Vacuum on-load tap changer

A technology of on-load tapping and vacuum, which is applied in the direction of transformers, electrical components, variable inductors, etc., can solve the problems of reduced rigidity of insulating blocks, large impact of fixed contacts, and large vibration, so as to reduce gear costs and reduce Sports impact, good effect of self-locking function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

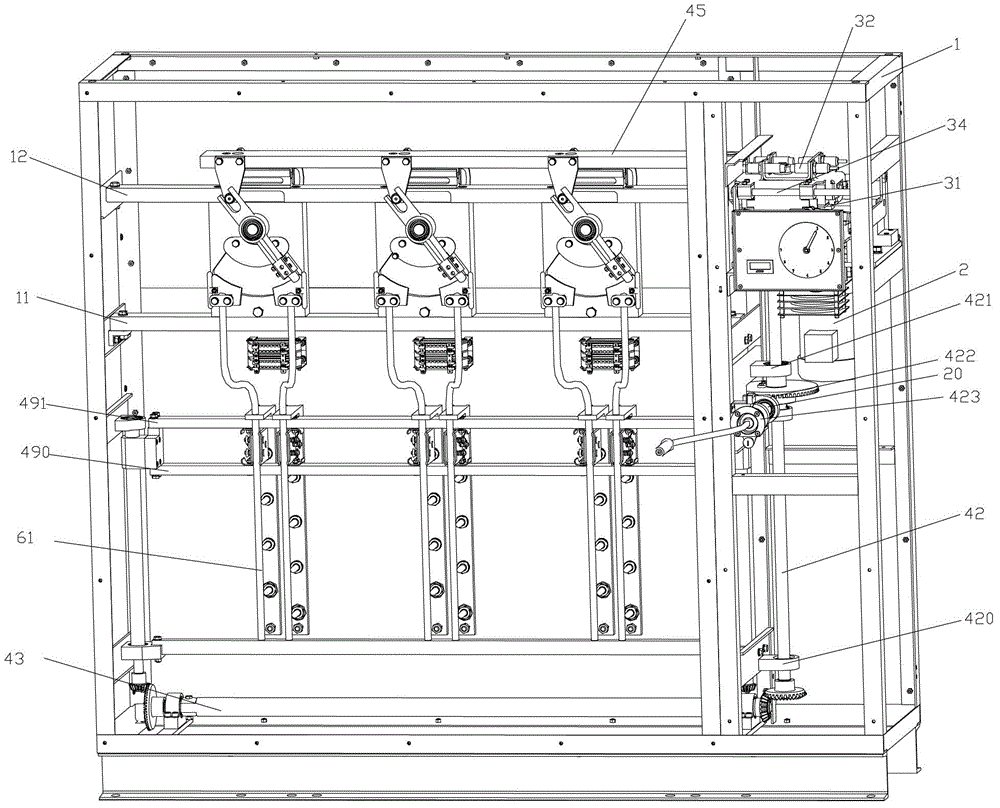

[0040] Such as figure 1 As shown, the vacuum on-load tap-changer described in this embodiment mainly includes the following four parts: (1) frame; (2) power drive mechanism; (3) vacuum bubble switching mechanism; (4) transformer winding tap position Adjustment device. The above four parts are described in detail below.

[0041] The first is the rack section, such as figure 1 As shown, the above-mentioned mechanisms and devices are all arranged in the frame 1, and the frame 1 is provided with two beams 11, 12 up and down. Three insulating blocks are evenly distributed between the two crossbeams to form a fixed frame of the switching mechanism. Specifically, two vacuum bubbles are installed on the rear side of each insulating block, arranged side by side. combine Figure 7 , There is an insulating bottom plate on the back of the rack, on which are installed 3 sets of vertical fixed contact mounting frames, each group of fixed contact mounting frames is composed of two insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com