Connecting structure for glass plate and wire rope of cable mesh point-supported glass curtain wall

A glass curtain wall and connection structure technology, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of missing embedded parts, poor lighting effect, and many wall structures, so as to improve the connection fastness and facilitate Good installation and overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

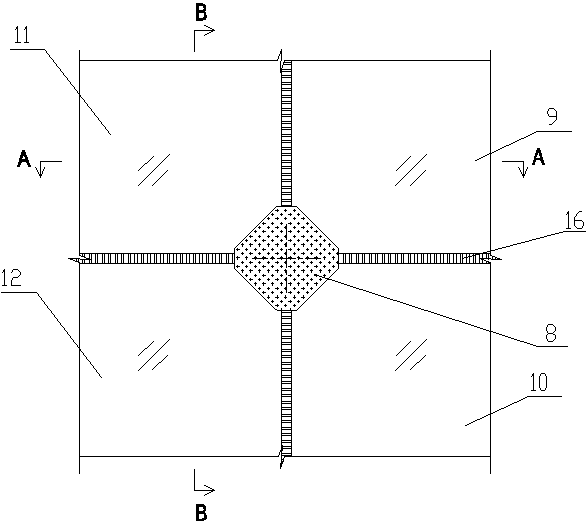

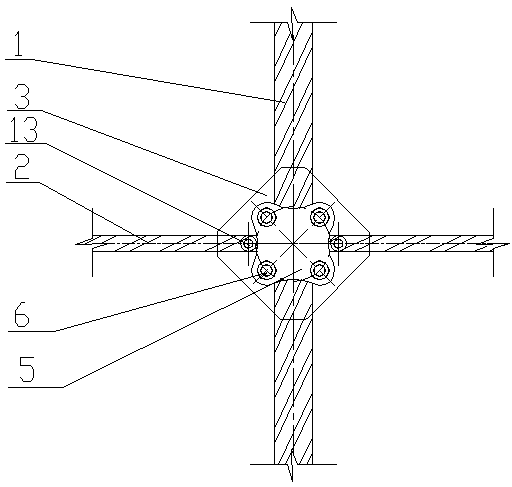

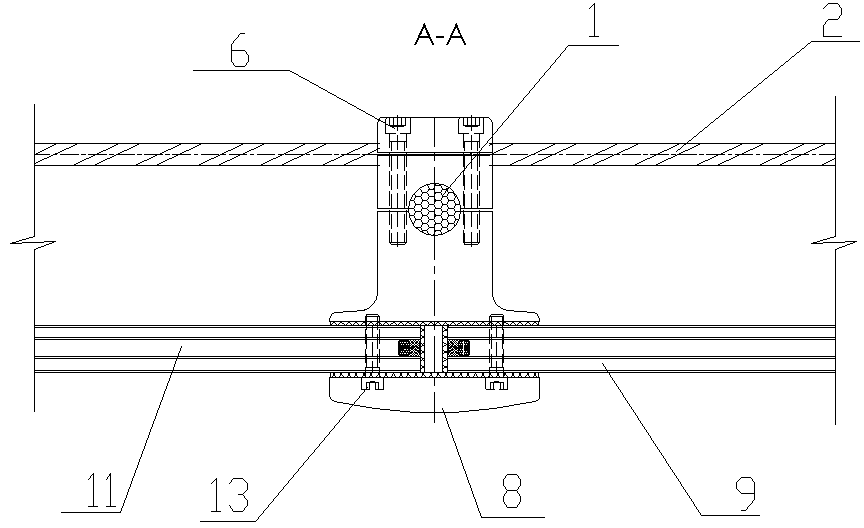

[0021] Such as figure 1 , 2 , 3, and 4, the present invention includes a first rope 1 and a second rope 2 that cross in a cross shape, the first splint 3 and the second splint 4 are respectively arranged on the front and rear sides of the first rope 1, and the second rope 2 It is arranged on the outside of the second splint 4 , and a stainless steel clamp 5 is arranged on the other side of the second rope 2 .

[0022] Four countersunk bolt holes are set on the first clamping plate 3, four through holes are set on the second clamping plate 4, four bolt holes are set on the stainless steel fixture 5, and the outside of each bolt is set on the countersunk head bolt of the first clamping plate In the hole, the middle part of the bolt is placed in the through hole of the second clamping plate corresponding to the countersunk bolt hole, and the internal thread of the bolt 6 is connected in the bolt hole of the stainless steel fixture 5 corresponding to the countersunk bolt hole. F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com