Manufacturing method for high-precision wood grain image

A technology of high-precision wood grain and production methods, applied in the direction of manufacturing tools, wood processing appliances, and techniques for producing decorative surface effects, etc., to achieve better layering and strong 3D effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

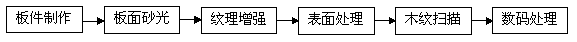

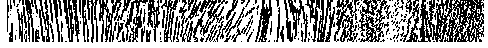

[0015] control figure 1 , a method for making a high-precision wood grain image, comprising the following process steps:

[0016] 1) Board production: according to the needs of the wood grain pattern, saw the string-cut board (mountain grain) or quarter-cut board (straight grain), and the board surface is planed and smooth;

[0017] 2) Sanding the surface of the board: choose different types of abrasive belts according to different types of wood, sand the surface of the board along the direction of the wood grain, and clean up the wood chips and dust in the pits on the surface of the wood;

[0018] 3) Texture enhancement: by painting water-based paint or color reagent (KMnO 4 Solution) makes the wood texture more prominent, which is convenient for subsequent scanning imaging;

[0019] 4) Surface treatment: Polish the surface of the panel after the texture enhancement treatment, remove the wood wool caused by contact with the solution, and then apply a low-gloss paint once, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com