Multifunctional semiconductor sample fixture

A semiconductor and multi-functional technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of the absence of tiny samples of semiconductor devices, and achieve the effects of avoiding tilt, reducing damage, and avoiding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

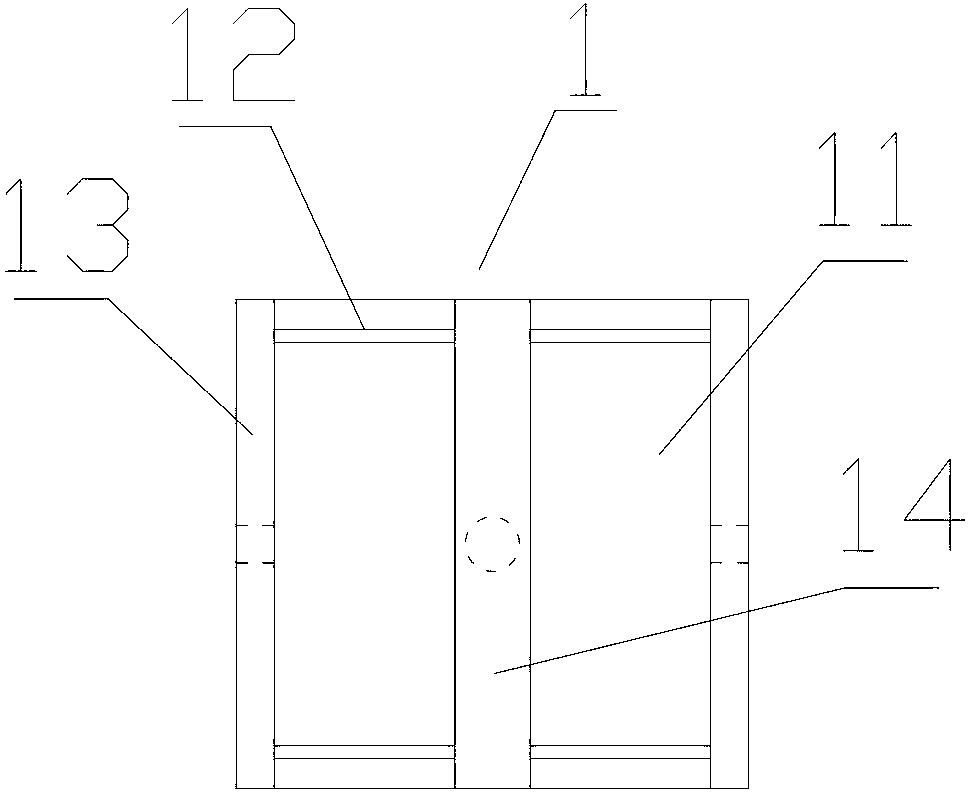

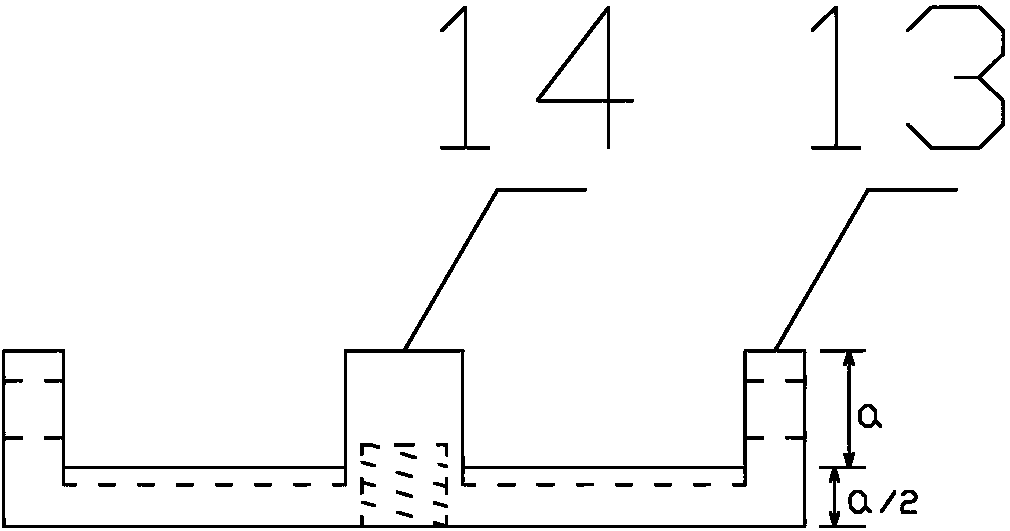

[0044] The invention is a multifunctional semiconductor sample fixture, more specifically a multifunctional fixture used in the micro semiconductor sample testing process.

[0045] A multi-functional semiconductor sample fixture of the present invention is a device applied to the fixation of tiny semiconductor samples. The device can be used as a load-bearing fixture for tiny samples when needles are pricked on a probe station, which is convenient for fixing and increasing the vacuum adsorption of the probe station. It can also be used as a sample holder when small samples are subjected to SEM / FIB analysis.

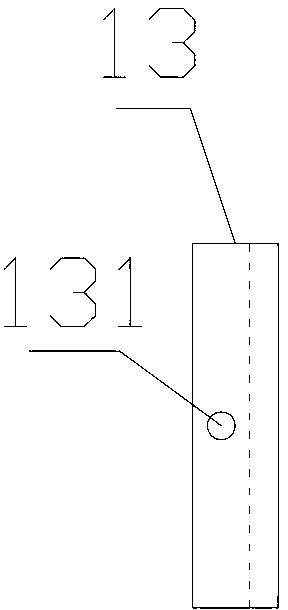

[0046] A multifunctional semiconductor sample holder of the present invention includes a bearing body and a base. A groove and a fixing device are arranged on the carrying body, and the fixing device fixes the semiconductor sample in the groove. The carrying body is also provided with at least three baffles and a bottom plate, and all the baffles are fixedly arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com