Field sampling device special for transformer insulating oil

A transformer insulating oil and on-site sampling technology, applied in the direction of sampling devices, etc., can solve the problems of glass syringes falling off, damaged, sample preparation failure, etc., to avoid air contact and quantitative errors, overcome fragility and fragility, and reduce errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings. It should be emphasized that the embodiments of the present invention are illustrative rather than restrictive, so the present invention is not limited to the implementation described in the specific embodiments. For example, all other implementations obtained by those skilled in the art according to the technical solution of the present invention also belong to the protection scope of the present invention.

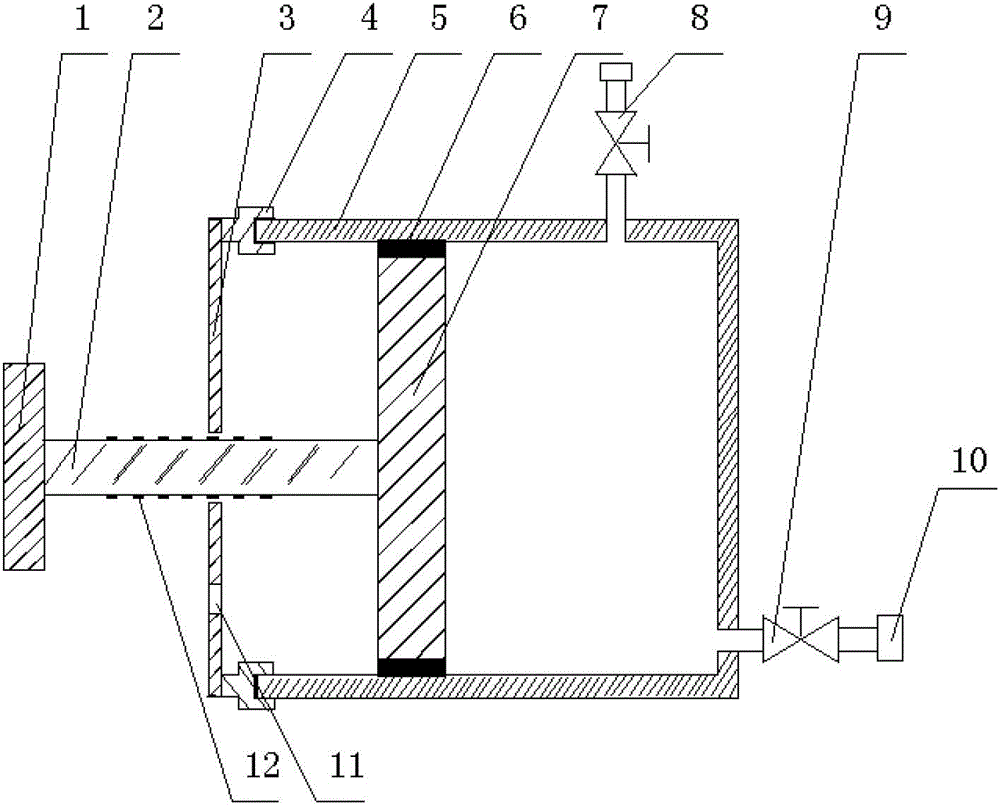

[0019] A field sampling device dedicated to transformer insulating oil, such as figure 1 As shown, it includes a core plug 2, a circular cover 3 with a central hole set on the core plug, and a circular cylinder 5 fitted with the circular cover, and a cylindrical core is screwed on the left end of the core plug. Plug handle 1, the right end of the plug plug is fixed with a plug plug head 7 matching the inner diameter of the circular cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com