All-region heat-pump horizontal shell-and-tube heat exchanger

A shell-and-tube heat exchanger, heat pump type technology, used in evaporators/condensers, lighting and heating equipment, refrigeration components, etc. Heat pipe cleaning is difficult and other problems, to achieve the effects of excellent corrosion resistance, sufficient oil return, and improved heat exchange performance and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further elaborated below in conjunction with the accompanying drawings.

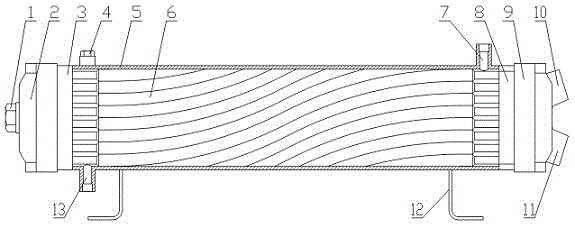

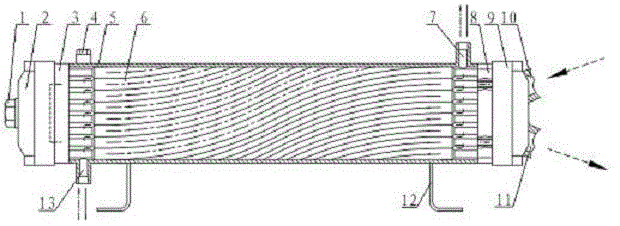

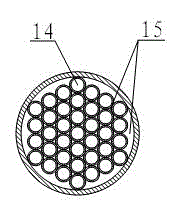

[0018] Such as figure 1 An all-area heat pump horizontal shell-and-tube heat exchanger is shown, which includes anti-corrosion zinc block 1, cover head, composite tube sheet, fusible plug 4, cylinder body 5, heat exchanger 6, refrigerant inlet 7, refrigeration Agent outlet 13, cooling water inlet 10, cooling water outlet 11 and foot 12, the left end of the cylinder body 5 is provided with a composite tube sheet I3, and the cap I2 is connected to the composite tube sheet I3, and the right end is provided with a composite tube sheet Ⅱ8, connected with the composite tube sheet Ⅱ8 is the cap Ⅱ9, the cylinder 5 is provided with a fusible plug 4 above the left end, a refrigerant outlet 13 below, a refrigerant inlet 7 above the right end, and a pair of bottoms at the lower end Feet 12, with a number of heat exchange tubes 6 inside, which are tightly arranged and arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com