Light touch screen and manufacturing method thereof

A manufacturing method and technology of optical touch screen, applied in the direction of instrument, electrical digital data processing, input/output process of data processing, etc. The effect of human-computer interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

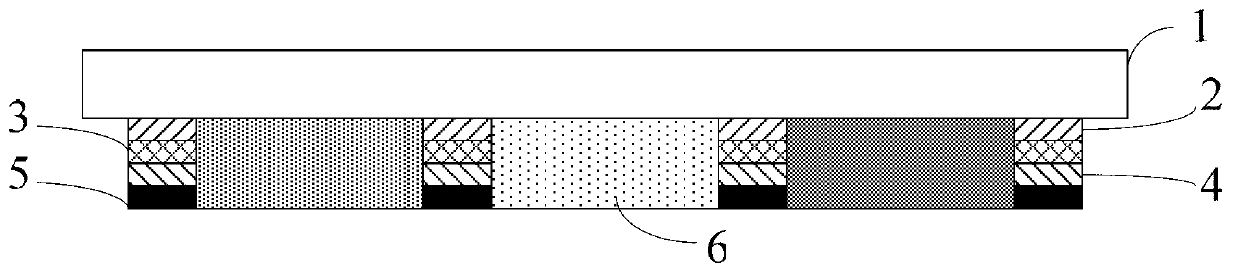

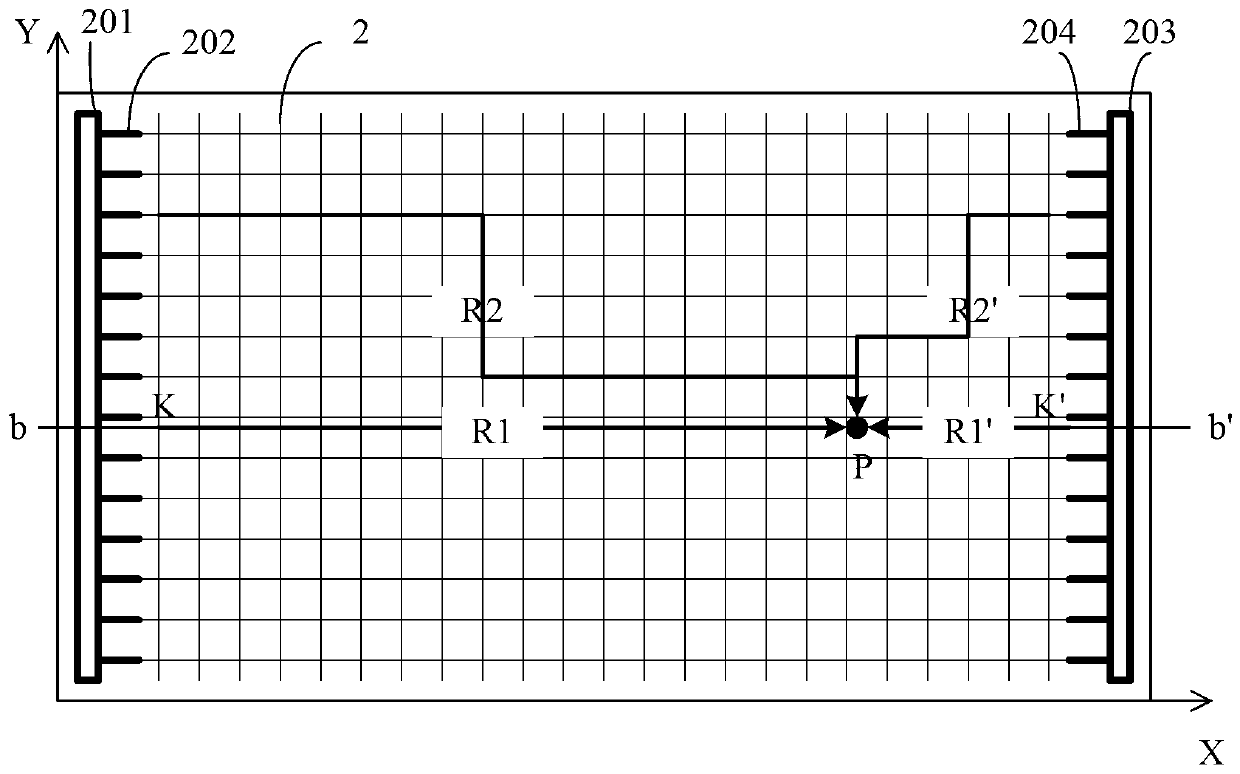

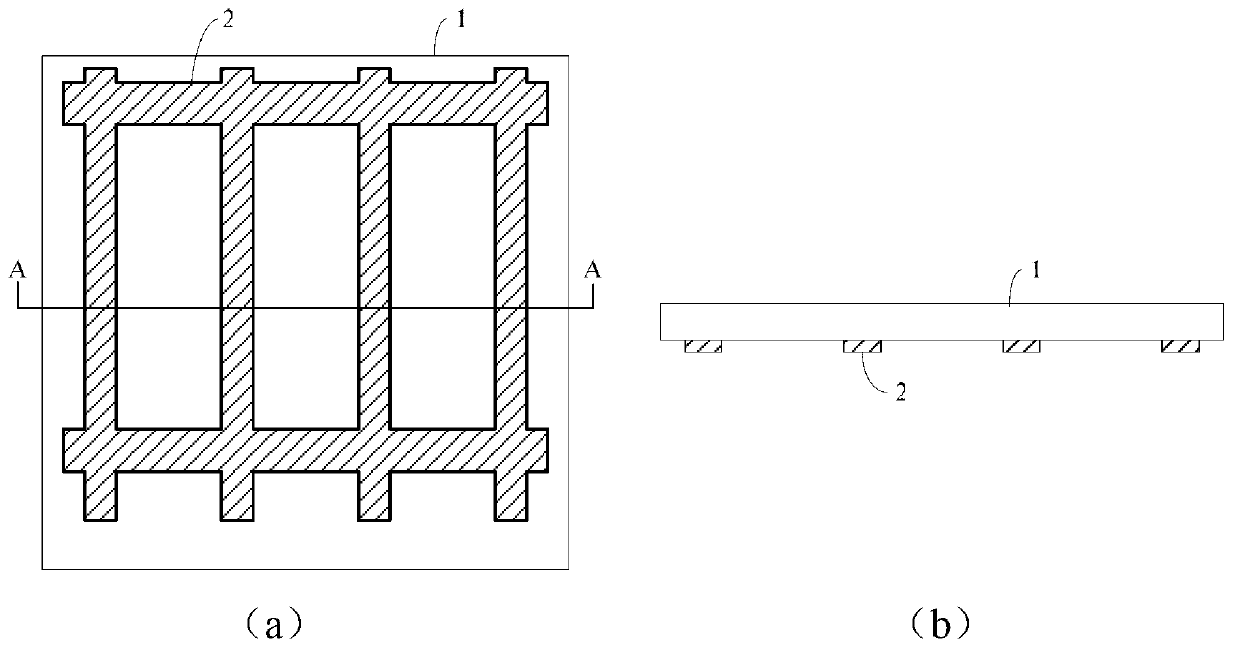

[0039] like figure 1 As shown, the optical touch screen of this embodiment includes: a first electrode layer 2 , a photosensitive material layer 3 and a second electrode layer 4 sequentially formed on a substrate 1 . Since the photosensitive material layer 3 needs to sense the light emitted by the light source, the first electrode layer 2 is a transparent electrode. In order to facilitate the determination of the position illuminated by the light source, the photosensitive material layer 3 is in the shape of a grid, while isolating the first electrode layer 2 and the second electrode layer 4 . Both the first electrode layer 2 and the second electrode layer 4 of the optical touch screen can be plate-shaped transparent electrodes, but the two layers of transparent electrodes reduce the transmittance of the optical touch screen.

[0040] In this embodiment, both the first electrode layer 2 and the second electrode layer 4 are grid-shaped, and the projection of the photosensitive...

Embodiment 2

[0065] like Figure 8 As shown, the optical touch screen of this embodiment is basically the same as that of Embodiment 1, except that the transparent first electrode layer 2 is a plate electrode. Compared with Example 1, the transmittance is reduced to a certain extent, but the plate-shaped first electrode layer 2 can play an electrostatic shielding role when no touch occurs, and can prevent external electrical signals from affecting the electrical signals of the display panel. Impact. In terms of the manufacturing method, it is only necessary to make the first transparent electrode layer 2 into a full-surface electrode without etching. The principle of positioning the light emitted by the light source in this embodiment is the same as that in Embodiment 1, and will not be repeated here.

Embodiment 3

[0067] like Figure 9 As shown, the optical touch screen of this embodiment is basically the same as that of Embodiment 1, except that the transparent second electrode layer 4 is a plate electrode. Compared with Example 1, the transmittance is reduced to a certain extent, but the plate-shaped second electrode 4 acts as an electrostatic shield, preventing external electrical signals from affecting the electrical signals of the display substrate. In terms of the manufacturing method, it is only necessary to make the second transparent electrode layer into a plate-shaped electrode layer 4 . The principle of locating the light emitted by the external light source in this embodiment is the same as that in Embodiment 1, and will not be repeated here.

[0068] In the above embodiments, light is emitted by a hand-held light-emitting device, such as a laser pointer. This hand-held lighting device includes:

[0069] The first light emitter and its first control button, the first cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com