Preparation method of amorphous silicon dioxide ceramic coated polyester fiber oil absorption material

A polyester fiber and oil-absorbing material technology, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve the problems of low oil absorption rate and oil retention rate, poor oil-water selectivity, etc., and achieve good oil absorption and oil retention performance , stable chemical properties, excellent adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

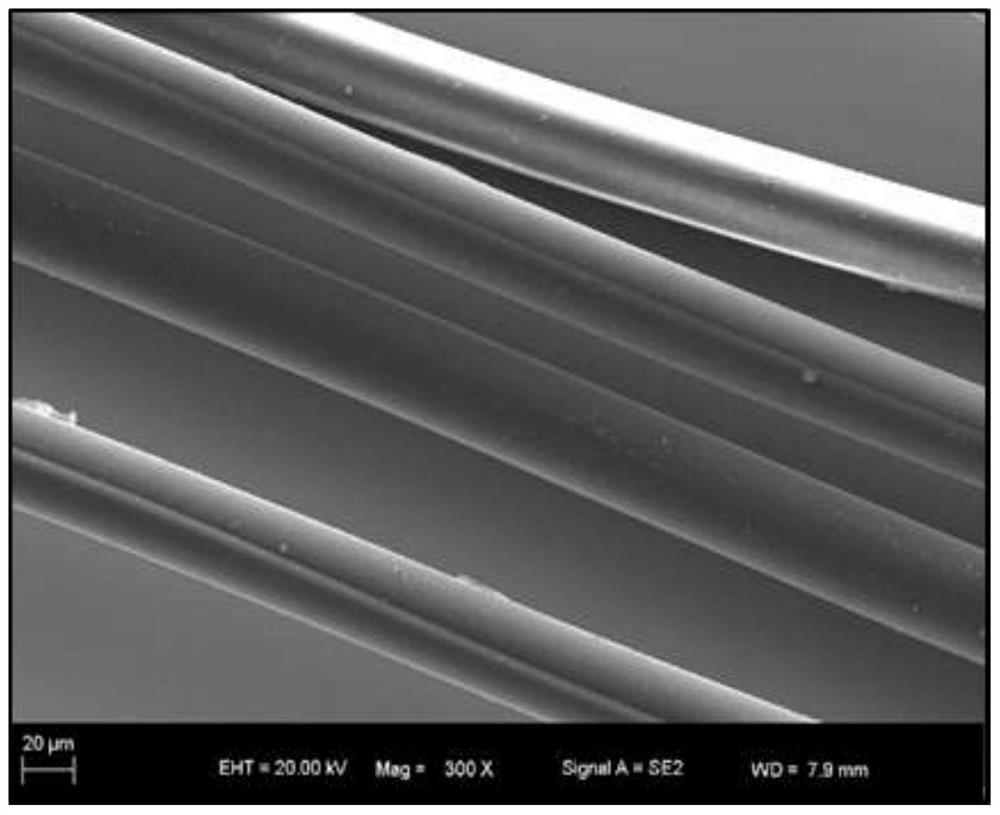

[0039] Step 1, impregnation of polyester fibers into SiO 2 10s in the sol, take it out, and dry it at 25°C for 2h to get SiO 2 Polyester fiber for gel coat;

[0040] Among them, SiO 2 The preparation process of the sol is as follows: at room temperature, add ethyl orthosilicate to the mixture of absolute ethanol and deionized water, then add acetic acid drop by drop, and stir magnetically for 8 hours to obtain SiO 2 Sol;

[0041] Among them, SiO 2 The concentration of the sol is 0.2mol / L, absolute ethanol is the solvent, and the molar ratio of ethyl orthosilicate, deionized water, and acetic acid is 1:6:0.08;

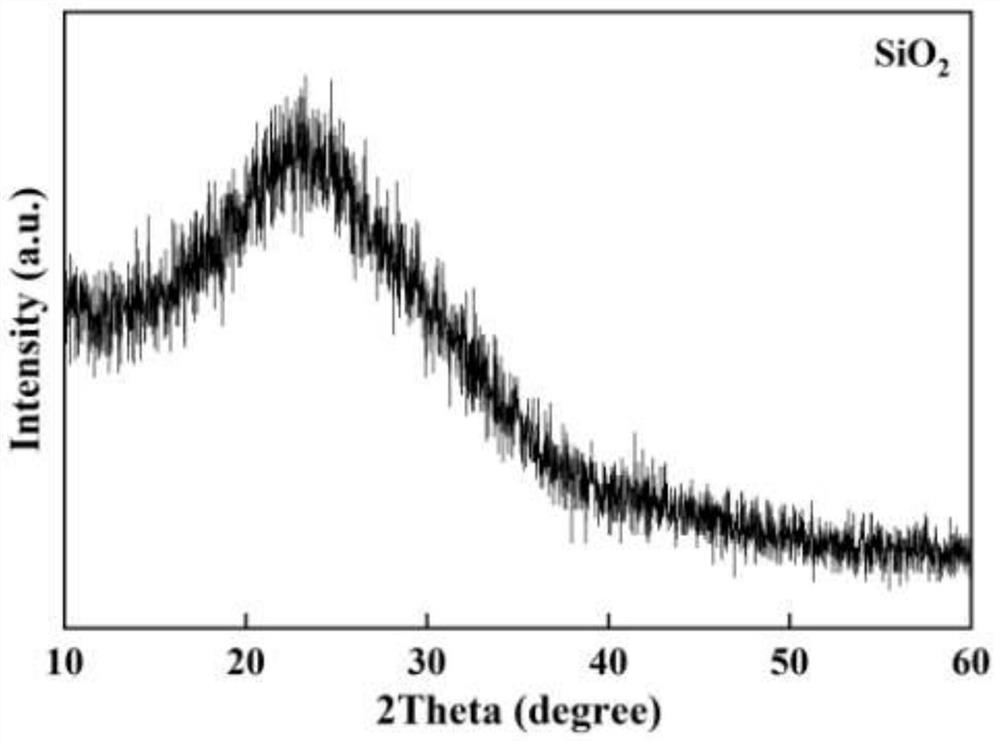

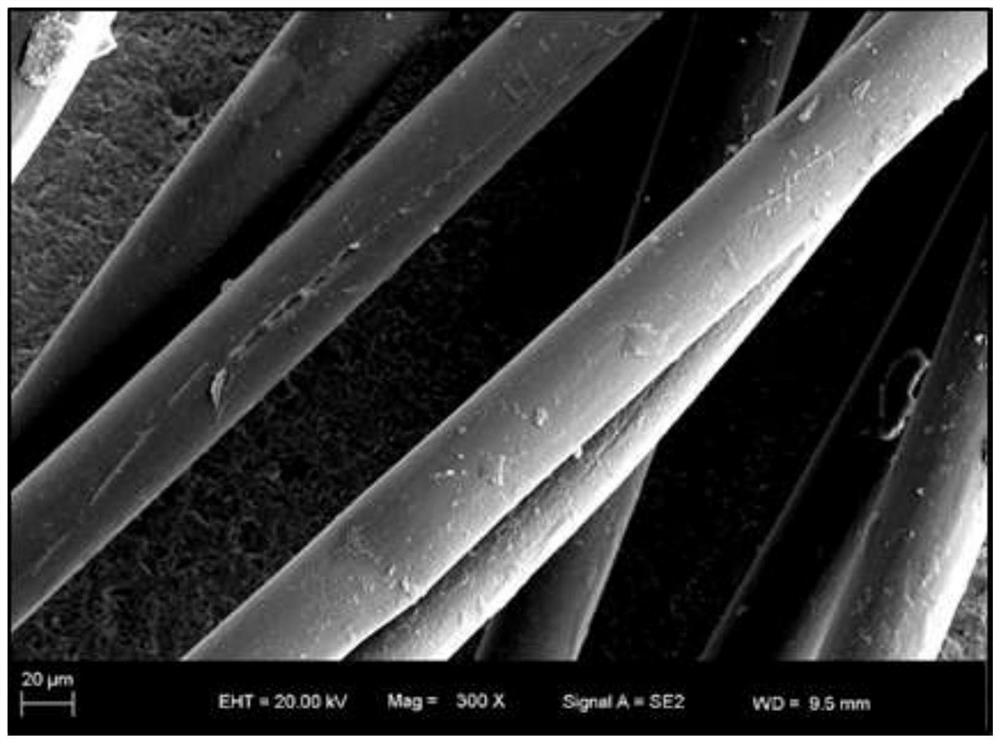

[0042] Step 2, with SiO obtained in step 1 2 Gel-coated polyester fibers converted to amorphous SiO by UV-assisted low-temperature heat treatment 2 Polyester fiber coated with ceramic layer;

[0043] Among them, the wavelength of ultraviolet light is 180nm, the irradiation time is 0.5h, and the auxiliary heating temperature is 100°C;

[0044] Step 3, the amorpho...

Embodiment 2

[0057] Step 1, impregnation of polyester fibers into SiO 2 10s in the sol, take it out, and dry it for 1.5h at a temperature of 40°C in the room to obtain a SiO 2 Polyester fiber for gel coat;

[0058] Among them, SiO 2 The preparation process of the sol is as follows: at room temperature, add tetraethyl orthosilicate to the mixture of absolute ethanol and deionized water, then add acetic acid drop by drop, and magnetically stir for 10 hours to obtain SiO 2 Sol;

[0059] Among them, SiO 2 The concentration of the sol is 0.5mol / L, absolute ethanol is the solvent, and the molar ratio of ethyl orthosilicate, deionized water, and acetic acid is 1:6:0.08;

[0060] Step 2, with SiO obtained in step 1 2 Gel-coated polyester fibers converted to amorphous SiO by UV-assisted low-temperature heat treatment 2 Polyester fiber coated with ceramic layer;

[0061] Among them, the wavelength of ultraviolet light is 200nm, the irradiation time is 1.5h, and the auxiliary heating temperatu...

Embodiment 3

[0071] Step 1, impregnation of polyester fibers into SiO 2 sol for 10s, take it out, and dry it at 60°C for 1h to obtain SiO 2 Polyester fiber for gel coat;

[0072] Among them, SiO 2 The preparation process of the sol is as follows: at room temperature, add ethyl orthosilicate to the mixture of absolute ethanol and deionized water, then add acetic acid drop by drop, and stir magnetically for 12 hours to obtain SiO 2 Sol;

[0073] Among them, SiO 2 The concentration of the sol is 0.8mol / L, absolute ethanol is the solvent, and the molar ratio of ethyl orthosilicate, deionized water, and acetic acid is 1:6:0.08;

[0074] Step 2, with SiO obtained in step 1 2 Gel-coated polyester fibers converted to amorphous SiO by UV-assisted low-temperature heat treatment 2 Polyester fiber coated with ceramic layer;

[0075] Among them, the wavelength of ultraviolet light is 237nm, the irradiation time is 2h, and the auxiliary heating temperature is 150°C;

[0076] Step 3, the amorphou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com