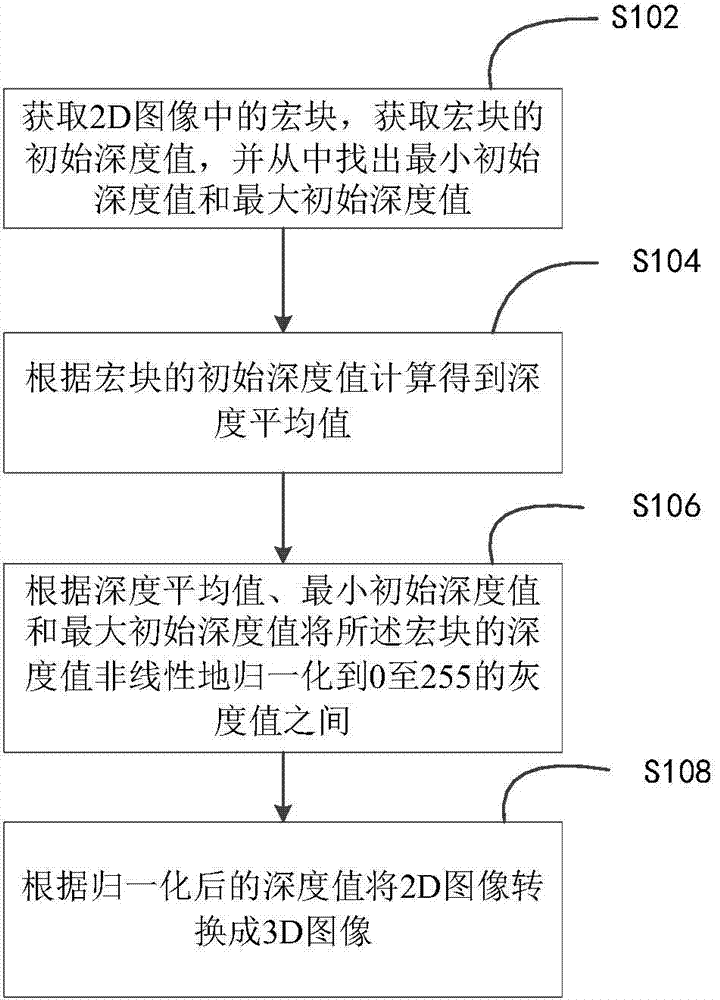

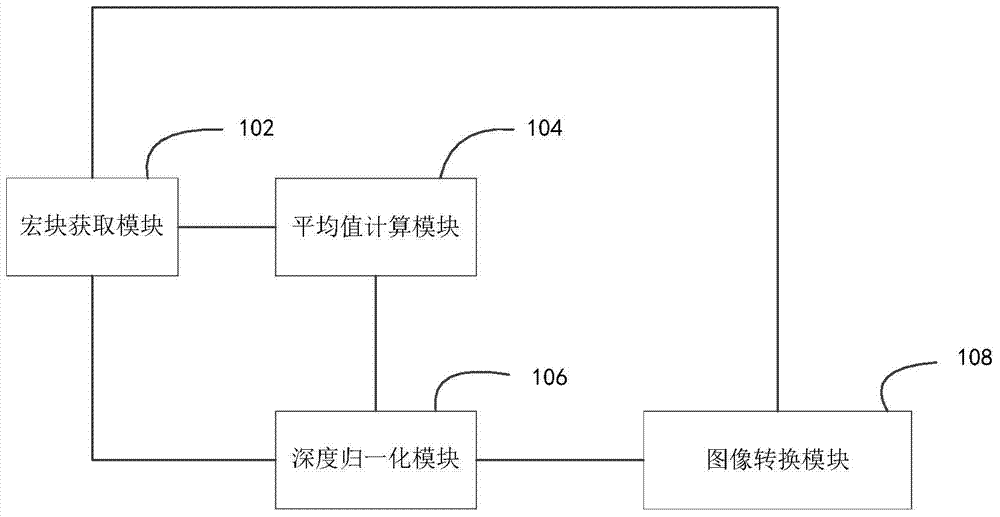

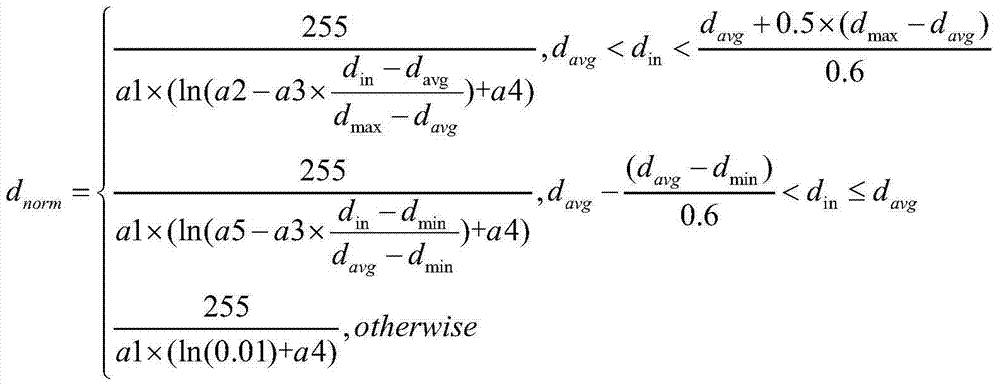

Depth adjusting method and device for converting 2D image to 3D image

InactiveCN104243948AReduce shakingEnhanced 3D effectSteroscopic systems3d imageComputer graphics (images)

The invention provides a depth adjusting method for converting a 2D image to a 3D image. The method includes the steps of obtaining macro blocks in the 2D image, obtaining initial depth values of the macro blocks, finding out the minimum initial depth value and the maximum initial depth value, obtaining an average depth value through calculation according to the initial depth values of the macro blocks, normalizing the depth values of the macro blocks to be the gray values ranging from 0 to 255 in a nonlinear mode according to the average depth value, the minimum initial depth value and the maximum initial depth value, and converting the 2D image to the 3D image according to the normalized depth value. The invention further provides a depth adjusting device for converting the 2D image to the 3D image. The depth adjusting method and device for converting the 2D image to the 3D image can improve the 3D effect.

Owner:深圳深讯和科技有限公司

Optically-controlled three-dimensional (3D) optical diaphragm and preparation method thereof

ActiveCN103076682AReduce ghostingImprove the display effectSynthetic resin layered productsDiffraction gratingsParallaxGrating

The invention discloses an optically-controlled three-dimensional (3D) optical diaphragm and a preparation method thereof. The optically-controlled 3D optical diaphragm is attached onto any display device capable of displaying a three-dimensional image, and image information with parallax of a left eye and a right eye can be split to the left eye and the right eye of a person to form naked-eye free three-dimensional display. The optically-controlled 3D optical diaphragm comprises a transparent diaphragm material layer and a photochromic grid bar, wherein the transparent diaphragm material layer is doped with zinc oxide nano particles 1,8-diiodooctane additive, the photochromic grid bar is transparent under the non-ultraviolet radiation to display two-dimensional information, the photochromic grid bar turns mazarine under the ultraviolet radiation to realize the grating effect and display the three-dimensional information, through the zinc oxide nano particles in the transparent diaphragm material layer, the transmission rate of the transparent diaphragm material layer is increased by utilizing an optical principle, the viewpoint width of the 3D display is increased, the double-image of the 3D display can be reduced, the 1,8-diiodooctane additive optimizes the dispersibility and uniformity of the zinc oxide nano particles, and the 3D display effect is finally enhanced.

Owner:JIANGYIN TONGLI OPTOELECTRONICS TECH

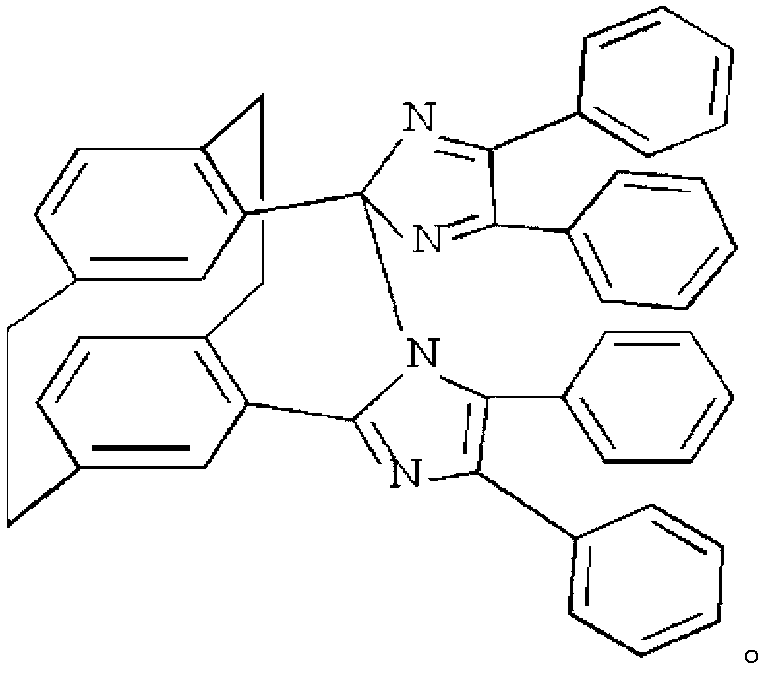

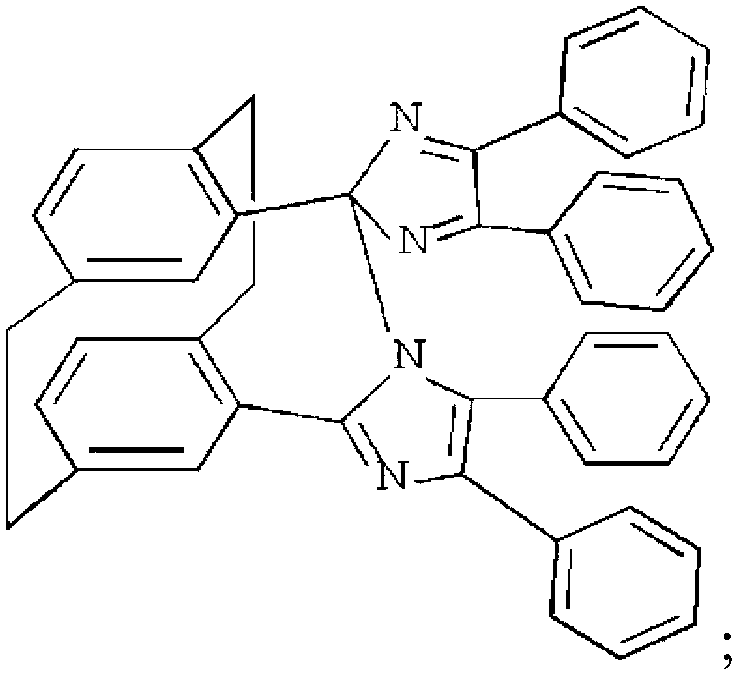

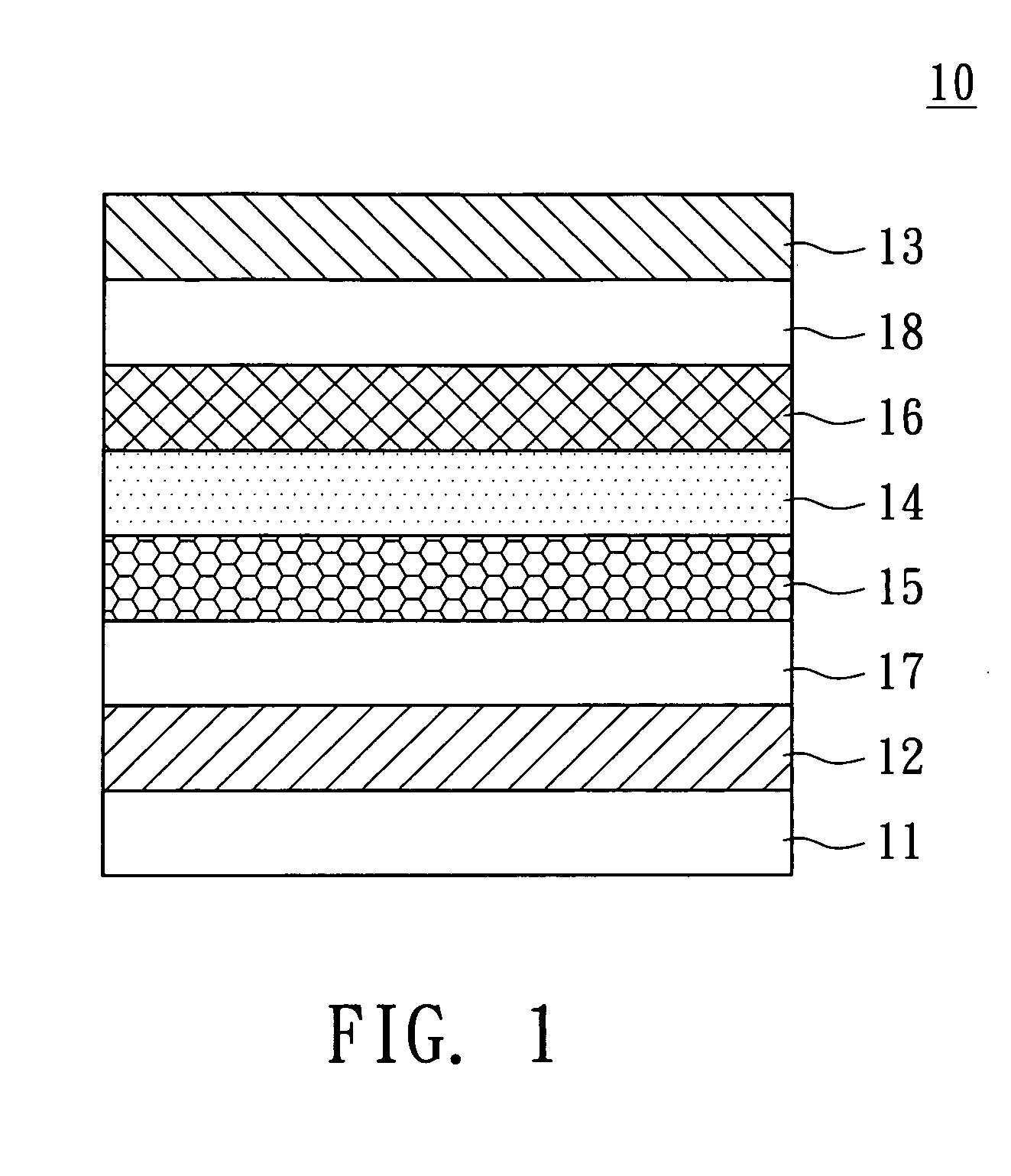

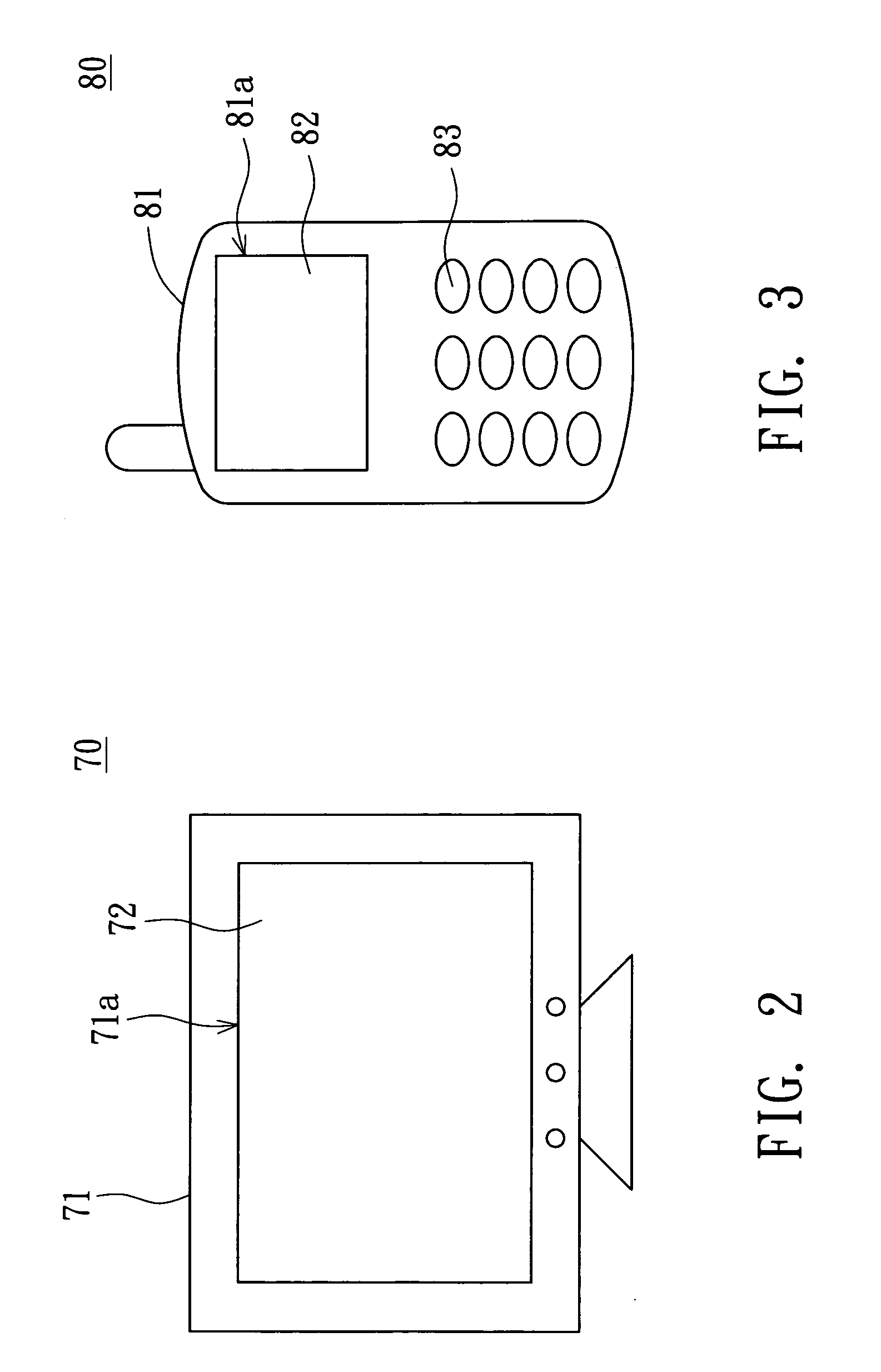

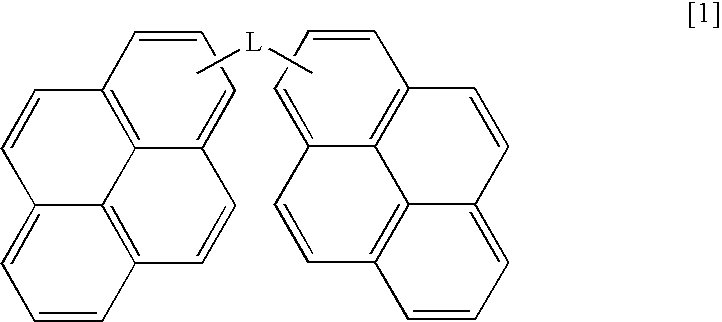

Light-emitting material and organic electroluminescent device using the same

ActiveUS20060240283A1Enhanced 3D effectReduce the effectOrganic chemistryDischarge tube luminescnet screensBenzeneChemical structure

An organic electroluminescent device (OELD) is provided. The OELD includes a substrate, an anode, a cathode and an emissive layer. The anode and the cathode opposite to the anode are disposed over the substrate. The emissive layer is disposed between the anode and the cathode. The emissive layer includes a light-emitting material. The chemical structure of the light-emitting material represented by the formula [1]: The chemically structure L is selected from a group consisting of the chemical structures AA, BB, AB, and the combination thereof. The chemical structure A of the formula [2]: The chemical structure X is selected from the group 4A to 6A elements of the periodic table. The chemical structure B is aromatic hydrocarbons having n benzene, n is a integer of 1 to 8. The chemical structure B of the formula [3]:

Owner:CHINA STAR OPTOELECTRONICS INT HK

3-dimensional scene imaging method and device and display terminal

InactiveCN102662292AAccurate 3D effectEnhanced 3D effectPrintersProjectorsComputer terminal3 d display

Owner:TCL CORPORATION

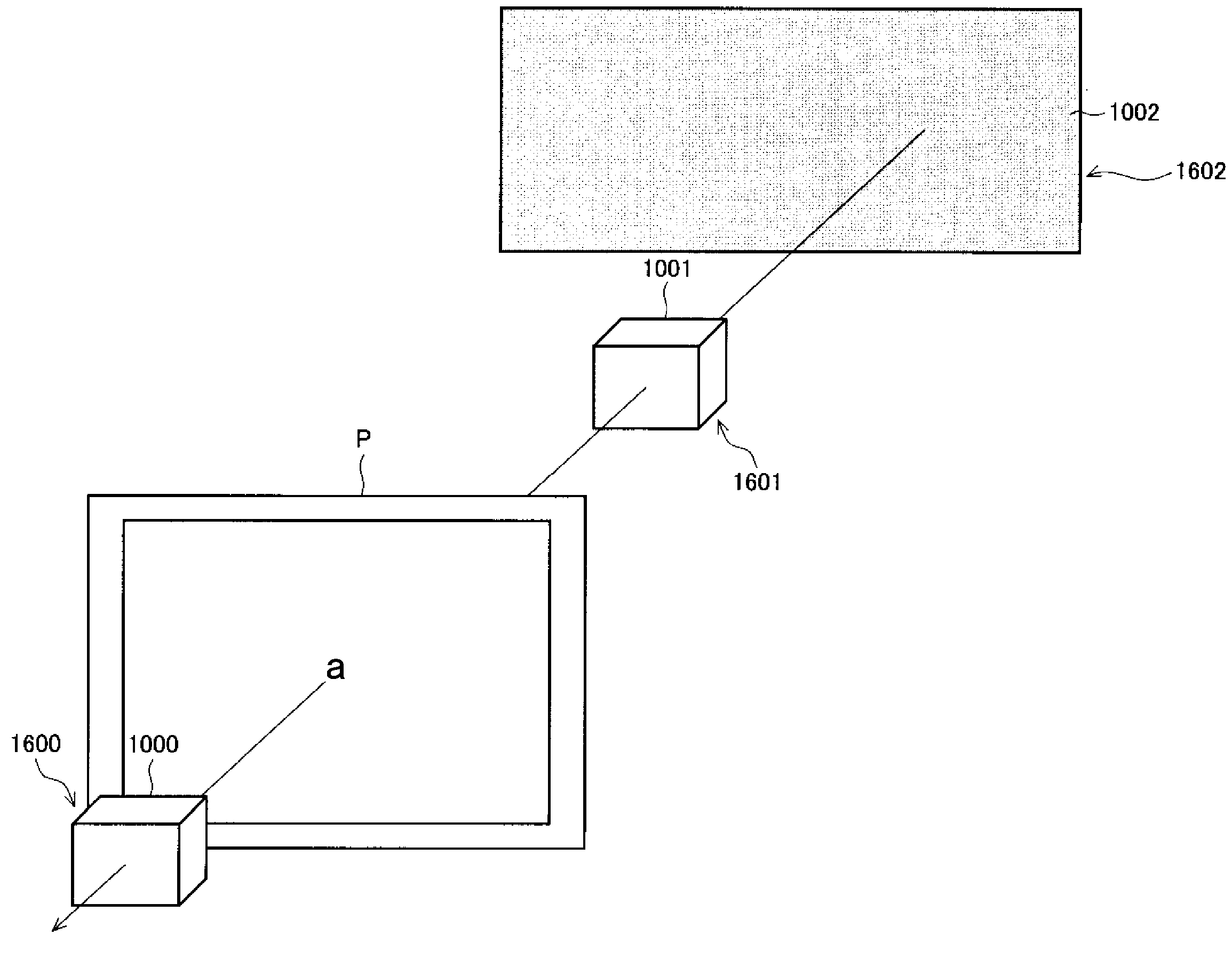

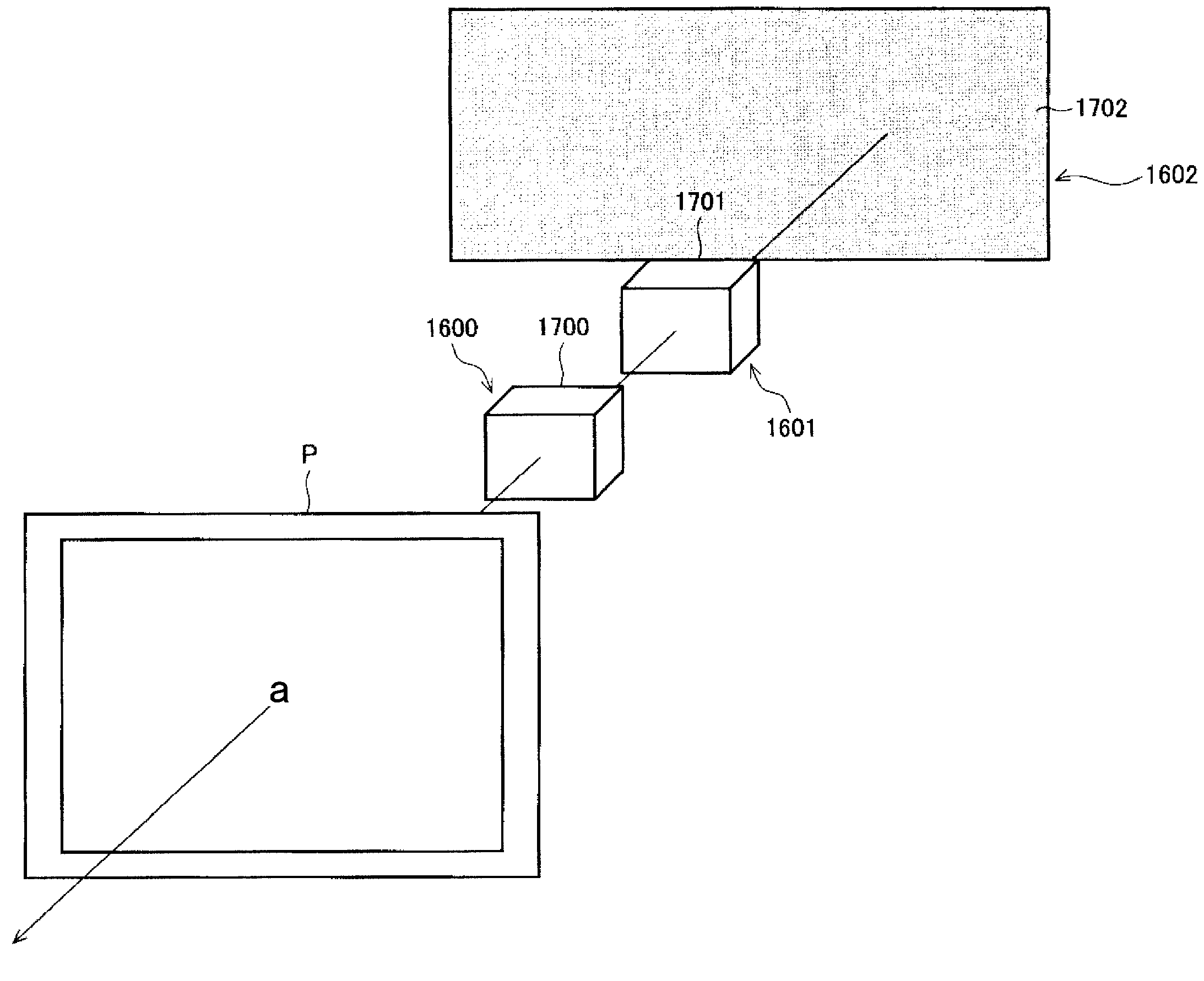

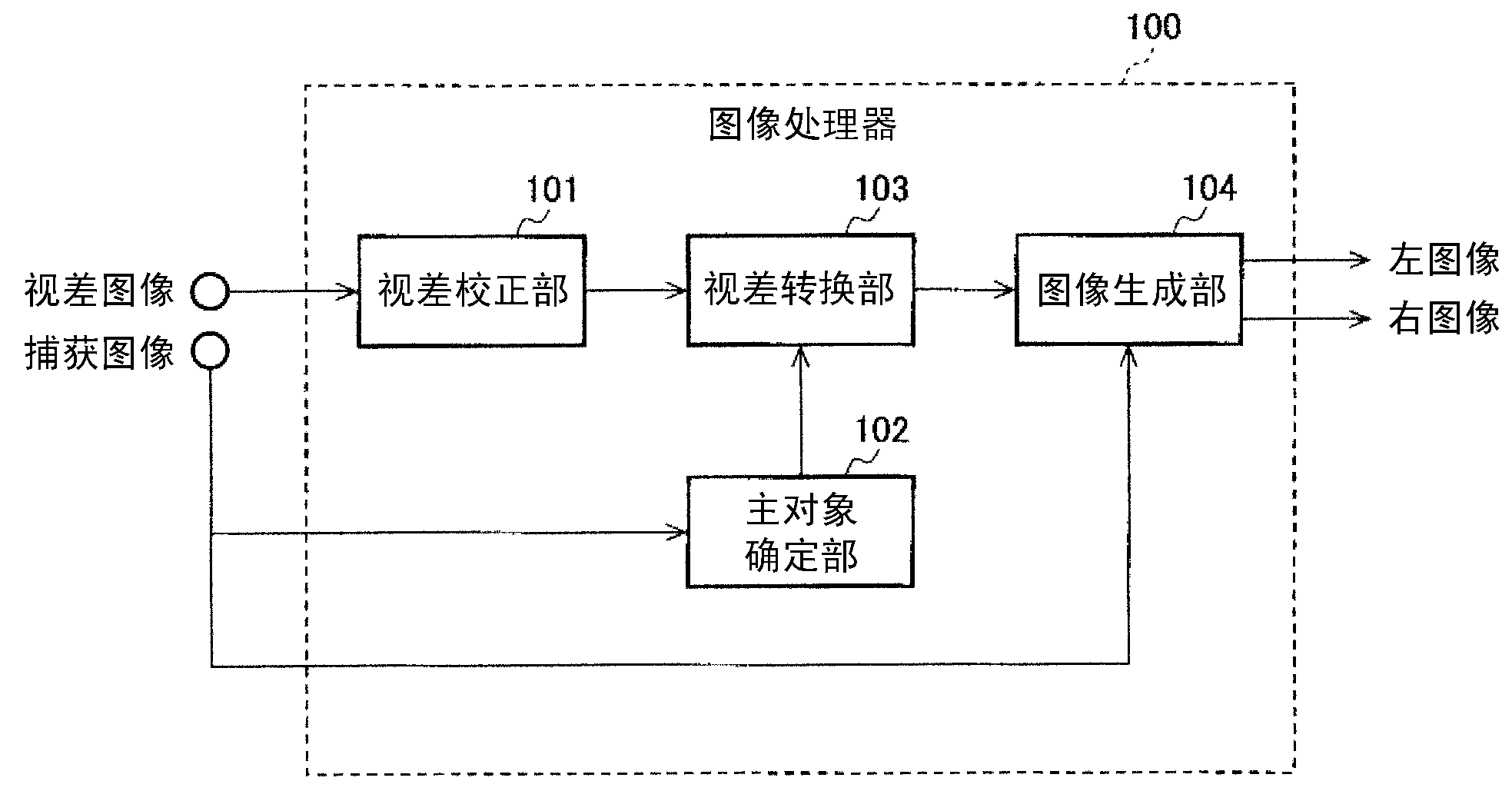

Image processor, image display apparatus, and imaging device

InactiveCN102939764AChanged depth perceptionAdjust the 3D effectTelevision system detailsColor television detailsImage processorImage display

Disclosed is an image processor which generates a three-dimensional image that is easy for an observer to view stereoscopically and thus does not tend to cause the observer to become fatigued, while easily adjusting the three-dimensional effect of any part of the three-dimensional image. A disparity correction unit (101) corrects disparity in a received disparity image to a given range, and outputs to a disparity conversion unit (103) the disparity image in which the corrected disparity has been stored. The disparity conversion unit (103) converts the disparity in the disparity image so that the disparity corresponding to the image of a main object determined by a main-object determination unit (102) has a given value, and outputs the disparity image obtained after the conversion to an image generation unit (104). The image generation unit (104) generates an image for the left eye and an image for the right eye based on the received disparity image and a received captured image, and outputs the images to a display apparatus. Consequently, the disparity is converted to enhance the three-dimensional effect of the main object.

Owner:SHARP KK

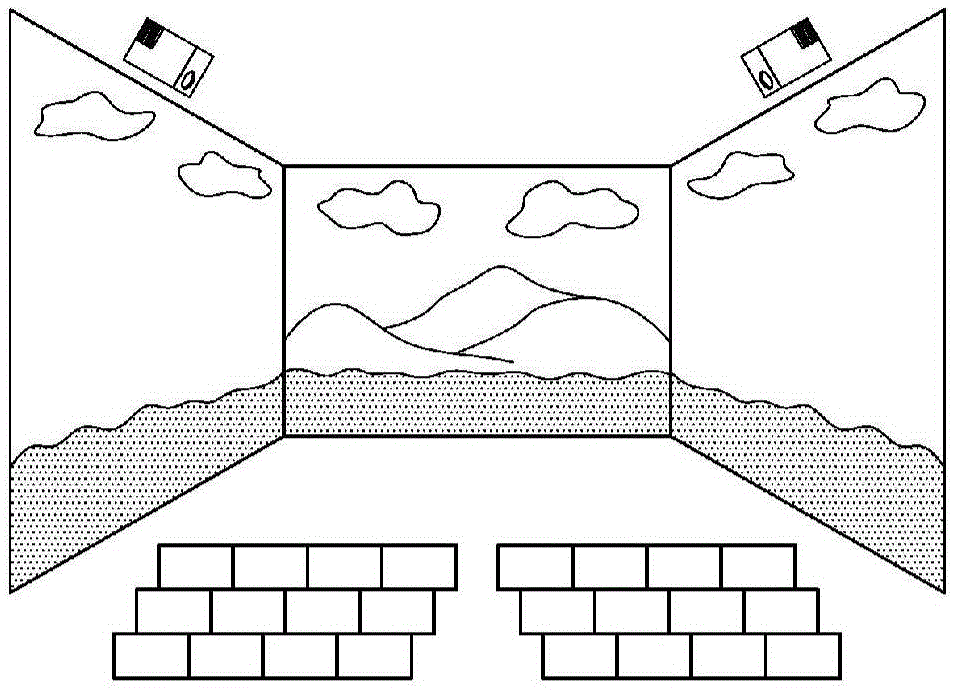

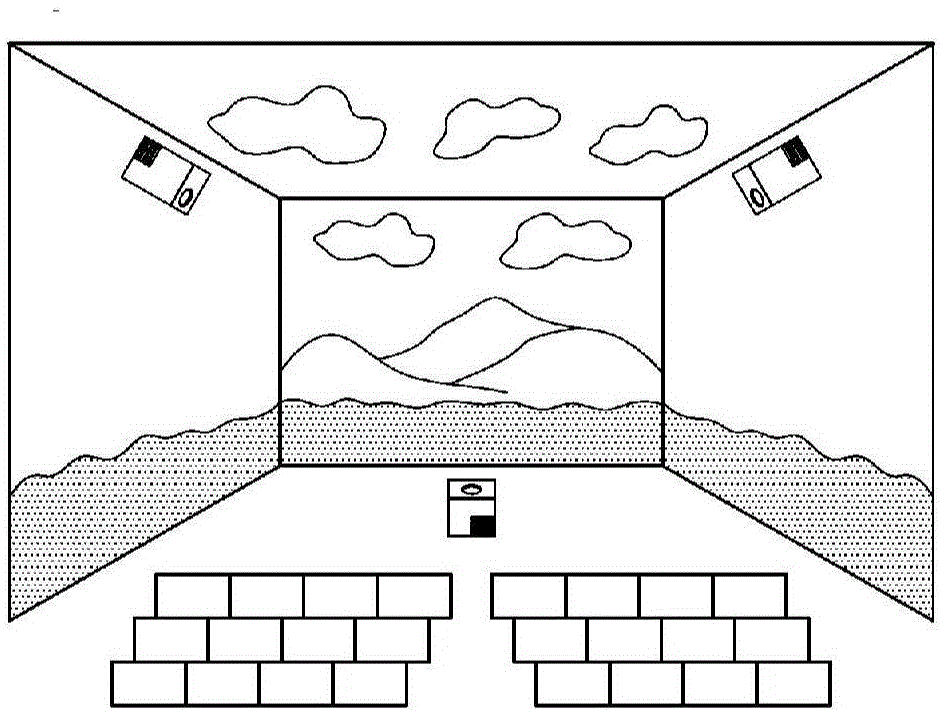

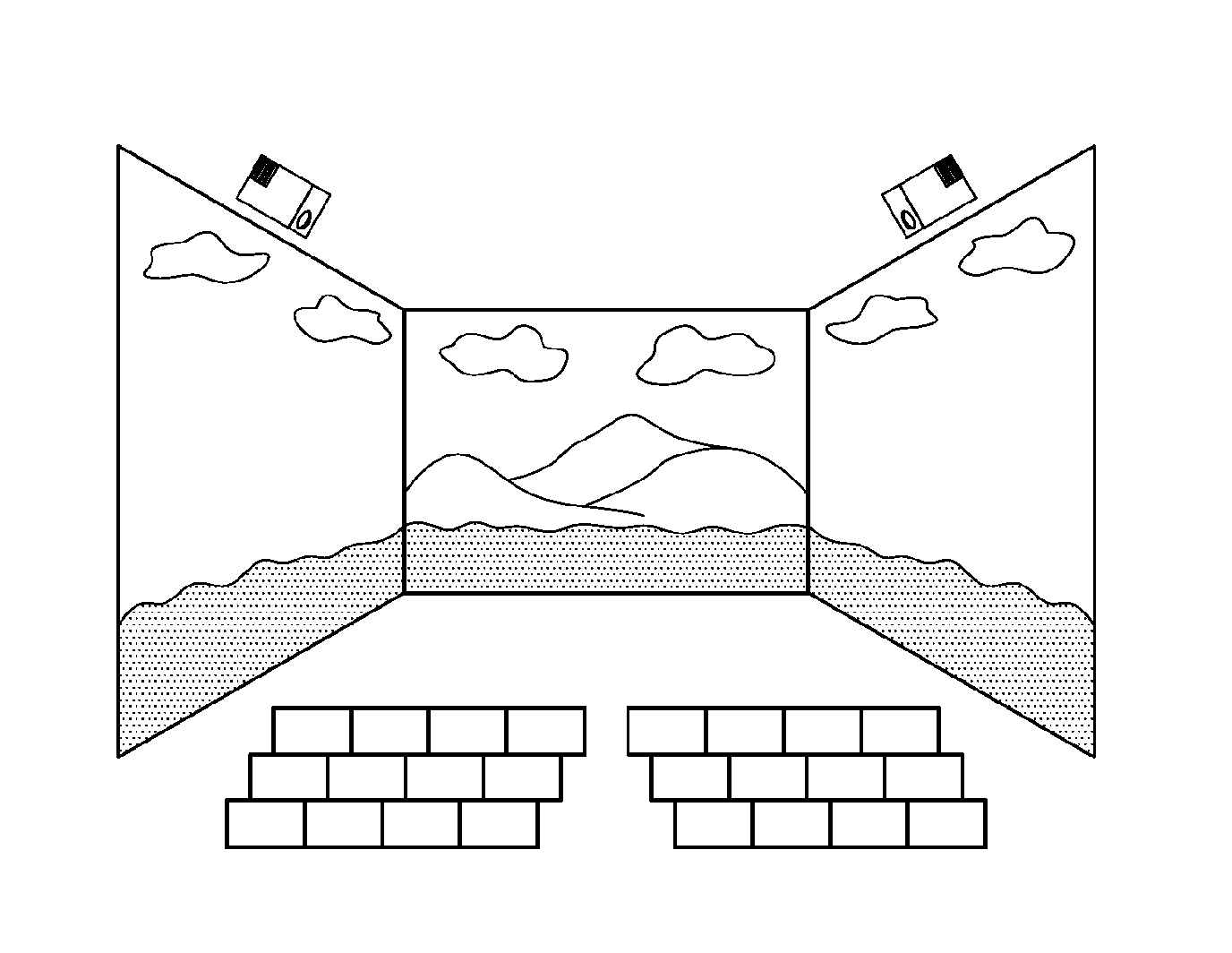

Multi-projection system with projection surface comprising non-solid material

InactiveCN105143975ALow heterogeneityStable formationProjectorsStereoscopic photographyProjection systemComputer science

The present invention provides a multi-projection system including a plurality of projection surfaces arranged in a single theater so as not to be parallel to each other, wherein the plurality of projection surfaces may comprise a projection surface including a non-solid material.

Owner:CJ CGV

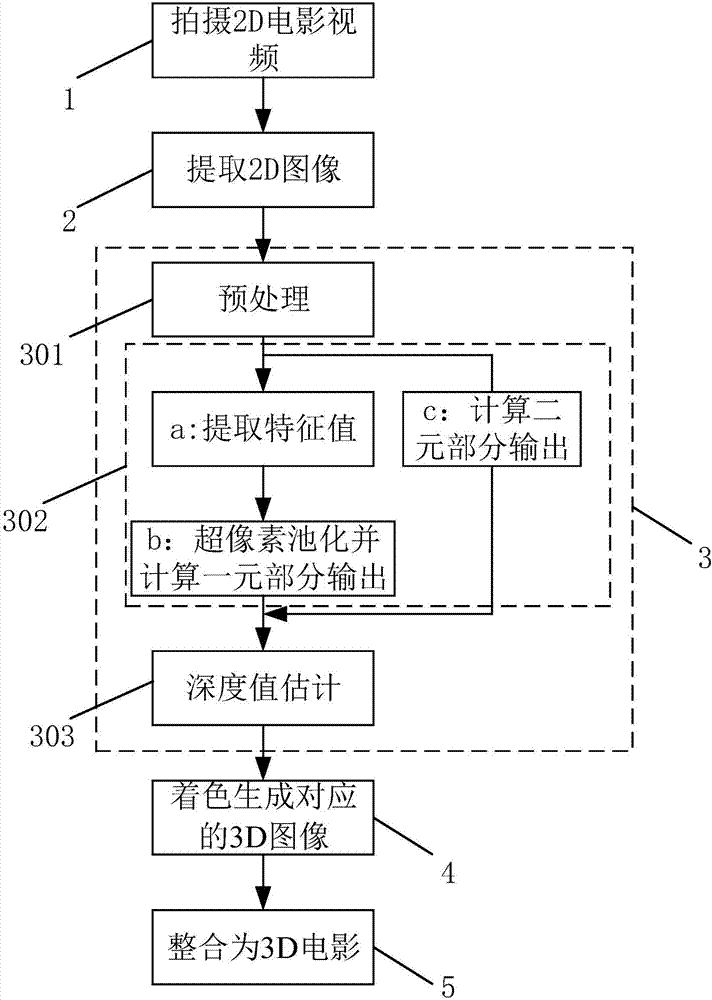

Method for converting 2D film into 3D film based on full convolutional neural network

InactiveCN107067452AAchieve conversionEasy to operateImage analysisDetails involving 3D image data3d imageConvolutional neural network

The invention relates to a method for converting a 2D film into a 3D film based on a full convolutional neural network. The method comprises the following steps: 1) extracting the 2D image of each frame in a photographed film's 2D video; 2) using the full convolutional neural network to extract the characteristics of the 2D image of each frame and calculating the depth value; 3) coloring the 2D image of each frame according to its depth value to generate a corresponding 3D image; and 4) integrating all the 3D images in succession to develop a 3D film. Compared with the prior art, the method can well fit the scenes; the depth estimation quality is high; the calculation speed is rapid; and the method can be efficiently used for the conversion of a 2D film to a 3D film in various scenes.

Owner:TONGJI UNIV

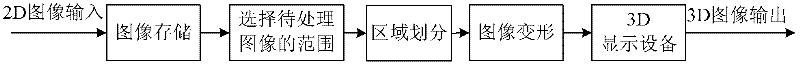

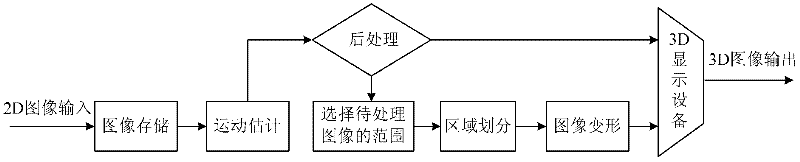

Image processing method and device

InactiveCN102421003AAvoid the problem that the 3D effect is not obviousEfficient conversionSteroscopic systemsImaging processingImage transfer

The invention provides an image processing method and device. The image processing method comprises the following steps of: A, storing a 2D (two-dimensional) image of a current frame; B, selecting a range of an image to be processed from the stored 2D image of the current frame; C, carrying out linear zooming and nonlinear zooming respectively on the image to be processed in the range of the image to be processed, selected in the step B, so as to realize 2D image deformation, and taking the deformed 2D image as input images for a left eye and a right eye respectively; and D, transmitting the input images of the left eye and the right eye to 3D (three-dimensional) display equipment. The method and the device provided by the invention can realize real-time conversion from the 2D image to the 3D image, and the 3D effect is obvious.

Owner:POWERLAYER MICROSYST HLDG

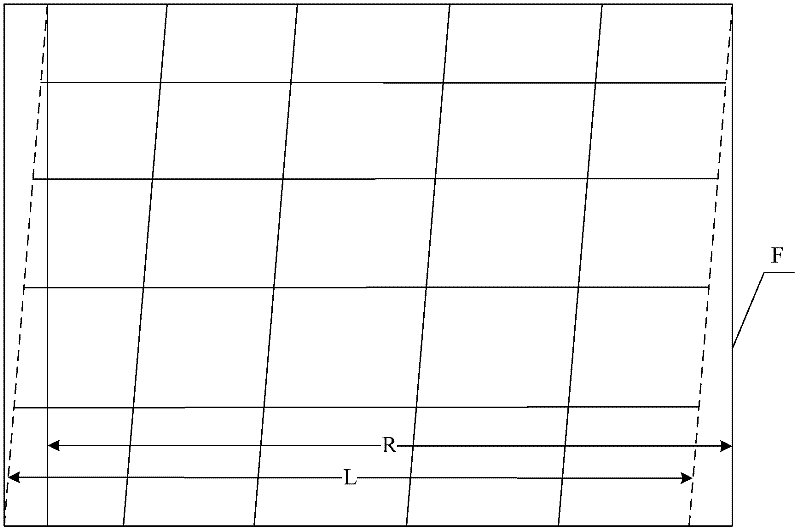

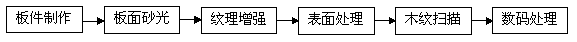

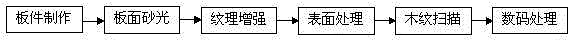

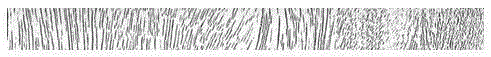

Manufacturing method for high-precision wood grain image

InactiveCN104210005AImprove textureTexture highlightsDecorative surface effectsWood working apparatusMaterials scienceWood grain

The invention provides a manufacturing method for a high-precision wood grain image. The manufacturing method comprises the following steps: (1) manufacturing a plate; (2) sanding the surface of the plate; (3) enhancing grains; (4) carrying out surface treatment; (5) scanning wood grains; (6) carrying out digital processing. The manufacturing method has the advantages that the high-precision large-width wood grain texture image is obtained by carrying out enhanced treatment on surface grains on a wood base material and the layering of wood grains is better; a 3D (Three Dimensional) effect represented by the plane image is stronger; particularly, a vivid 3D wood grain effect is manufactured by matching an existing spray printing process.

Owner:GUANGDONG YIHUA TIMBER IND +1

Method and system for generating multi-projection images

InactiveUS20160127723A1Enhanced 3D effectMaximize immersionTelevision system detailsColor television detailsViewpointsProjection image

Owner:CJ CGV

Region compensation method of multi-view naked eye 3D display based on cylindrical mirror grating

ActiveCN107801019AReduce distortionEnhanced 3D effectSteroscopic systemsOptical elementsGratingDisplay device

The invention relates to the field of naked eye 3D display, especially to a region compensation method of multi-view naked eye 3D display based on the cylindrical mirror grating. The region compensation method of the multi-view naked eye 3D display based on the cylindrical mirror grating comprises the following steps: dividing the screen into a plurality of regions according to the design parameter features of the naked eye 3D display device; and debugging each area as an independent sub-screen. The region compensation method of the multi-view naked eye 3D display based on the cylindrical mirror grating provided by the invention can reduce the deformation of the liquid crystal screen and the deformation of the grating, and can reduce the affect of the 3D effect caused by the unevenness generated by the lamination of the liquid crystal screen and the grating, therefore, the display effect of the naked eye 3D is improved.

Owner:广州大眼猫医疗器械科技有限公司

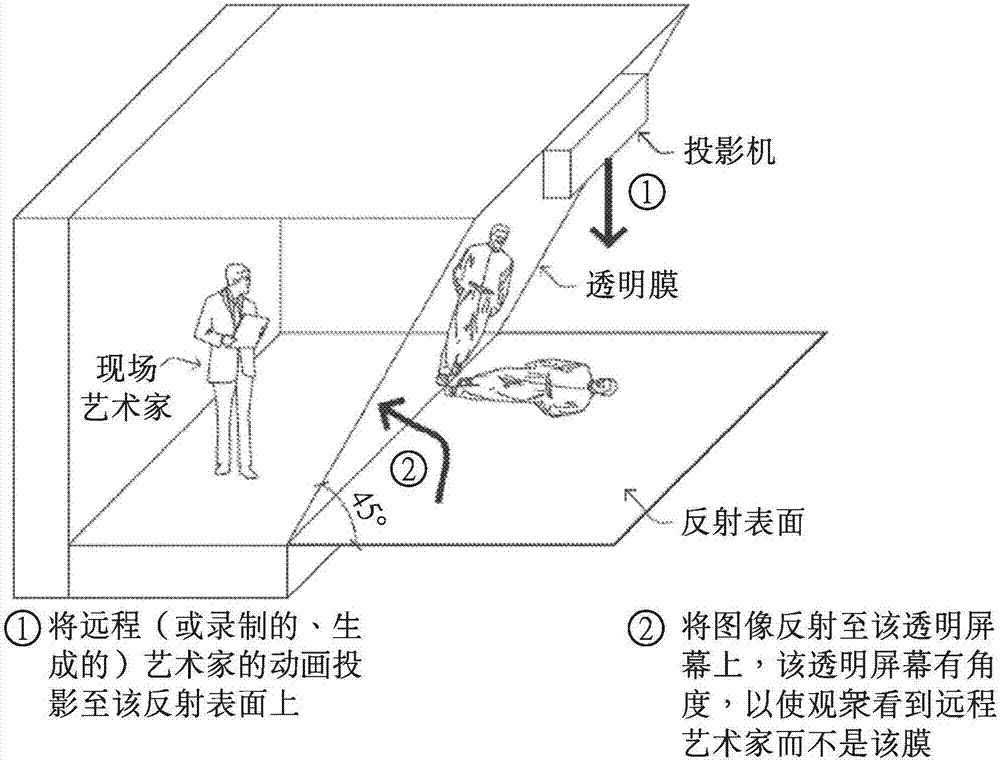

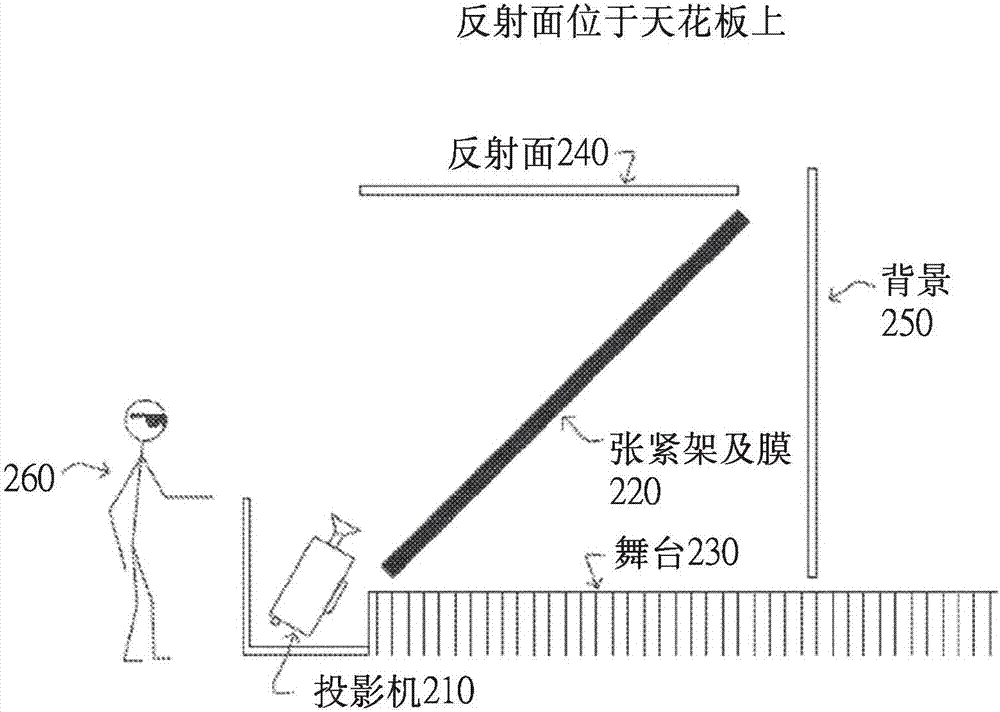

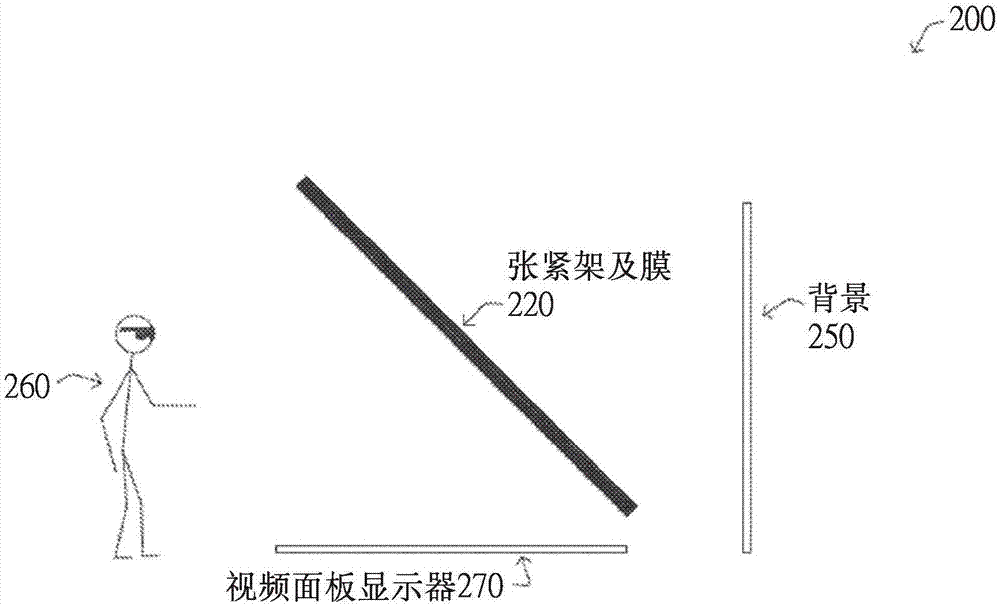

Three-dimensional image source for enhanced pepper's ghost illusion

InactiveCN107533184ARealistic 3D effectAdding three-dimensional (3D) effectsTelevision system detailsBuilt-on/built-in screen projectors3d shapesDisplay device

Systems and methods herein are directed to three-dimensional image sources for an enhanced Pepper's Ghost Illusion. In one embodiment, a contoured bounce is described, allowing for contorting a bounceto different shapes, giving it enhanced three- dimensional (3D) effect. For instance, the bounce may include certain topography (raised portions), or else may actually comprise various 3D shapes (e.g., cubes, semi-spheres, etc.). In another embodiment, a multi-level image source is described, allowing for multiple image sources (e.g., projected bounces and / or panel displays) to be used and placedat different heights with respect to a transparent viewing screen, thus projecting images that appear at various depths, increasing the three-dimensional (3D) effect of the Pepper's Ghost Illusion. In addition, in one embodiment, the heights of the image sources may be adjusted (e.g., dynamically), making corresponding holographic images change their depth perspective to an audience, further enhancing the 3D effect.

Owner:VENTANA 3D

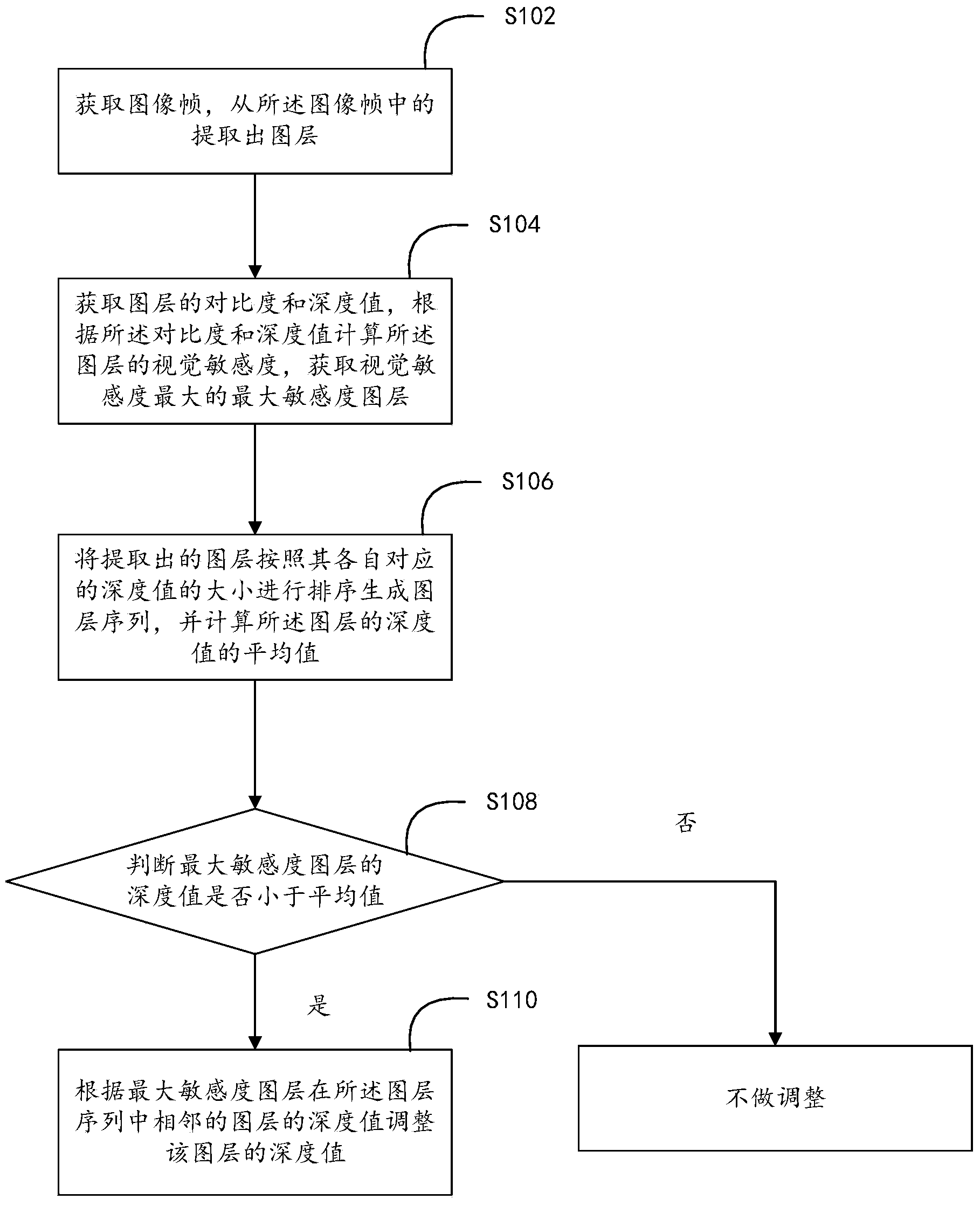

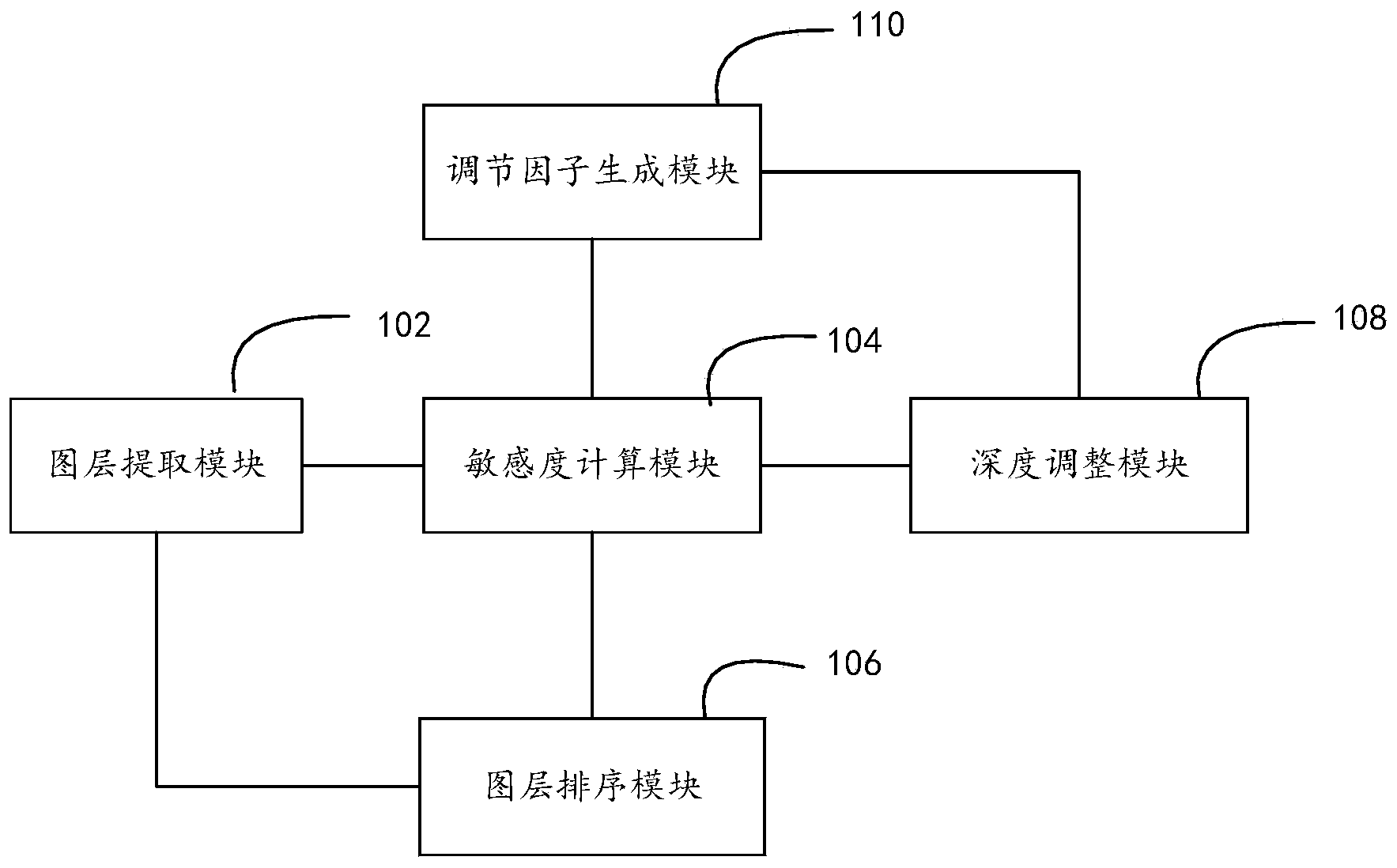

Layer adjusting method and device for converting 2D image to 3D image

InactiveCN104240179ADoes not interfere with presentationEnhanced 3D effectGeometric image transformation3d imageVisual perception

The invention provides a layer adjusting method for converting a 2D image to a 3D image. The method includes the steps of obtaining an image frame, extracting layers from the image frame, obtaining the contrast ratios and the depth values of the layers, calculating the vision sensitivity of each layer according to the contrast ratios and the depth values, obtaining the layer with the maximum vision sensitivity, ranking the extracted layers according to the depth values corresponding to the layers so as to generate a layer sequence, calculating the average value of the depth values of the layers, judging whether the depth value of the layer with the maximum vision sensitivity is smaller than the average value or not, and if yes, adjusting the depth value of the layer with the maximum vision sensitivity according to the depth values of the layers, adjacent to the layer with the maximum vision sensitivity, in the layer sequence. The invention further provides a layer adjusting device for converting the 2D image to the 3D image. The layer adjusting method and device for converting the 2D image to the 3D image can improve the 3D effect.

Owner:深圳深讯和科技有限公司

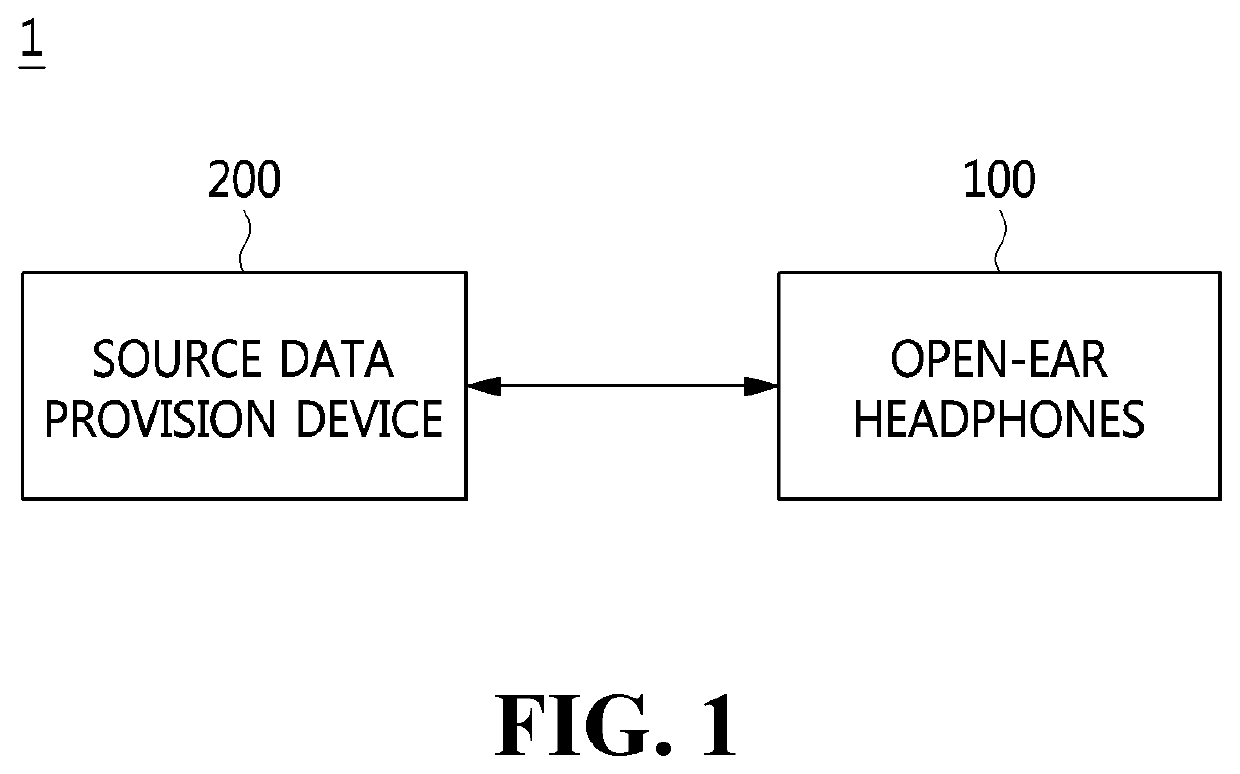

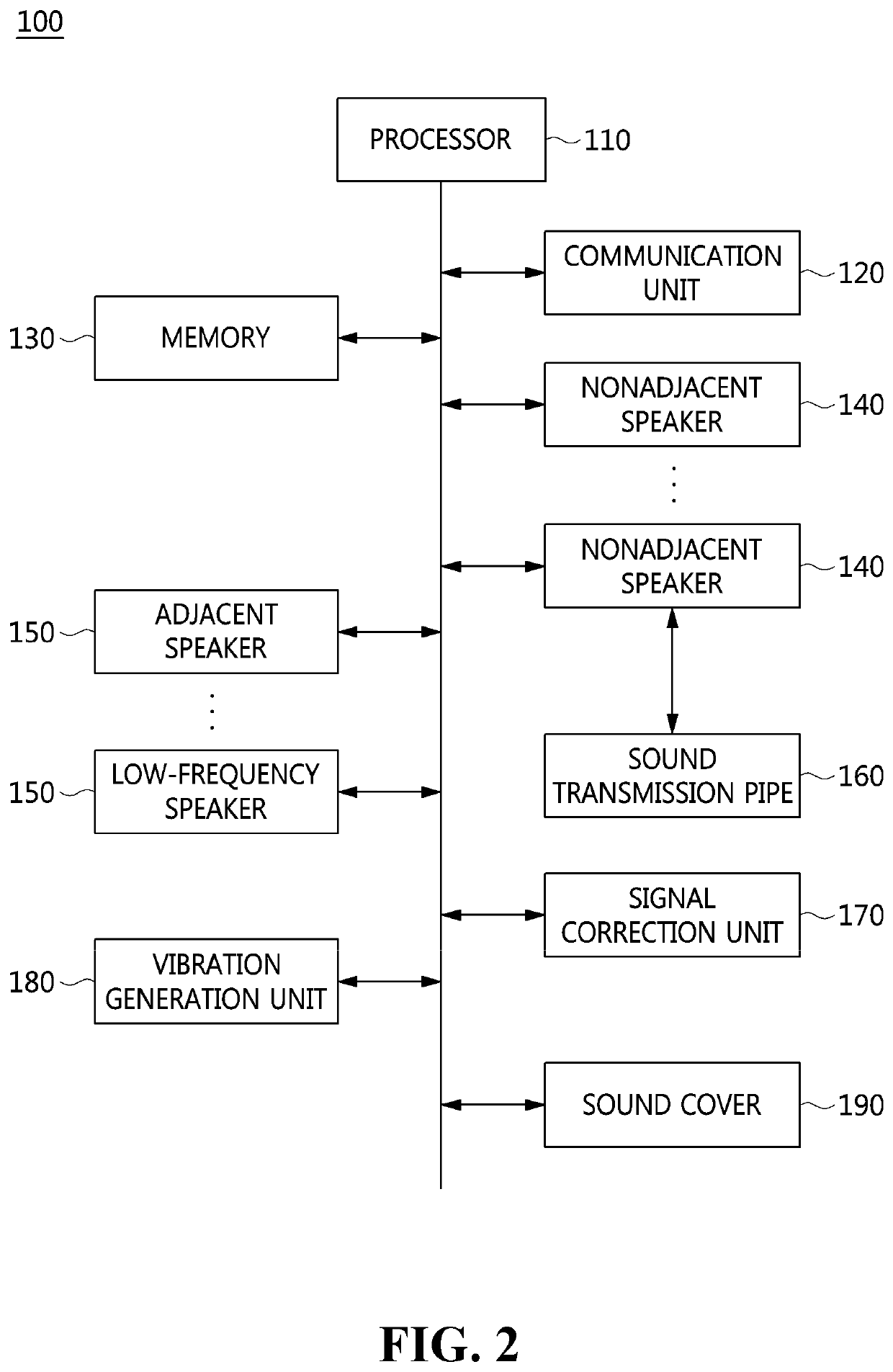

Multi-channel sound implementation device using open-ear headphones and method therefor

InactiveUS20200366990A1Easy constructionAdd channelFrequency response correctionFrequency/directions obtaining arrangementsCommunication unitHeadphones

A multi-channel sound implementation device comprising: a source data analysis unit for analyzing source data; a speaker system analysis unit; a headphone information analysis unit for analyzing information on at least one or more open-ear headphones for outputting sound in a state where the headphones are spaced apart from the ears of a user; an audio signal generation unit for, by using information on the audio signals, information on the speaker system and the information on the open-ear headphones, generating speaker audio signals having at least one channel, which may be reproduced in the speaker system, and generating headphone audio signals, which may be reproduced in the open-ear headphones; and a communication unit for transmitting the speaker audio signals to the speaker system, and transmitting the headphone audio signals to the respective open-ear headphones to which the headphone audio signals correspond.

Owner:GOO BONN HEE +3

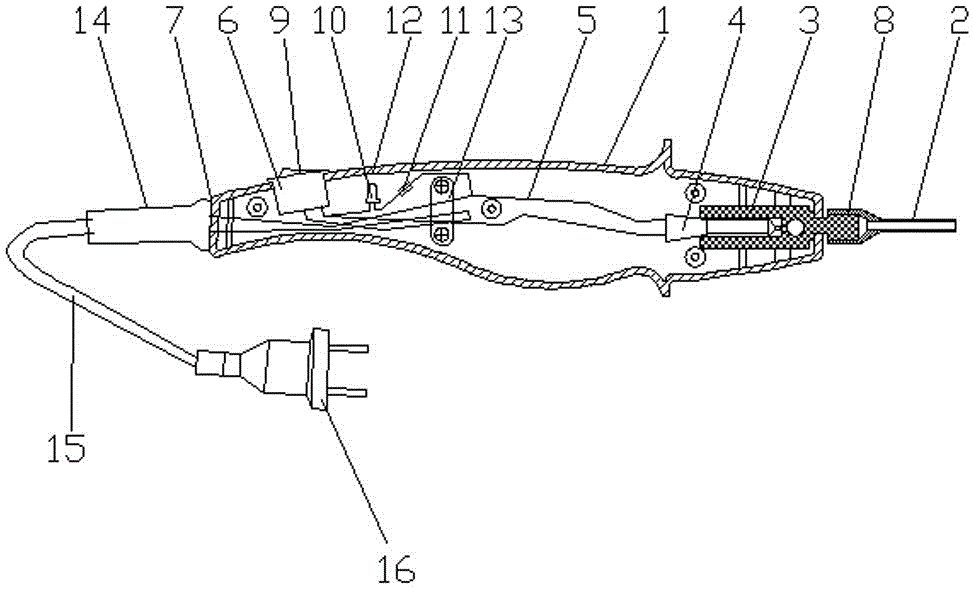

Hot-melting crayon

InactiveCN105082828AAvoid display effectsExcellent adhesionNon-propelling pencilsOther artistic work equipmentsThermodynamicsEngineering

The invention relates to a hot-melting crayon which comprises a casing. A paintbrush point is arranged at the front end of the casing, a U-shaped heating head in the casing is arranged at the rear end of the paintbrush point, and a piece of insulating paper is inserted into a U-shaped groove of the U-shaped heating head; a lead at the rear end of the U-shaped heating head can be partially wrapped by the insulating paper, two leads are connected to the other end of the U-shaped heating head, and the other end of the U-shaped heating head is connected with a switch and a power socket at the tail end of the casing through the two leads; and the switch is further provided with another lead and connected with the power socket through the lead to form a closed circuit. A heating method is that the heating head is heated by an inner PTC heating core, heat is transferred to the paintbrush point, wax can be melted by the heat on the paintbrush point and adsorbed in the paintbrush point, and the melted wax can be used for painting on a base material in a self flow manner. Due to the fact that the wax is melted, the attachment force of the wax on the base material is higher, and the color is brighter. Thus, the problems of the attachment force of the wax on the base material and the display effect on the base material are solved. Furthermore, the 3D effect is also achieved.

Owner:SHAOGUAN OUYATE ELECTRONICS PROD

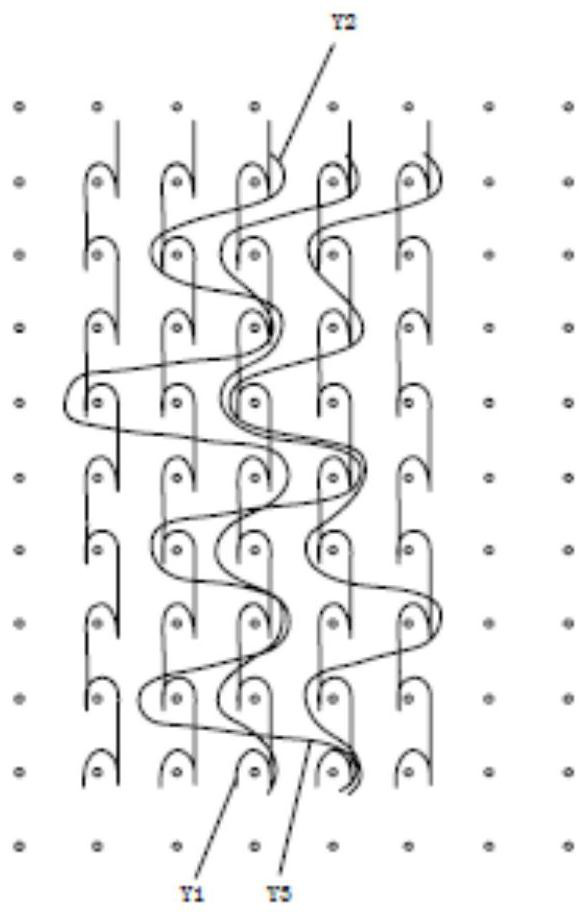

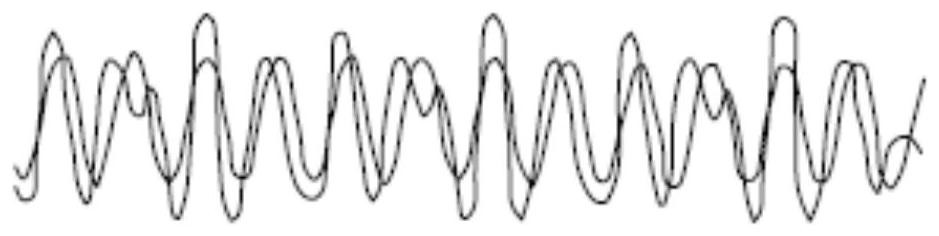

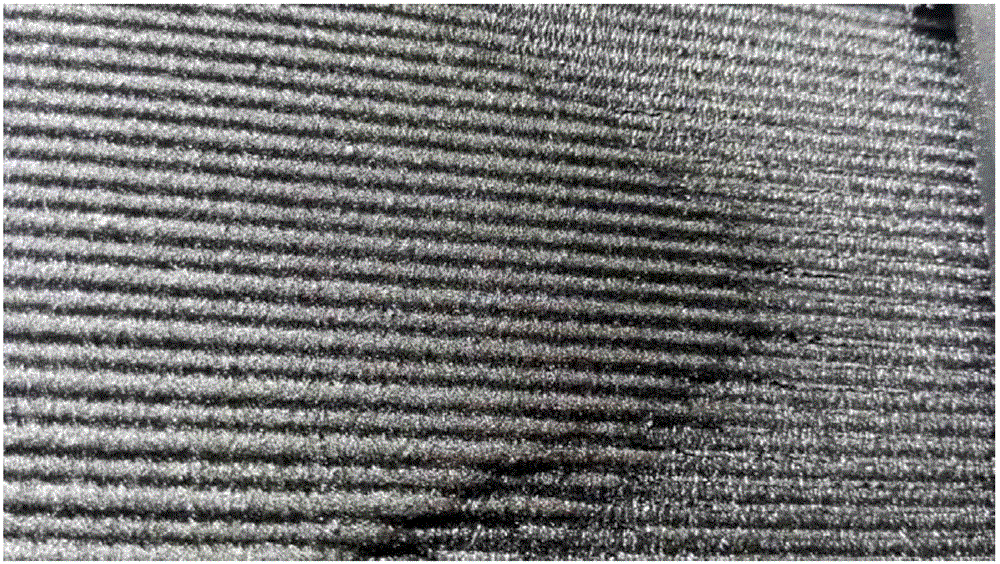

Recyclable four-side elastic lace fabric with enhanced 3D effect and preparation method thereof

PendingCN112726009AImprove the three-dimensional effectNo spandex yellowing phenomenonWarp knittingHeating/cooling textile fabricsYarnPolymer science

The invention relates to a recyclable four-side elastic lace fabric with the enhanced 3D effect and a preparation method thereof. The fabric comprises a fabric body; a pattern is woven on the fabric body; the fabric body is woven by three kinds of yarns Y1, Y2 and Y3 in a matched way; the yarns Y1 and Y2 are elastic composite yarns which are made of the same material and do not contain spandex; the yarns Y3 are made of the same material as the yarns Y1 and Y2 and are elastic composite yarns free of spandex, elementary substance elastic yarns free of spandex or non-elastic yarns; the yarns Y1 are woven according to a chain stitch structure; the yarns Y2 are woven according to a weft insertion jacquard weave structure; the yarns Y1 and the yarns Y2 are woven to form a main body structure of the fabric body; and the yarns Y3 are woven according to a variable weft insertion or variable looping structure to form the pattern. The fabric is good in warp and weft elasticity, and the spandex yellowing phenomenon of a traditional elastic fabric is avoided; and the material is single, the recovery is convenient and fast, the recovery efficiency can be greatly improved, and the recovery cost is reduced.

Owner:BEST PACIFIC TEXTILE

Method for making high-precision wood grain image

InactiveCN104210005BGood sense of hierarchyEnhanced 3D effectDecorative surface effectsWood working apparatusMaterials scienceSurface finishing

Owner:GUANGDONG YIHUA TIMBER IND +1

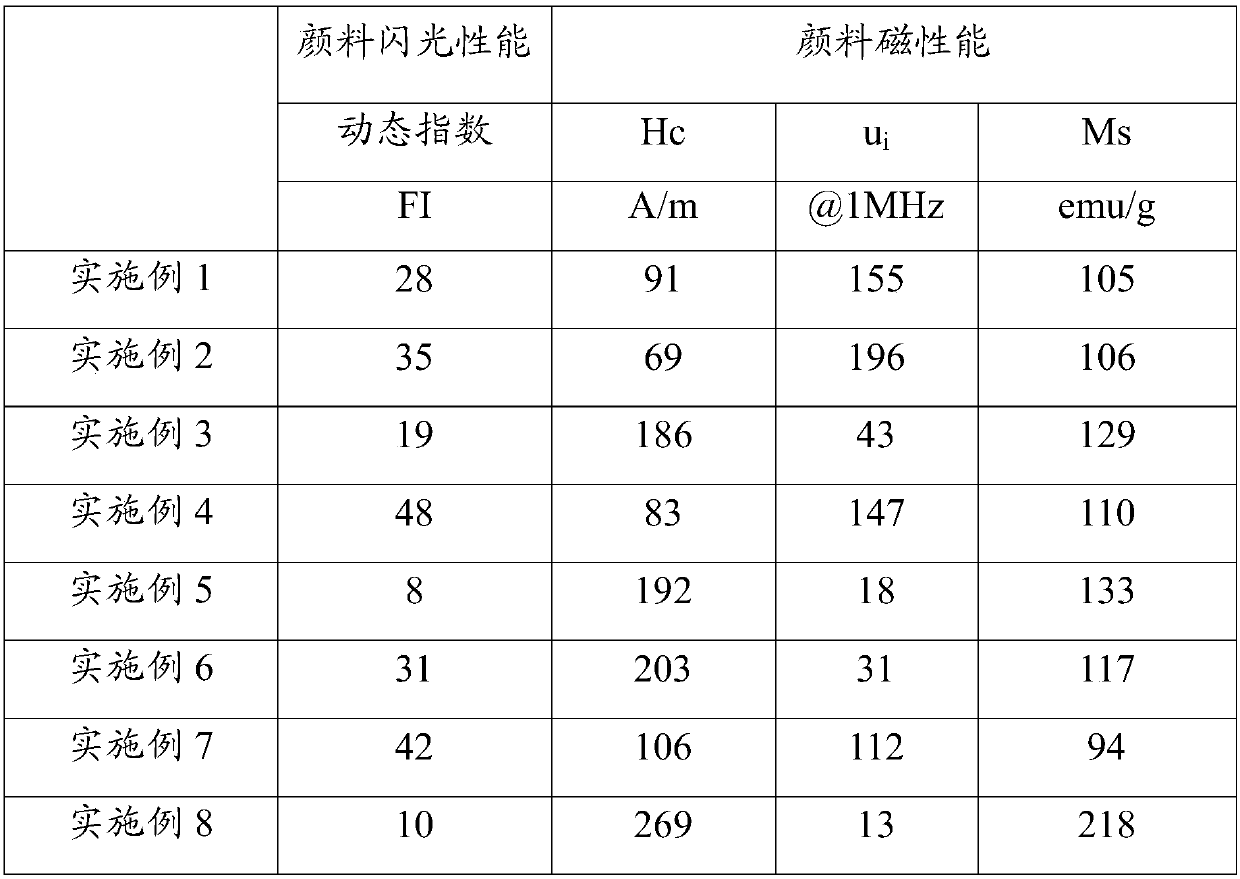

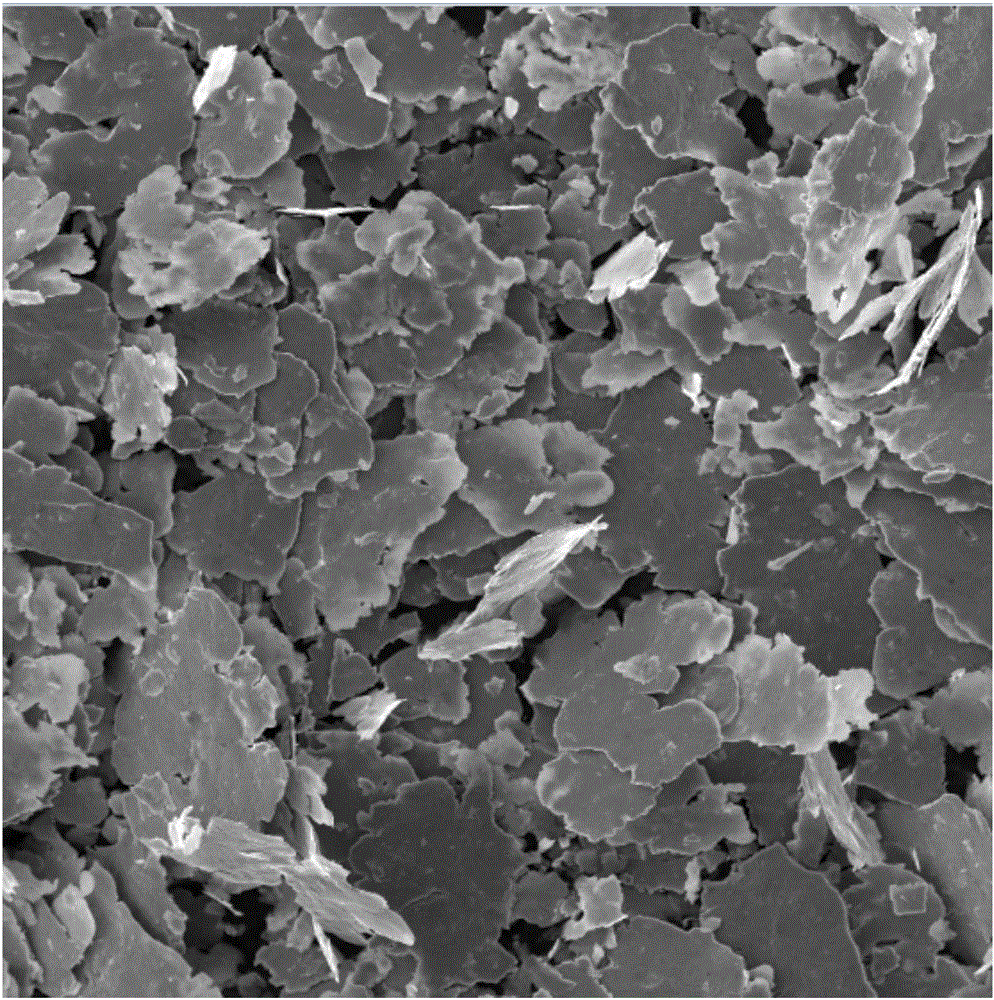

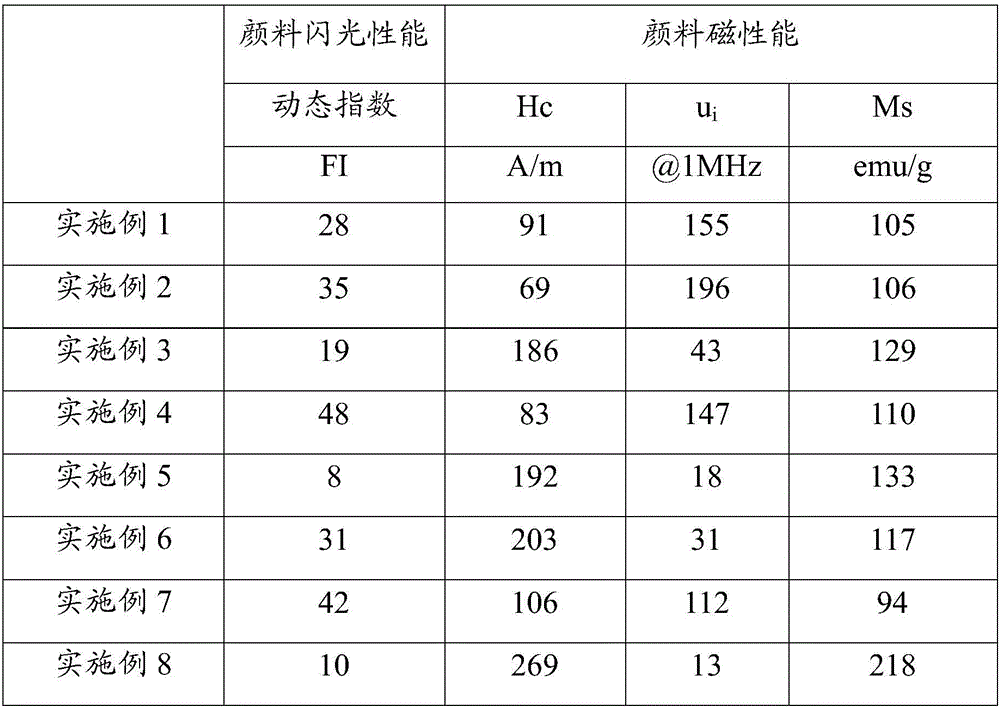

Substrateless magnetic glittering pigment and preparation method and application thereof

ActiveCN105838117BStrong magnetismSignificant flopInorganic material magnetismPigment physical treatmentApparent densityMicrometer

The invention provides base-material-free magnetic flash pigment .The base-material-free magnetic flash pigment is flaky powder made of a metal soft magnetic material, the average particle size of the base-material-free magnetic flash pigment is 5-200 micrometers, the apparent density is 0.2-1.0 g / cm<3>, and the diameter-thickness ratio is 10-100 .The base-material-free magnetic flash pigment has high permeability and a remarkable angle-dependent optical effect and can be used for decoration and resisting electromagnetic interference .The invention further provides a preparing method and application of the base-material-free magnetic flash pigment.

Owner:HUNAN NELKIN MATERIAL TECH CO LTD

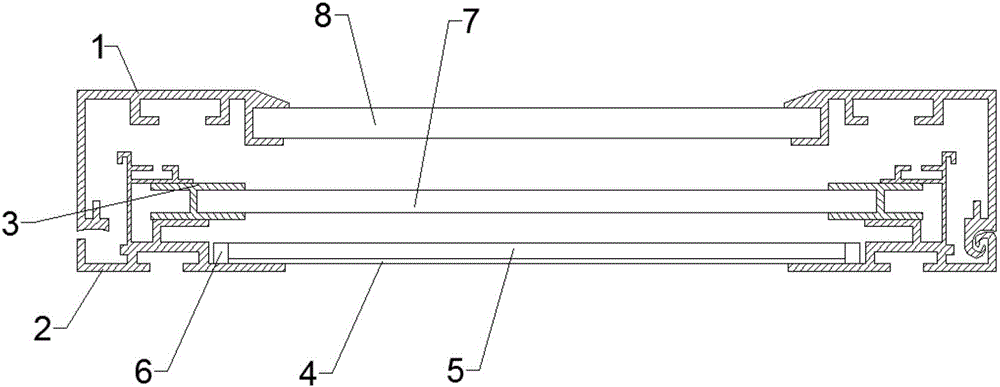

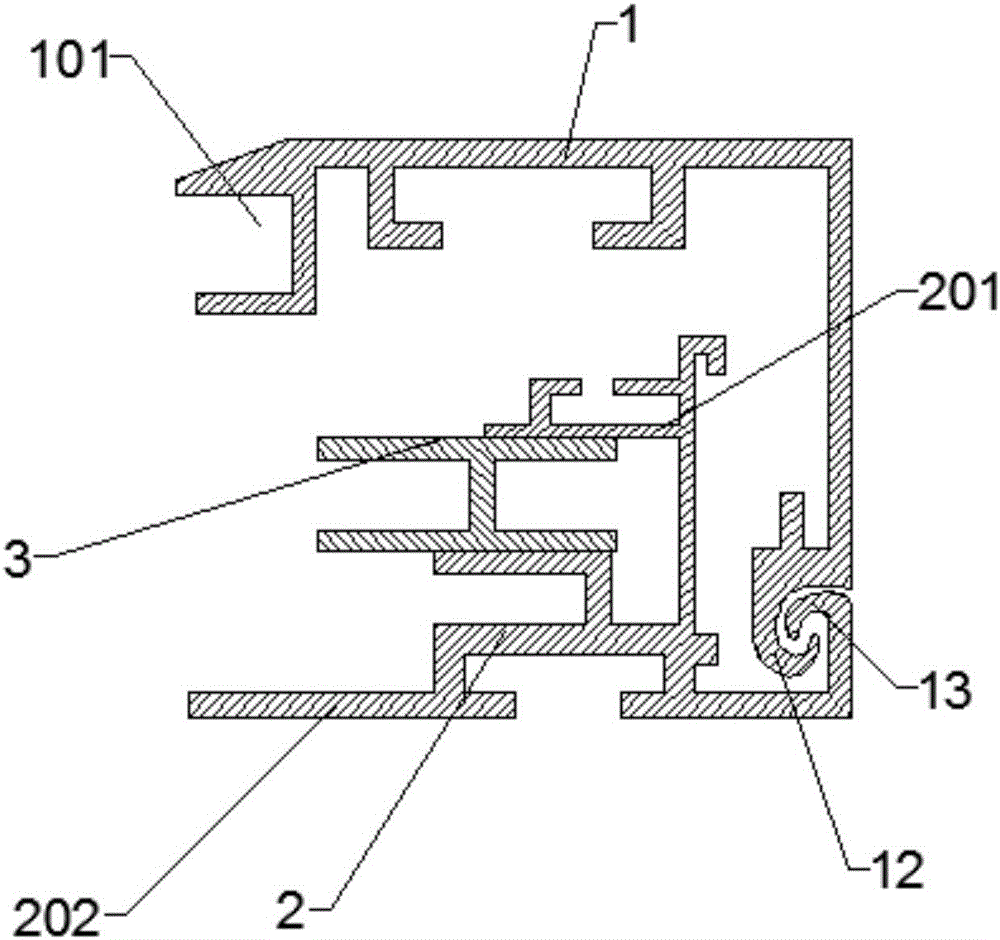

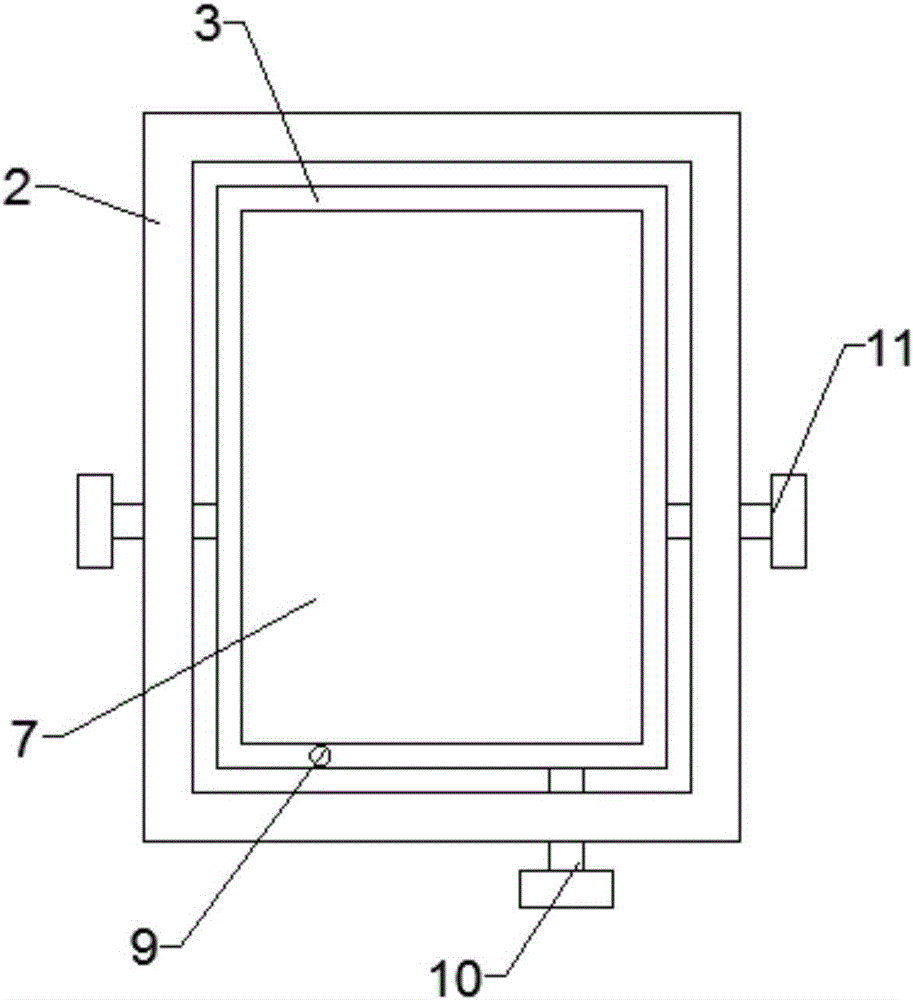

Picture replaceable 3D light box

The invention discloses a picture replaceable 3D light box. The light box comprises a cover plate, a bottom frame, a picture attaching glass framework, a backlight plate, a light guide plate, a light emitting device, picture attaching glass and optical grating attaching glass. According to the picture replaceable 3D light box, when a 3D picture needs to be replaced, people only need to remove the cover plate, tear down the picture on the picture attaching glass and attach a new picture; in this way, the cost of original organic glass between a printed picture and an optical grating is omitted, an optical grating film can be reused, and cost is saved; furthermore, the whole installation process is simple, and direct on-site installation can be achieved.

Owner:广东康得新创意设计有限公司

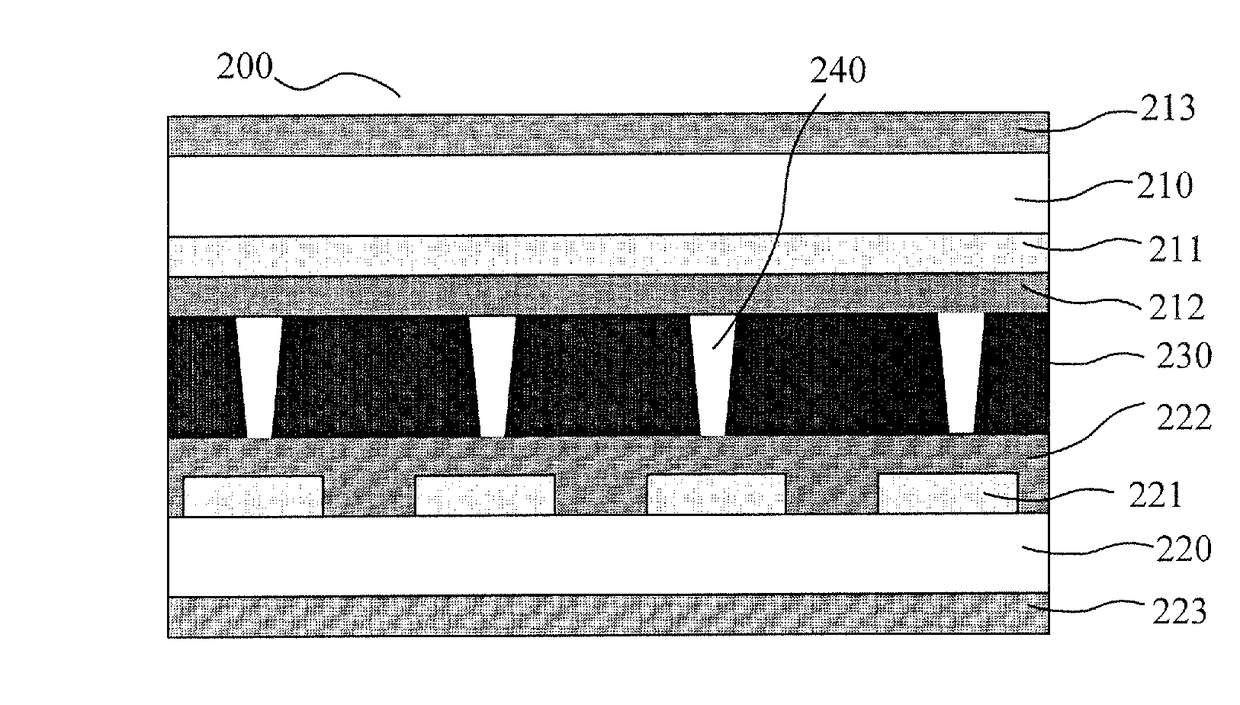

Liquid crystal slit grating and stereoscopic display device

ActiveUS9632325B2Easy to controlEnhanced 3D effectNon-linear opticsOptical elementsGratingDisplay device

The present invention discloses a liquid crystal slit grating and a stereoscopic display device, the liquid crystal slit grating includes a first grating substrate and a second grating substrate facing each other, and a plurality of photo spacers supporting between the first grating substrate and the second grating substrate; the stereoscopic display device includes a display panel and said liquid crystal slit grating which is parallel to each other. The liquid crystal slit grating of the present invention provides conditions for accurately controlling effects of the photo spacers on light transmittance or accurately controlling crosstalk caused by the photo spacers. The stereoscopic display device of the present invention provides conditions for improving 3D effect of stereoscopic display device during three dimensionally displaying.

Owner:BOE TECH GRP CO LTD

Base-material-free magnetic flash pigment and preparing method and application thereof

ActiveCN105838117AStrong magnetismSignificant flopInorganic material magnetismPigment physical treatmentMicrometerElectromagnetic interference

The invention provides base-material-free magnetic flash pigment .The base-material-free magnetic flash pigment is flaky powder made of a metal soft magnetic material, the average particle size of the base-material-free magnetic flash pigment is 5-200 micrometers, the apparent density is 0.2-1.0 g / cm<3>, and the diameter-thickness ratio is 10-100 .The base-material-free magnetic flash pigment has high permeability and a remarkable angle-dependent optical effect and can be used for decoration and resisting electromagnetic interference .The invention further provides a preparing method and application of the base-material-free magnetic flash pigment.

Owner:湖南纳金新材料技术有限公司

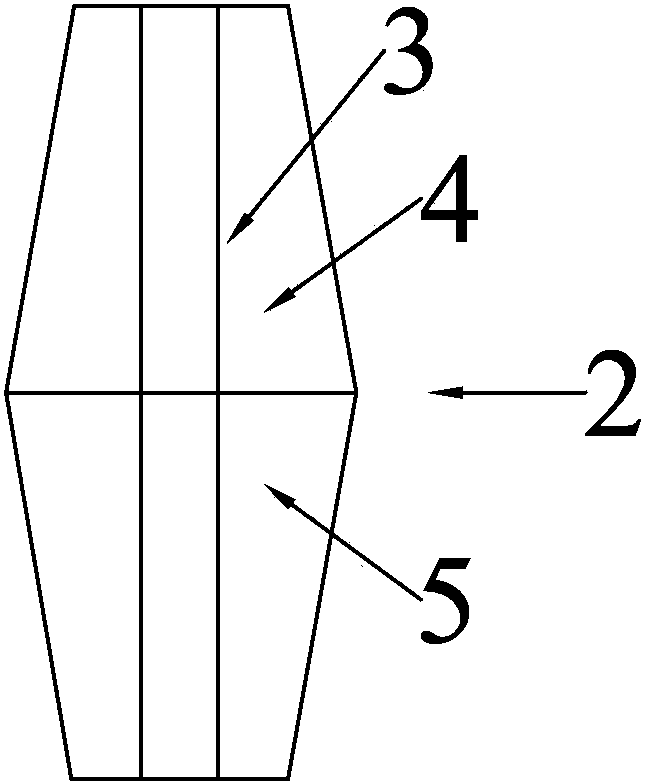

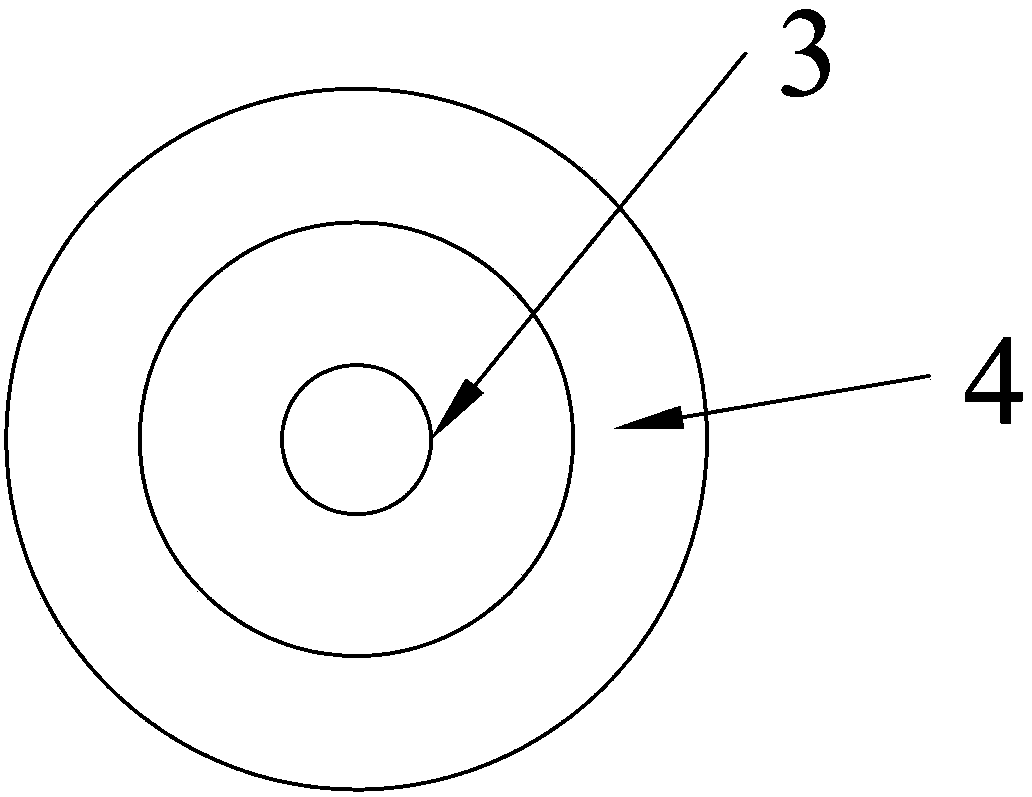

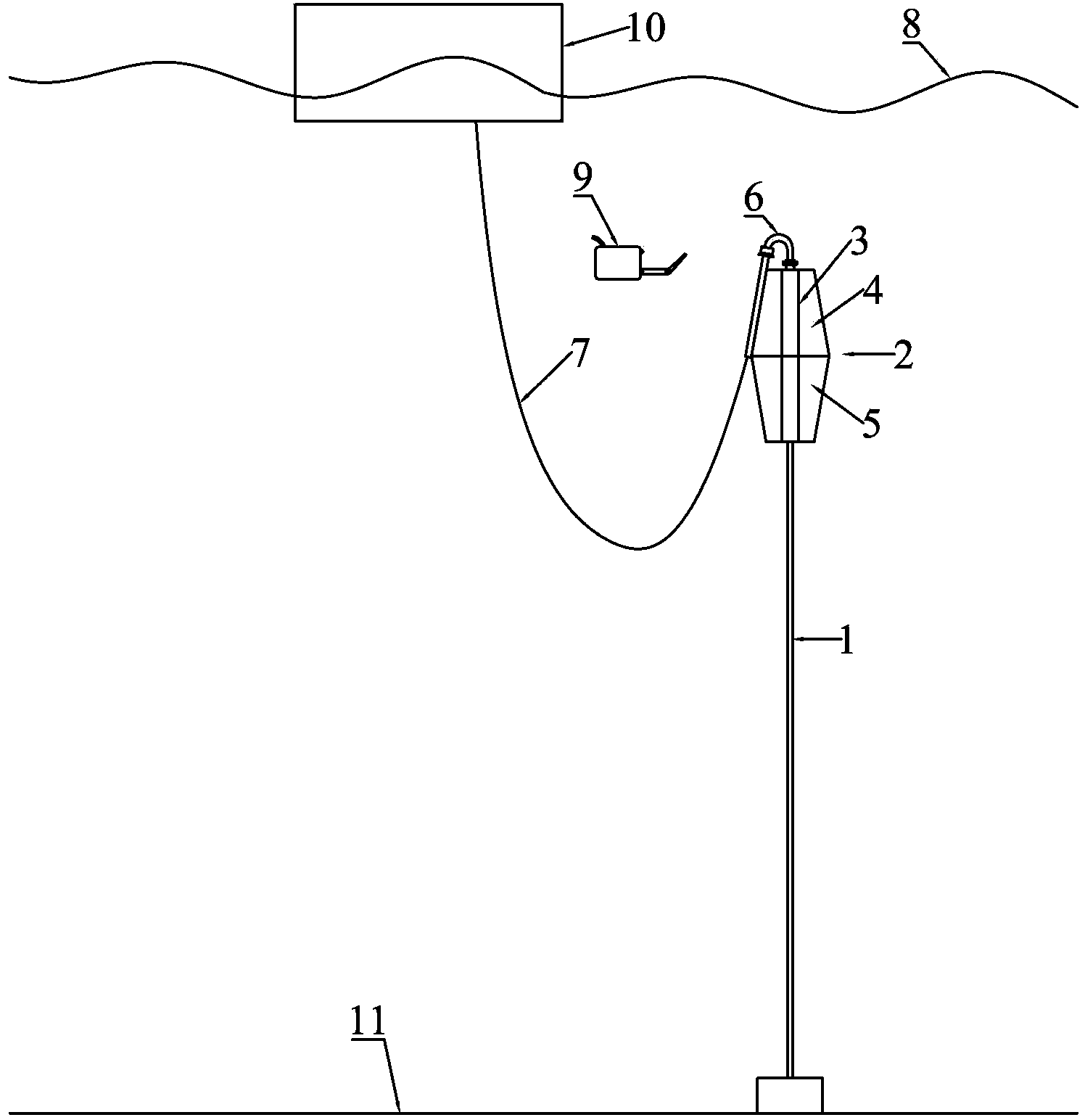

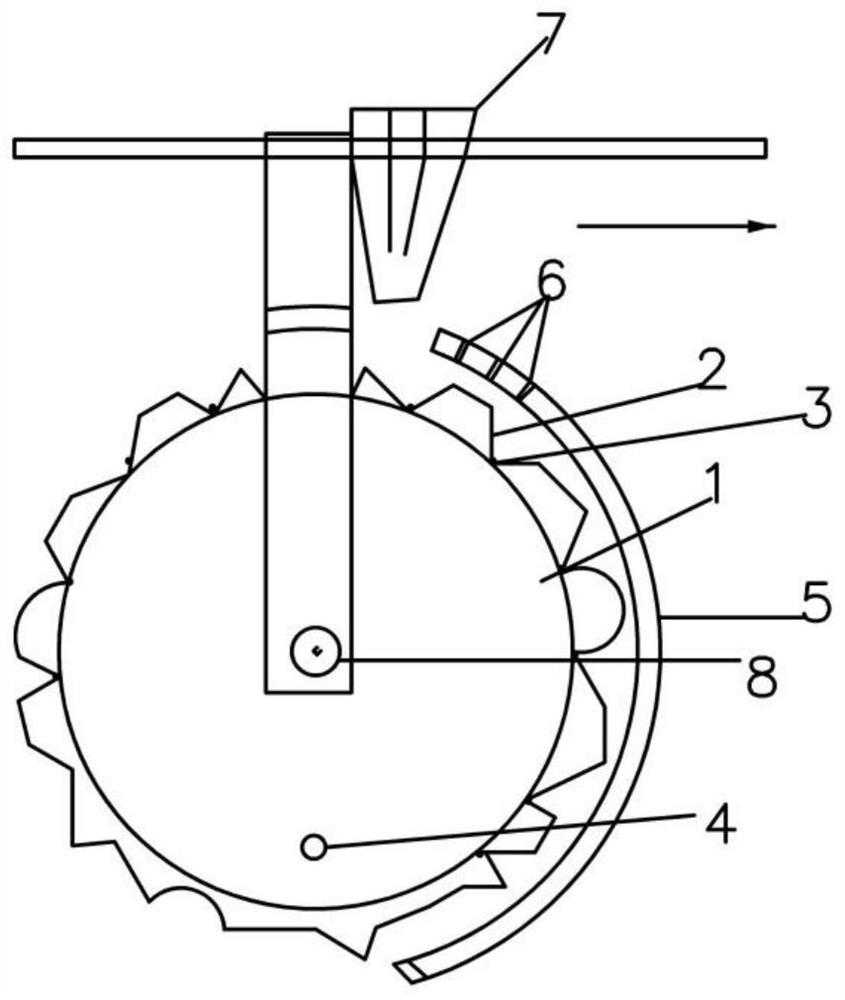

Diving buoyancy tube

InactiveCN103397865AEnhanced 3D effectNo obvious vortex phenomenonBorehole/well accessoriesBuoyWater dynamics

The invention discloses a diving buoyancy tube. The diving buoyancy tube comprises an upper part buoy and a lower part buoy, wherein the upper part buoy is in a shape of a round platform; the lower part buoy is in a shape of an inverted round platform; the bottom surface area of the upper part buoy is the same as the top surface area of the lower part buoy; the bottom surface of the upper part buoy is fixedly connected to the top surface of the lower part buoy so as to form a whole; central shafts of both the upper part buoy and the lower part buoy are in the same straight line. According to the invention, the upper part buoy and the lower part buoy adopt round platform structural designs, and a traditional cylindrical buoyancy tube is designed to be drum-shaped, so that a three-dimensional effect of the streaming on the diving buoyancy tube is enhanced, eddy flaking off of a wake field is effectively inhibited, and a better water dynamic stability is provided; a gooseneck elbow device is installed on the outer edge of the diving buoyancy tube, so that the installation process of a flexible cross-over tube is simplified, and the risk of the collision of an ROV and the buoyancy tube is reduced.

Owner:DALIAN UNIV OF TECH

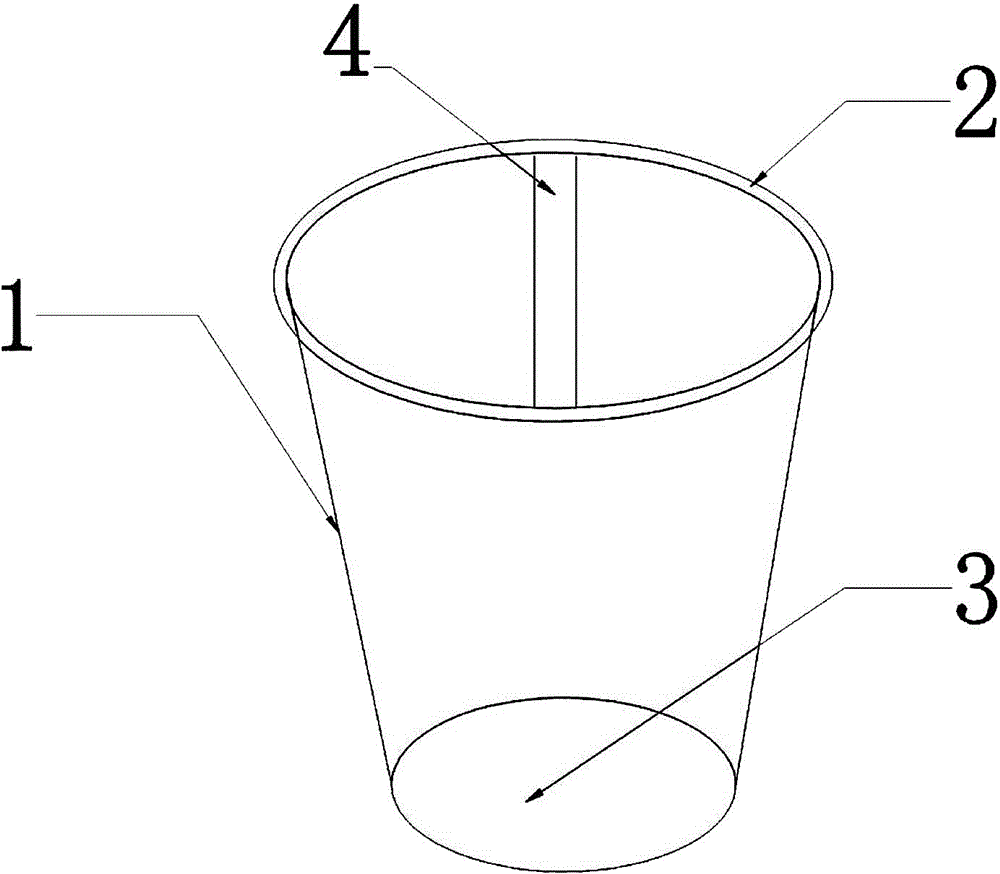

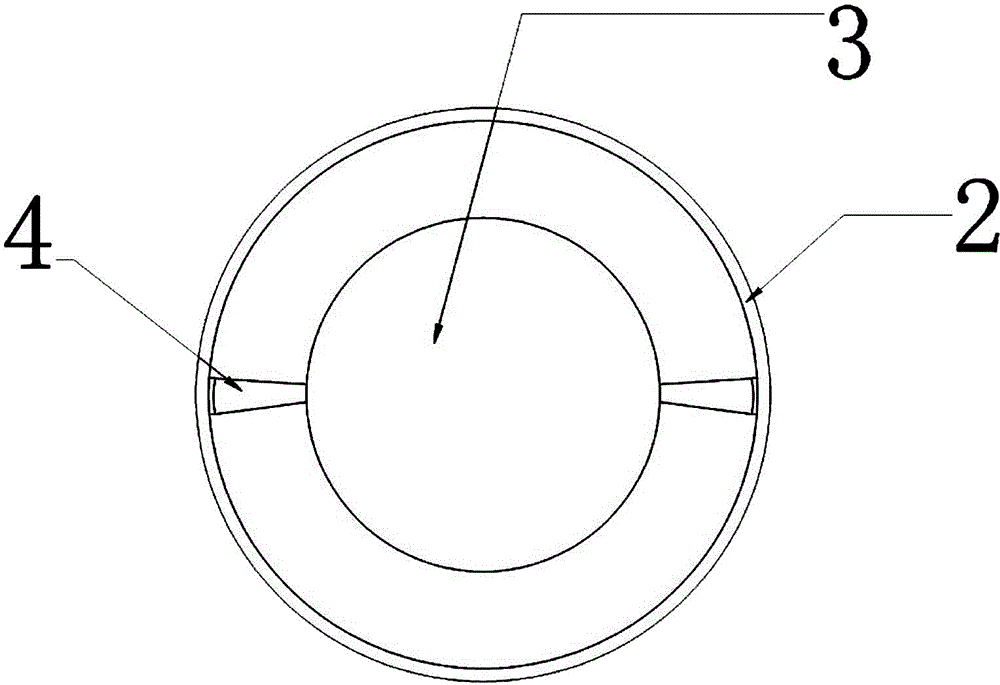

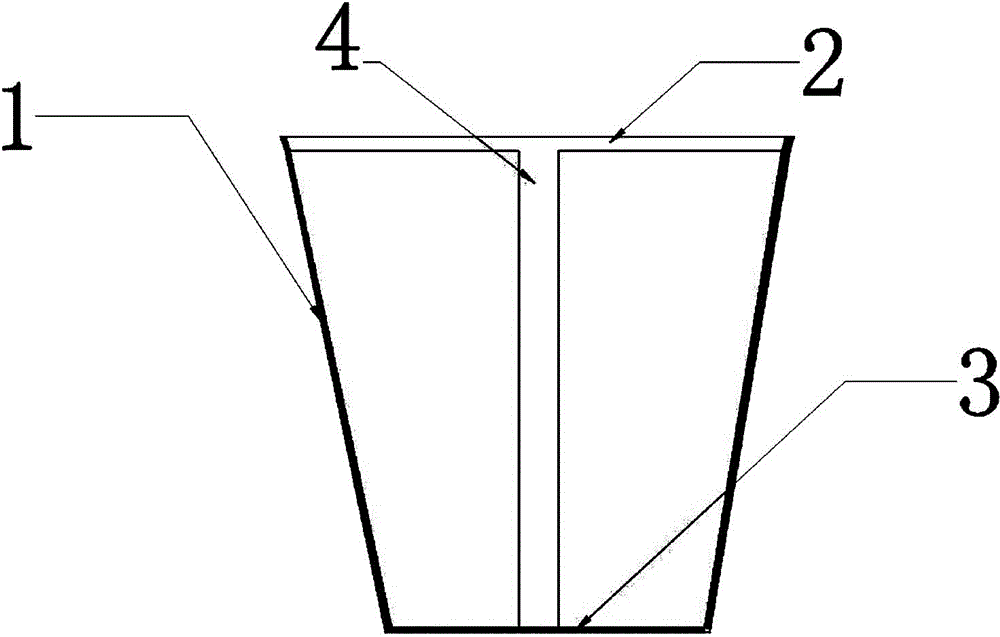

Manufacturing method of environment-friendly container with 3D color printing picture and environment-friendly container

ActiveCN103332352AEnhanced 3D effectImprove aestheticsCoverings/external coatingsRigid containersSheet filmColor printing

The invention relates to a manufacturing method of an environment-friendly container with a 3D color printing picture and the environment-friendly container. The method comprises the steps of printing, spraying, forming, reinforcing and demolding. According to the printing step, the picture is printed on one side of a transparent film with thermosensitive color-changing printing ink by means of twice overlapping printing at room temperature, wherein the transparent film is made of PP materials, PET materials, PVC materials and PS materials. According to the spraying step, coating liquid formed by heat-melting of materials which are used for manufacturing the transparent film is atomized and evenly sprayed onto the side, with the picture, of the transparent film by means of over 1.2 atmospheric pressure to form a protective layer from a position 20-30 cm away the transparent film. According to the forming step, the transparent film is coiled to form a cylindrical shape on a mold, an upper base is attached to the coiled transparent film, and then the container is fixed and formed. According to the reinforcing step, an opening injection molding ring is formed at the opening end of the container in an injection molding mode, and reinforcing ribs extending from the opening end to the bottom are formed on the inner wall of the container in an injection molding mode.

Owner:DONGGUAN MORNING LIGHT PRINTING

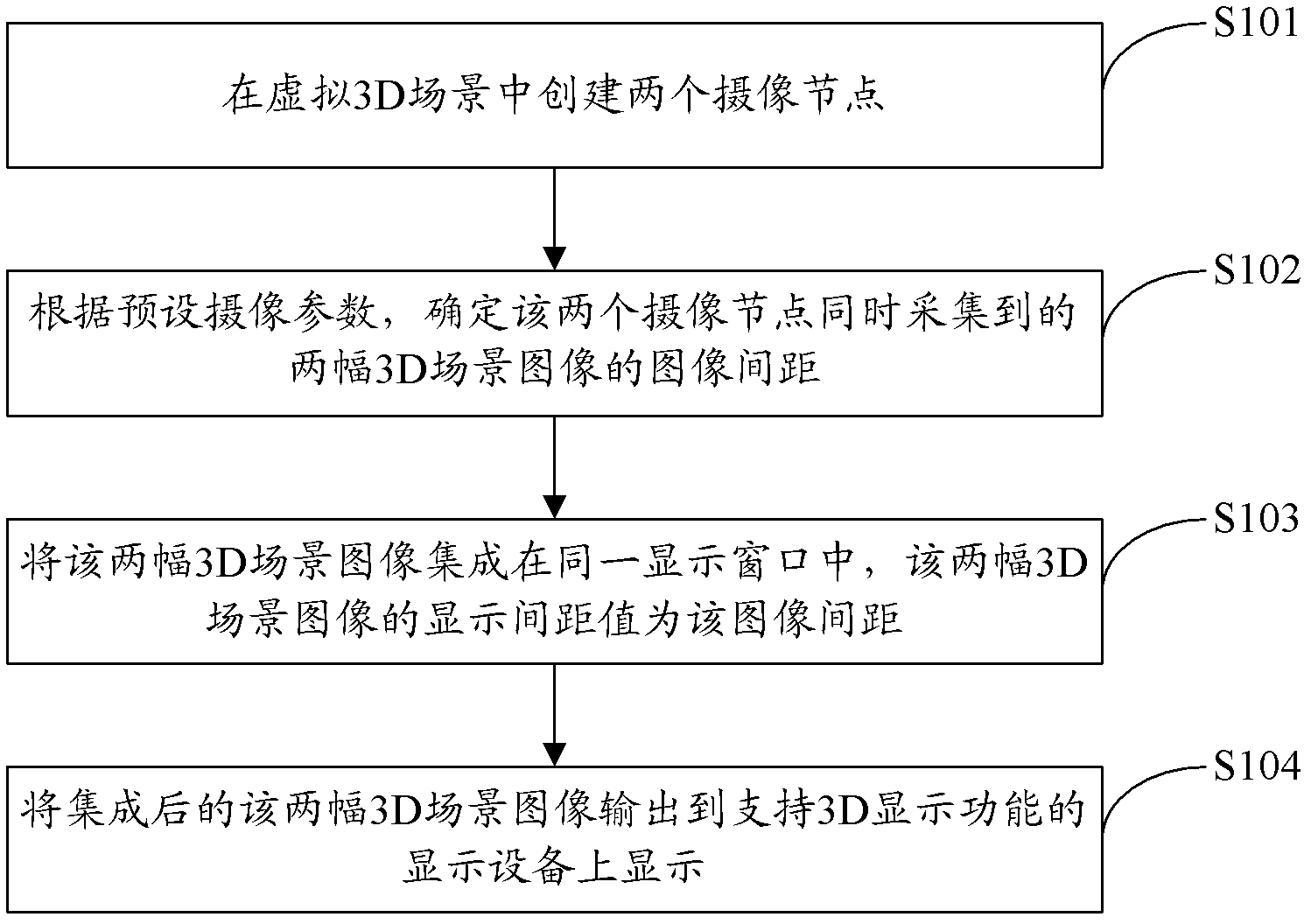

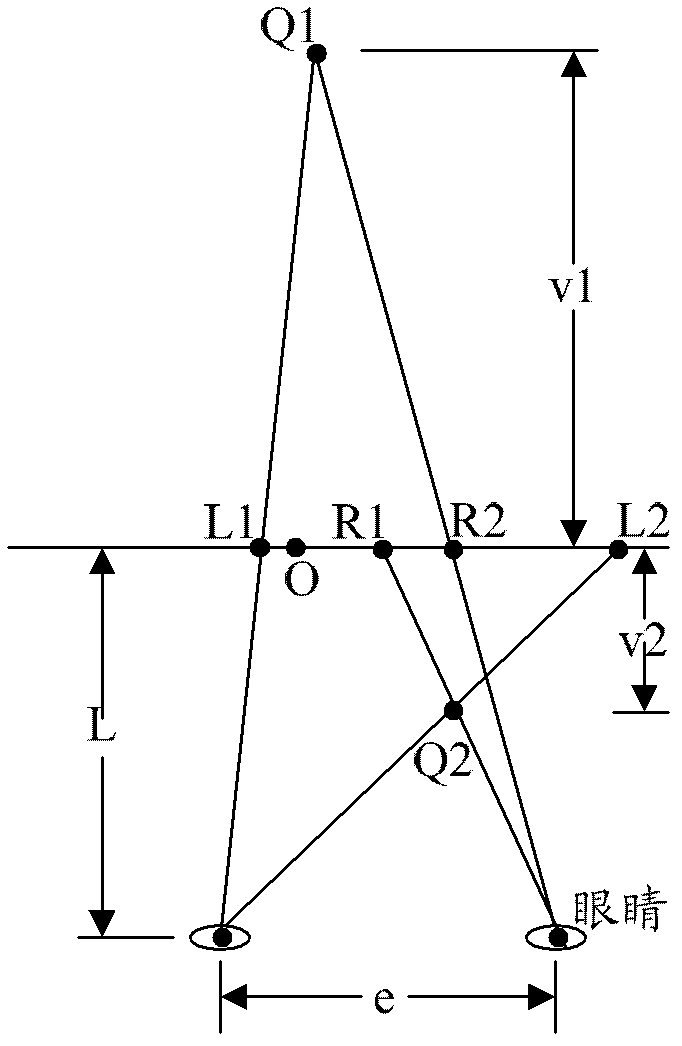

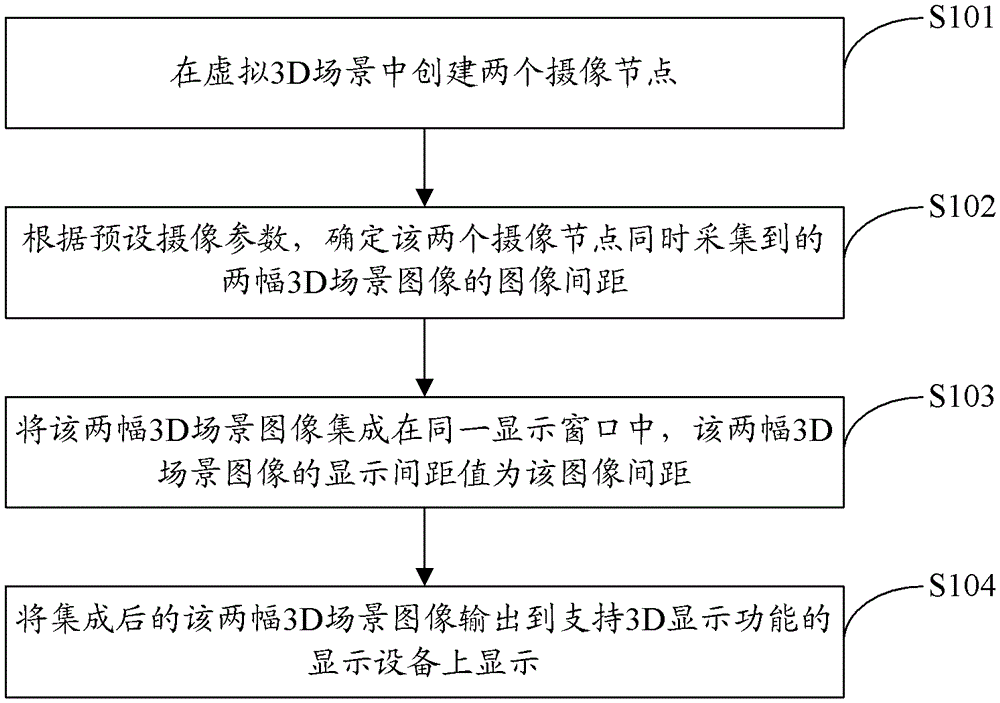

A 3D scene imaging method, device and display terminal

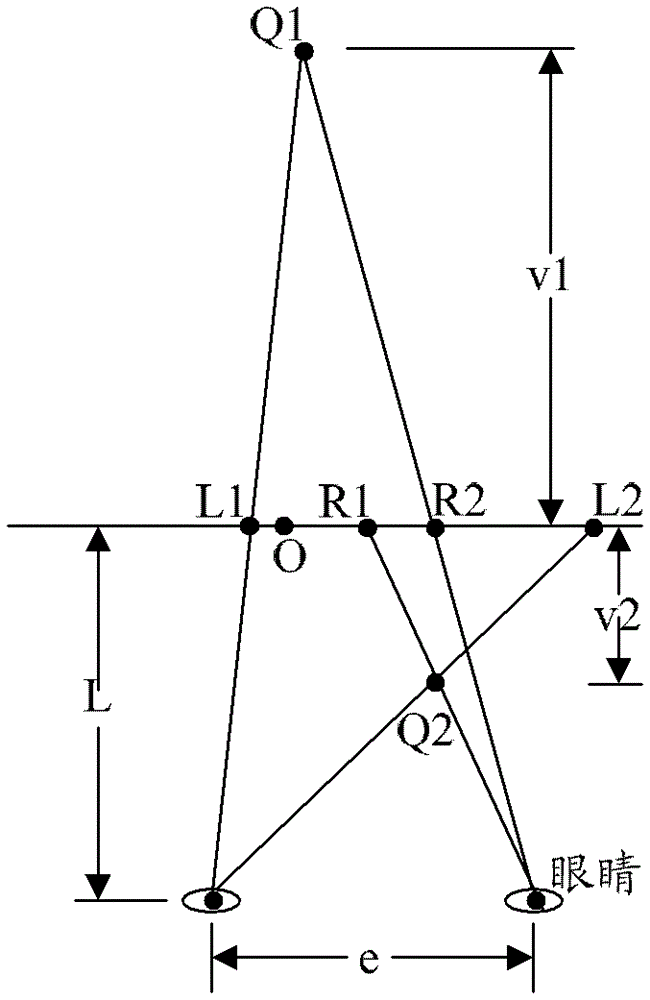

InactiveCN102662292BAccurate 3D effectEnhanced 3D effectPrintersProjectorsComputer graphics (images)Radiology

The present invention is applicable to the field of 3D display technology, and provides a 3D scene imaging method, device and display terminal. The method includes the following steps: creating two camera nodes in a virtual 3D scene; The image spacing of the two 3D scene images collected by the two camera nodes at the same time; the two 3D scene images are integrated in the same display window, and the display spacing value of the two 3D scene images is the image spacing; the integrated The two 3D scene images are output to a display device supporting a 3D display function for display. The invention improves the accuracy of 3D imaging and also enhances the 3D effect after imaging.

Owner:TCL CORPORATION

A multi-view glasses-free 3D display area compensation method based on lenticular grating

ActiveCN107801019BReduce distortionEnhanced 3D effectSteroscopic systemsOptical elementsGratingDisplay device

The invention relates to the field of naked eye 3D display, especially to a region compensation method of multi-view naked eye 3D display based on the cylindrical mirror grating. The region compensation method of the multi-view naked eye 3D display based on the cylindrical mirror grating comprises the following steps: dividing the screen into a plurality of regions according to the design parameter features of the naked eye 3D display device; and debugging each area as an independent sub-screen. The region compensation method of the multi-view naked eye 3D display based on the cylindrical mirror grating provided by the invention can reduce the deformation of the liquid crystal screen and the deformation of the grating, and can reduce the affect of the 3D effect caused by the unevenness generated by the lamination of the liquid crystal screen and the grating, therefore, the display effect of the naked eye 3D is improved.

Owner:广州大眼猫医疗器械科技有限公司

Rotating body material distribution mold and method for preparing artificial stone checkered plate by using same

ActiveCN112976599ASmooth transitionReduce labor intensityMouldsPress rollersElectric machinerySlurry

The invention relates to a concave-convex rotating body material distribution mold. The concave-convex rotating body material distribution mold comprises a hollow cylinder, grooves with gradually-changed depths are formed in the outer surface of the hollow cylinder in the circumferential direction, and small air holes communicating with the inside of the hollow cylinder are distributed in the grooves. A compressed air inlet is formed in one bottom surface of the hollow cylinder, arc-shaped material guiding plates are arranged on the outer side surface of the hollow cylinder at intervals, and powder and slurry spraying openings are formed in the material guiding plates. A multi-color material hopper is arranged above the hollow cylinder. A rotating shaft is arranged in the hollow cylinder in a penetrating mode and driven by a variable-speed motor. The invention further discloses a method for manufacturing an artificial plate. The artificial stone plate manufactured by adopting the technology provided by the invention is vivid in effect and high in operability, and can be widely applied to the technical field of artificial stone.

Owner:FOSHAN MONICA QUARTZ STONE CO LTD

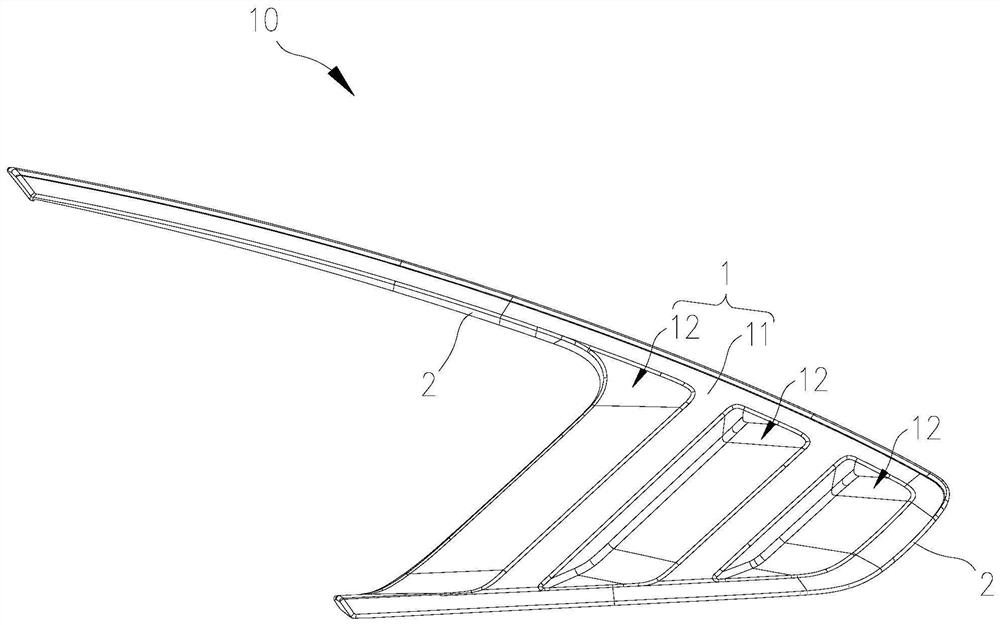

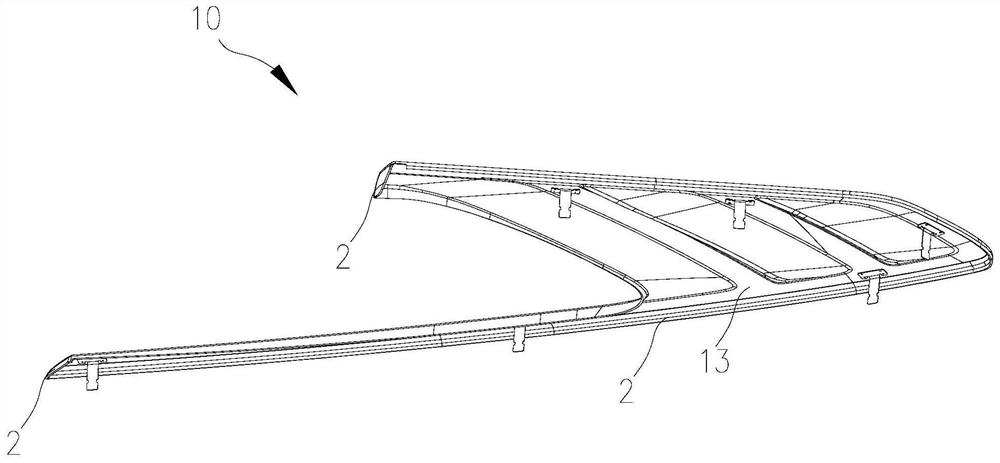

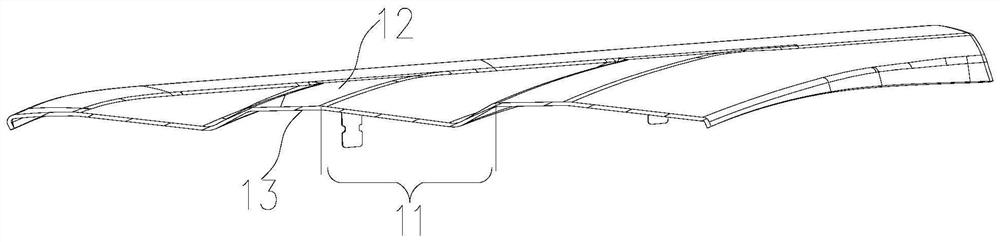

Aluminum alloy decorative part and its preparation method, vehicle body component

The invention provides a method for preparing an aluminum alloy decorative part. The aluminum alloy decorative part is used to decorate a car body. The method includes: forming an aluminum alloy base material, so that the aluminum alloy base material has a first surface; stamping the aluminum alloy base material For the aluminum alloy base material, a part of the first surface of the aluminum alloy base material is partially depressed to form at least one concave portion; and a bent edge is formed on the edge of the aluminum alloy base material. Surface gloss treatment and color treatment are performed on the first surface of the aluminum alloy substrate. The invention also provides an aluminum alloy decorative part and a vehicle body assembly. The preparation method of the aluminum alloy decorative part provided by the present invention can prepare the aluminum alloy decorative part with good appearance quality and diversity in appearance structure.

Owner:FUYAO GLASS IND GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com