Rotary wave energy piezoelectric power generation apparatus

A piezoelectric power generation and wave energy technology, which is applied in the direction of ocean energy power generation, generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, etc. Low frequency and other problems, to achieve the effect of wide response frequency and high power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

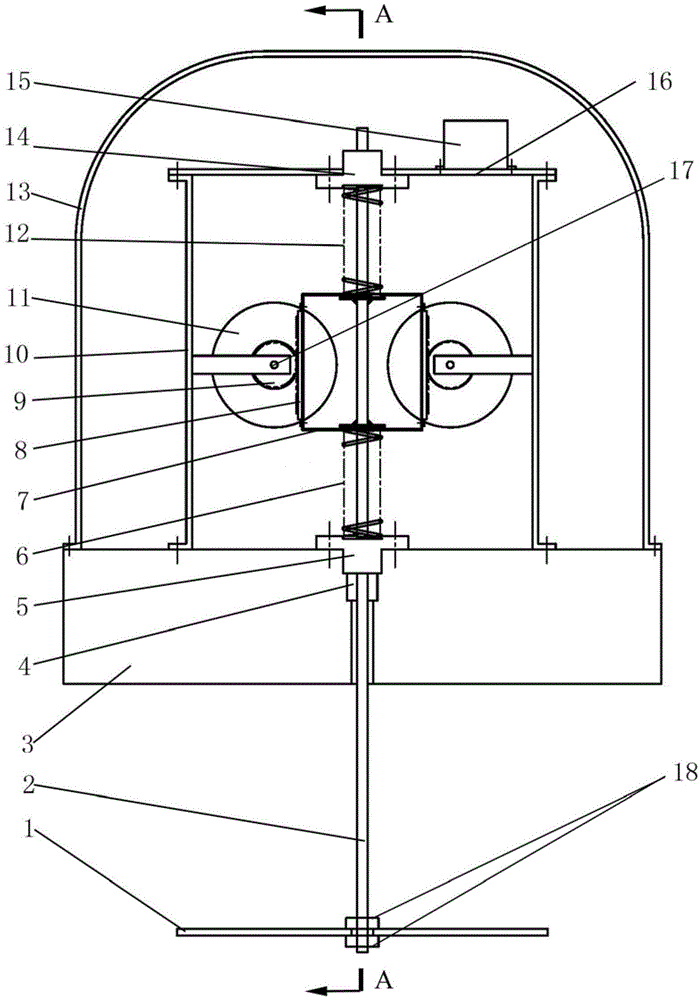

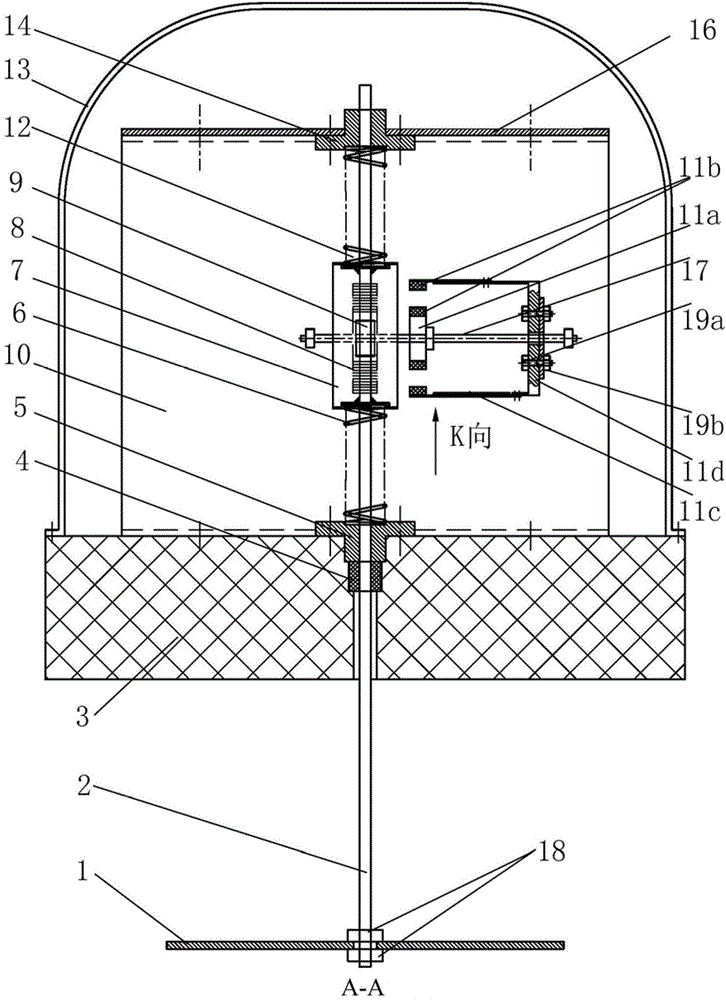

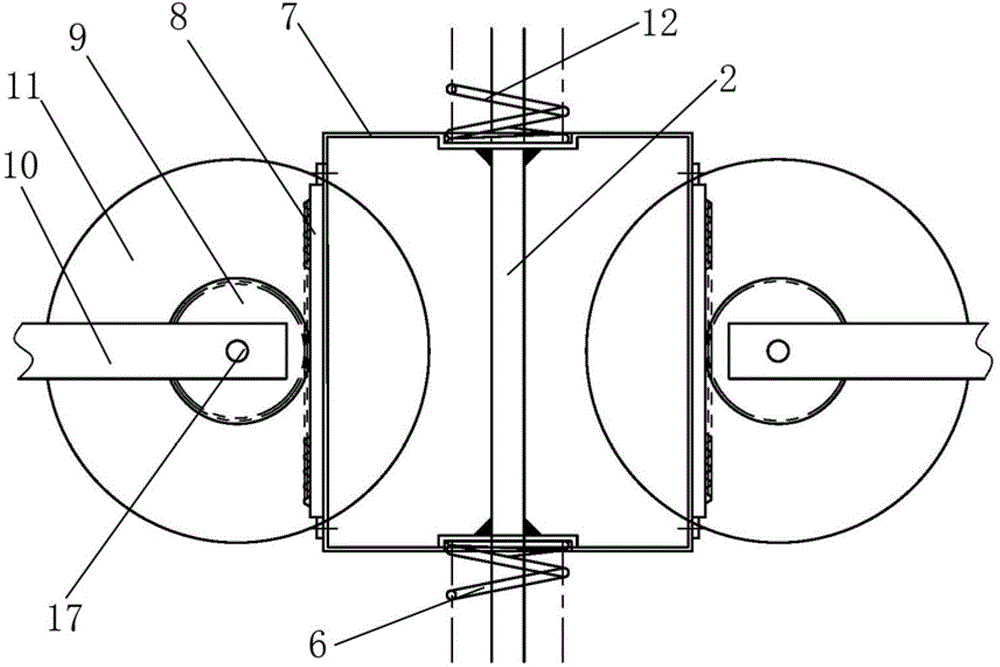

[0021]The specific implementation manner of the present invention will be described in detail in conjunction with the accompanying drawings and technical solutions. The invention relates to a wave energy rotary piezoelectric power generation device, which is composed of a primary energy conversion component, an intermediate conversion component, a secondary energy conversion component and a sealing assembly. The basic working principle is to convert the wave energy into linear mechanical energy by using the first-level transducing components; convert the linear mechanical energy into rotational mechanical energy by using the intermediate conversion components, and convert the rotational mechanical energy into electrical energy by using the secondary conversion components.

[0022] attached figure 1 A schematic diagram showing the structure of a wave energy rotary piezoelectric generator. Refer to attached figure 1 And attached figure 2 , In this embodiment, the end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com