Aluminum alloy decorative part and its preparation method, vehicle body component

A technology for aluminum alloys and decorative parts, applied in vehicle parts, transportation and packaging, etc., can solve problems such as single surface structure and difficulty in meeting consumers' aesthetic needs, and achieve the effect of increasing 3D effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

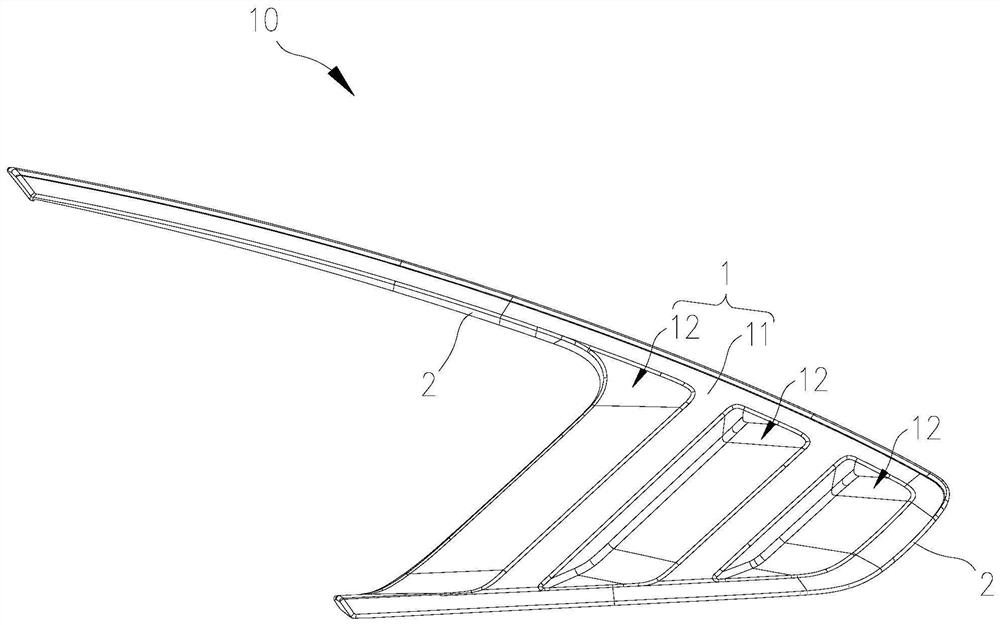

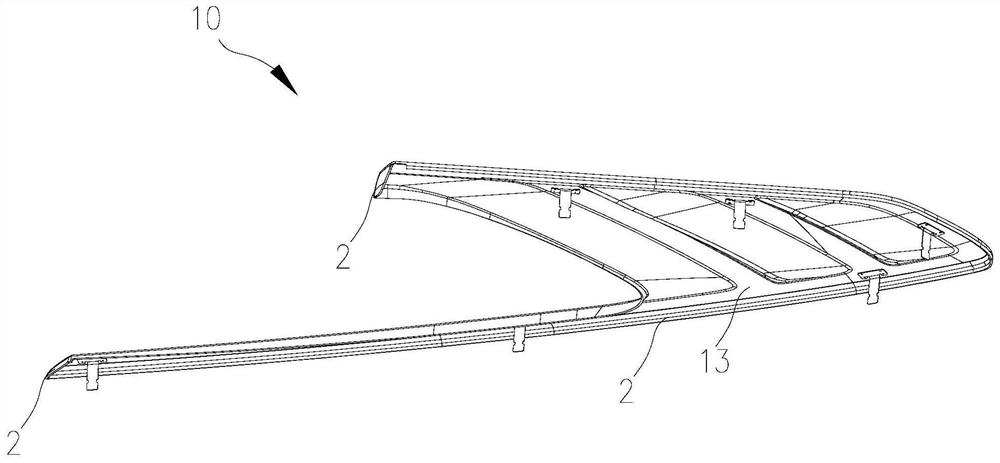

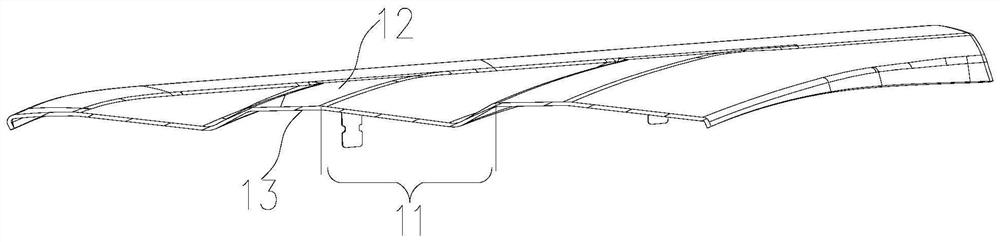

[0052] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. The embodiments listed in the present invention can be properly combined with each other.

[0053] The current automobile body components include glass, glass frame and aluminum alloy trim. Wherein, the glass frame surrounds the peripheral edge of the glass, and the material of the glass frame can be plastic or the like. The aluminum alloy decorative part can be connected to the glass frame by means of mechanical clamping, adhesive connection, etc., so that the aluminum alloy decorative part can decorate at least one side of the glass. In order to respond to the design requirements of uniform surface gloss, high surface smoothness, and good appearance of aluminum allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com