Loading platform for chemical tank wagon

A loading and unloading platform and chemical technology, applied in the chemical industry, can solve problems such as inconvenient operation, complicated operation, chemical pollution, etc., and achieve the effects of small external climate impact, high safety performance, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

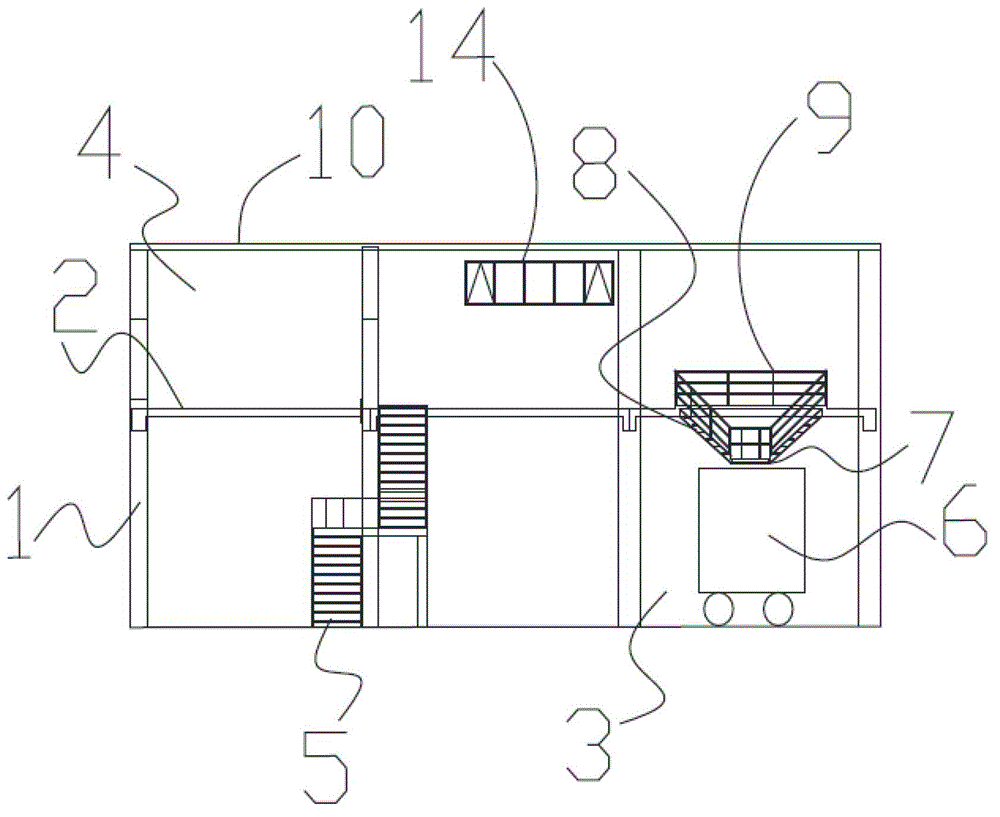

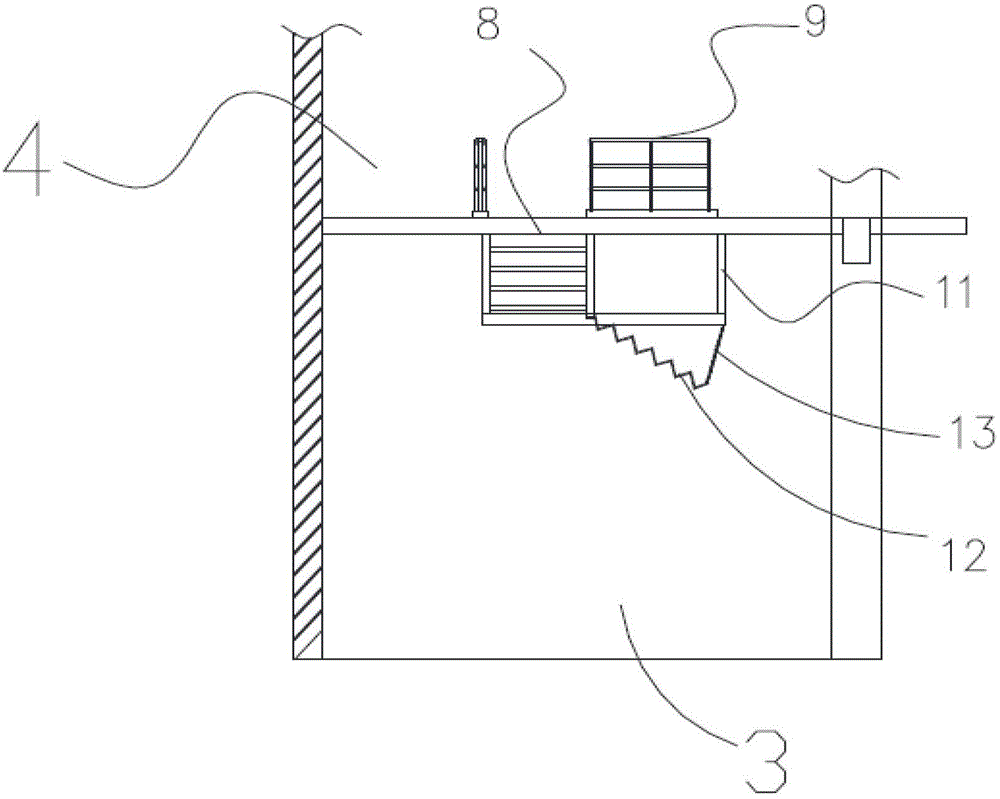

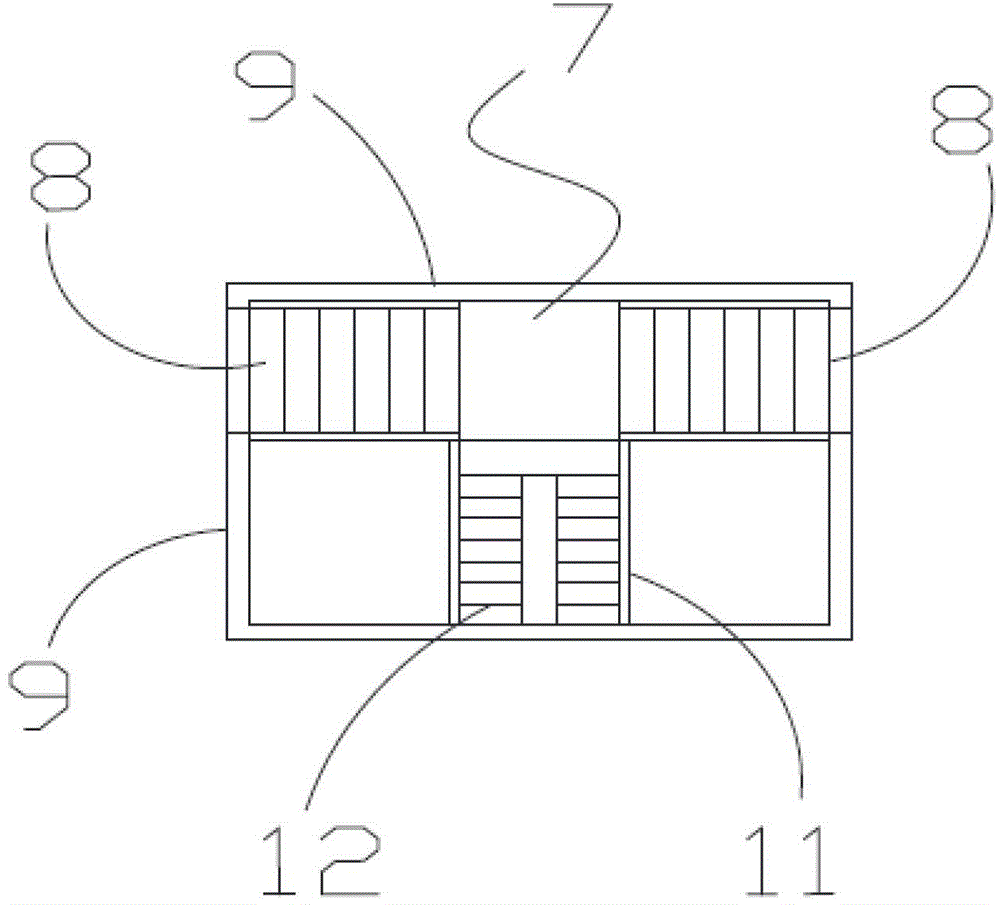

[0020] Such as figure 1 , shown in 2 and 3, a chemical tanker loading and unloading platform, the loading and unloading platform includes an open bottom 3 for parking the tanker 6, a docking layer 4 above the bottom 3, the bottom 2 and the docking layer 4 Stairs 5 are arranged between them, and a lapping platform 7 is hoisted on the top of the bottom layer 3, and the lapping platform communicates with the docking layer, and the lapping platform 7 is connected to the docking layer 4 through a fixed short ladder 8. Fixedly connected, the height of the overlapping platform 7 from the bottom surface of the bottom layer 3 is greater than the height of the tank car 6, and the overlapping platform 7 is provided with a soft ladder 12 for connecting with the top platform of the tank car 6. One end of the soft ladder 12 is connected with the connecting platform 7, and the other end of the soft ladder 12 is connected with the fixed mount 11 arranged on one side of the connecting platform...

Embodiment 2

[0022] On the basis of Embodiment 1, the preferred technical solution of the present invention also includes that the soft ladder 12 is fixed at the end of the overlapping platform 7 by bolts or hinges.

Embodiment 3

[0024] On the basis of Embodiment 1, the preferred technical solution of the present invention further includes that the two ends of the overlapping platform 7 are respectively provided with short fixed ladders 8 communicating with the docking layer 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com