Recyclable four-side elastic lace fabric with enhanced 3D effect and preparation method thereof

A 3D effect, elastic lace technology, applied in the direction of fabric surface trimming, heating/cooling fabric, knitting, etc., can solve the problems of increasing recycling cost, reducing recycling efficiency, increasing production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

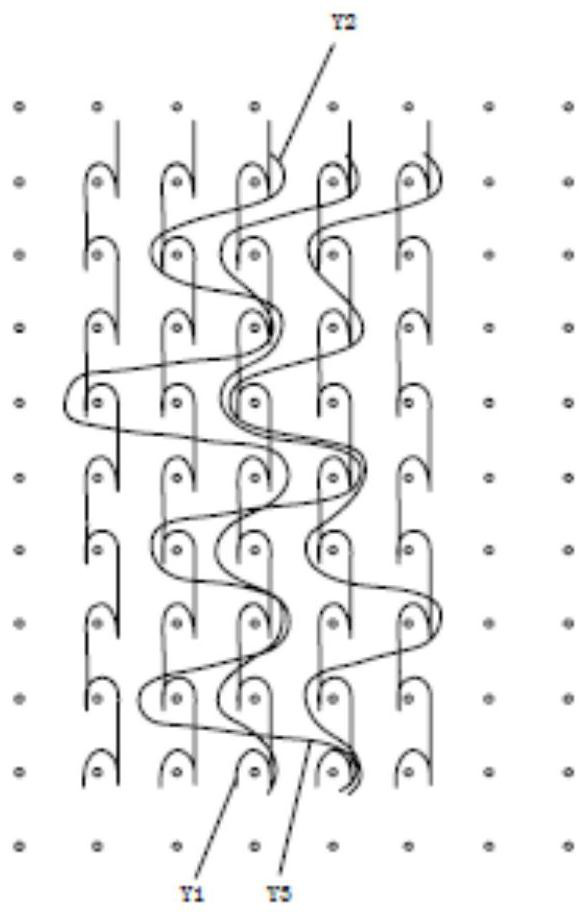

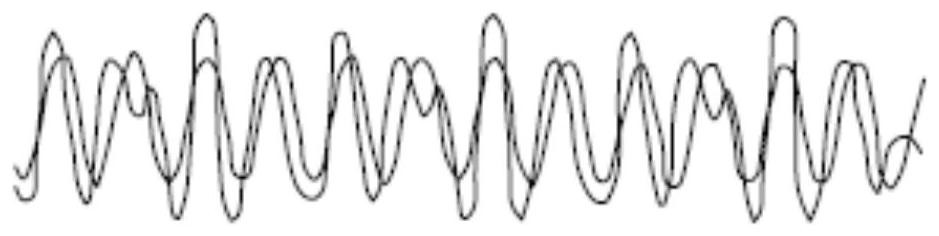

[0020] as attached Figure 1-4 As shown, the present invention discloses a recyclable four-way elastic lace fabric with enhanced 3D effect, including a fabric body, on which a pattern is formed by weaving, and the fabric body adopts yarn Y1, yarn Y2, and yarn Y3 Weaving with three kinds of yarns, among which yarns Y1 and Y2 are elastic composite yarns of the same material without spandex, and yarn Y3 is made of the same material as yarn Y1 and yarn Y2, and are elastic composite yarns without spandex 1. Single elastic yarn without spandex or non-elastic yarn, wherein yarn Y1 is woven in a knitting chain structure, yarn Y2 is woven in a weft-inserted jacquard structure, and yarn Y1 and yarn Y2 are woven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com