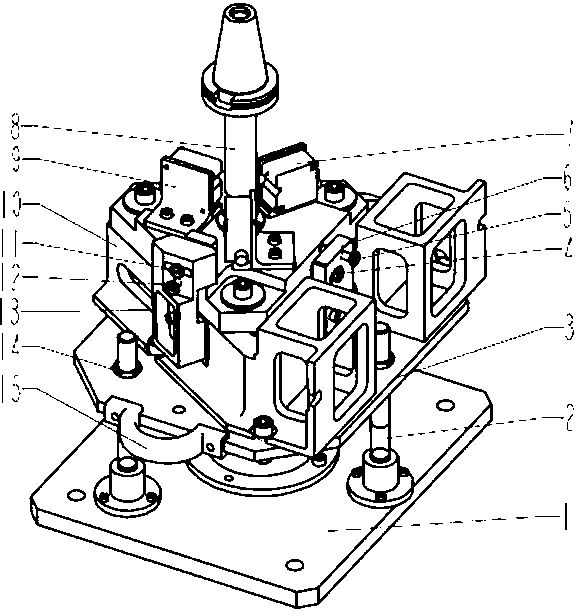

Sensor position adjusting device for spindle rotation error detection

A technology of rotation error and adjustment device, which is used in measuring/indicating equipment, metal processing mechanical parts, metal processing equipment, etc., can solve the problems of difficult to guarantee test accuracy and low test efficiency, and achieve the effect of light weight and accurate position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

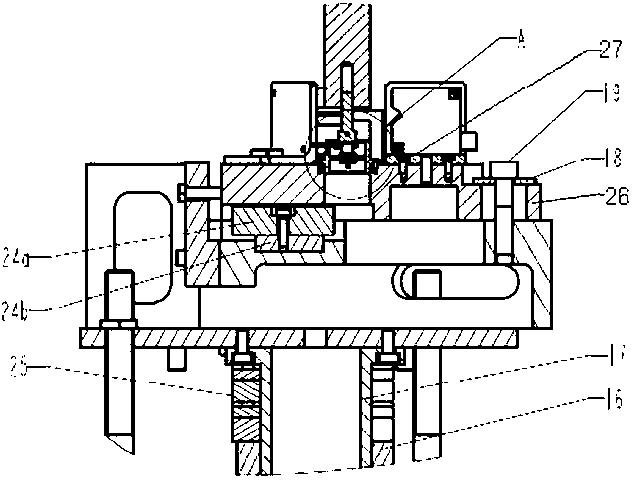

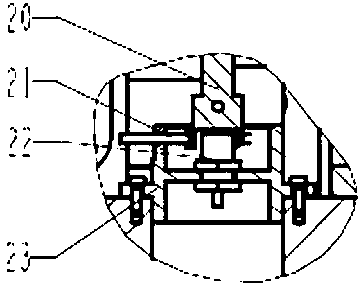

[0021] The invention will be further described below in conjunction with the accompanying drawings. The base 1 is the installation basis of the adjustment device. During the application process, the device is fixed to the test site through the base 1 . The base 1 is equipped with a guide sleeve 16, the guide sleeve 16 and the guide rod 17 fixed on the lifting plate 3 form a sliding pair, the axis of the sliding pair is perpendicular to the horizontal plane; handles 15 are fixed on both sides of the lifting plate 3; Driven by the drive, the height of the lifting plate 3 can be adjusted freely, and a group of “U” shaped spacers 25 with appropriate height can be inserted into the guide rod 17 to support the lifting plate 3 on the guide sleeve 16. One end of the compression screw 2 is fixed on the base 1, and the other end passes through the lifting plate 3, and the lifting plate is compressed by the nut 14. The quantity of compression screw rod 2 and nut 14 can be selected accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com