Non-contact electroscope and electroscope method

A non-contact electroscope technology, which is applied in the field of non-contact electroscope and electroscope, can solve the problems that affect the detection accuracy and safety hazards, and achieve the effect of eliminating safety hazards and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

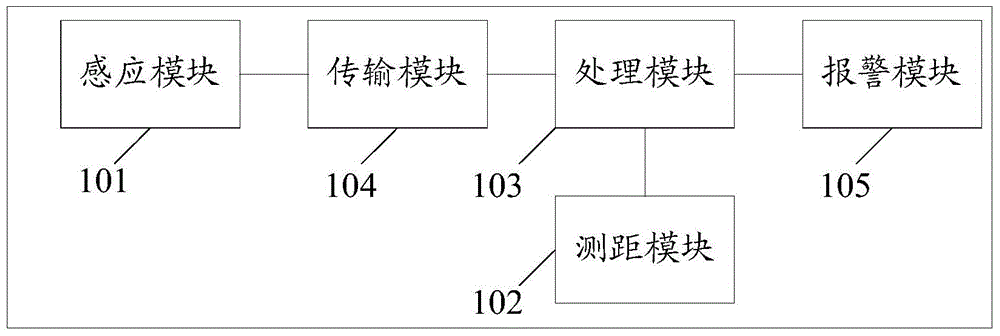

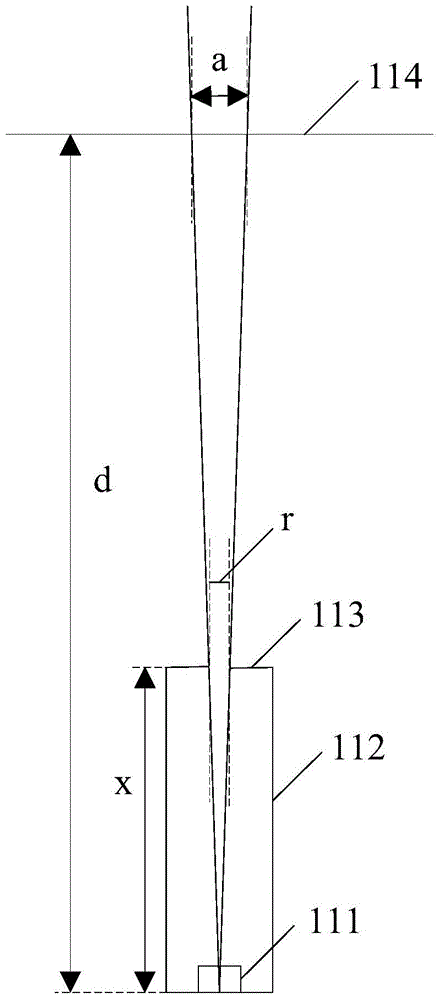

[0034] An embodiment of the present invention provides a non-contact electroscope, which is especially suitable for conducting electroscopes on ultra-high voltage objects to be tested such as high voltage lines, see Figure 1-2 , the electroscope consists of:

[0035] Induction module 101, used to detect the electric field strength of the object to be measured;

[0036] A ranging module 102, configured to detect the distance from the electroscope to the object to be measured;

[0037] The processing module 103 is configured to determine whether the object to be measured is charged according to the measured distance from the electroscope to the object to be measured and the measured electric field strength.

[0038] Specifically, the processing module 103 obtains the preset electric field strength corresponding to the measured distance from the electroscope to the object to be measured according to the corresponding relationship between the distance and the electric field stre...

Embodiment 2

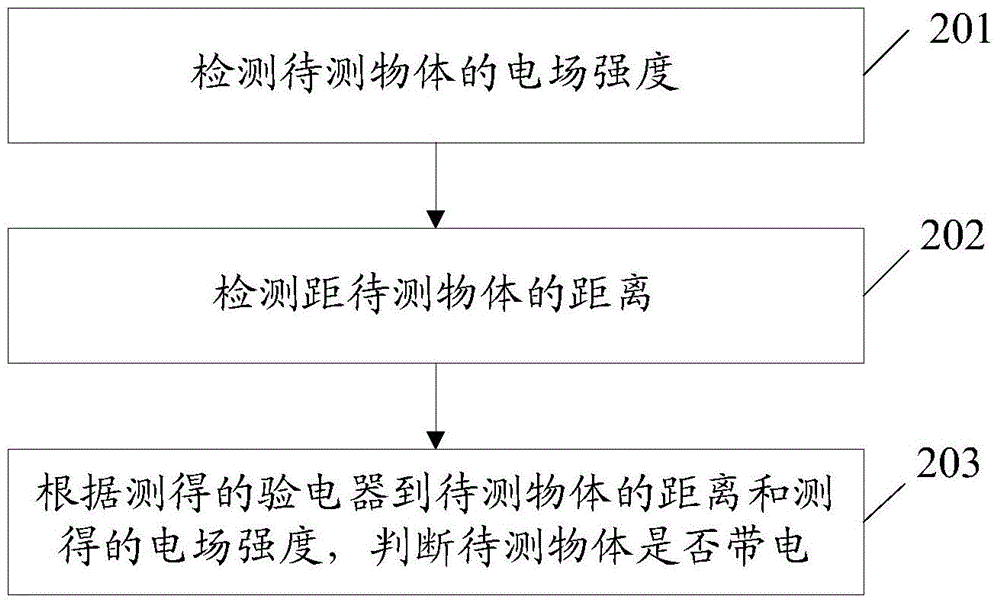

[0056] The embodiment of the present invention provides a non-contact electrical inspection method, which is especially suitable for electrical inspection of UHV objects such as high-voltage lines, see figure 2 , the method includes:

[0057] Step 201: Detect the electric field strength of the object to be measured;

[0058] Step 202: Detect the distance from the electroscope to the object to be measured;

[0059] Step 203: According to the measured distance from the electroscope to the object to be measured and the measured electric field strength, determine whether the object to be measured is charged.

[0060] Specifically, according to the corresponding relationship between the distance and the electric field strength, the preset electric field strength corresponding to the measured distance from the electroscope to the object to be measured is obtained, and the measured electric field strength is compared with the preset electric field strength. When the measured When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com