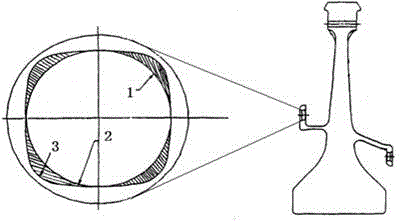

Multi-arc specially-shaped hole

A technology of special-shaped holes and arcs, which is applied in the direction of supporting elements of blades, engine elements, machines/engines, etc., to achieve the effect of improving service life and reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

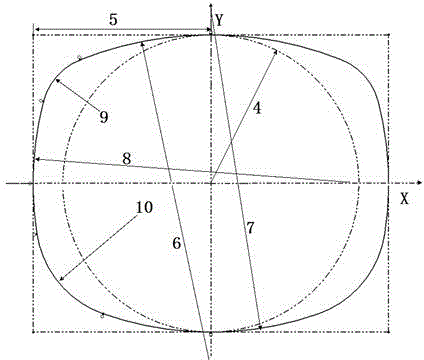

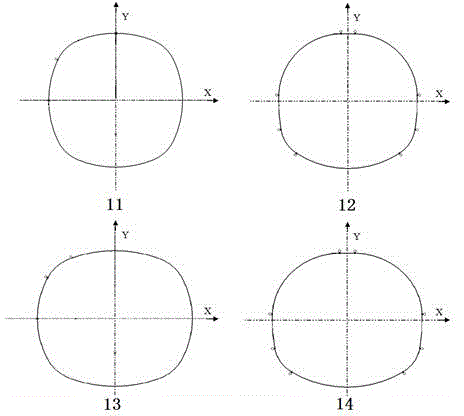

[0043] Please refer to figure 2As shown, the diameter of the circular bolt hole before improvement is defined as a . The maximum longitudinal profile of the special-shaped hole profile is a, the maximum transverse profile is b, and a≤b is required. The geometric profile of multi-arc shaped holes is composed of eight smooth and tangent arcs. It is stipulated that the contour of the hole is symmetrical about the Y axis, and the eight arcs are respectively a top main arc R1 (R1 is the radius), a bottom main arc R2 (R2 is the radius), and two side main circles that are symmetrical about the Y axis Arc R3 (R3 is the radius), two upper transition arcs R4 (R4 is the radius) symmetrical about the Y axis, and two lower transition arcs R5 (R5 is the radius) symmetrical about the Y axis.

[0044] figure 2 The outline of the middle dotted line is the outline of the base circle in the original design, and the outline of the eight-segment arc shaped hole is determined by a total of 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com