Method for preparing high In component AlInN thin film

A thin-film, high-temperature technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as AlInN composition fluctuation, film quality deterioration, and large lattice mismatch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

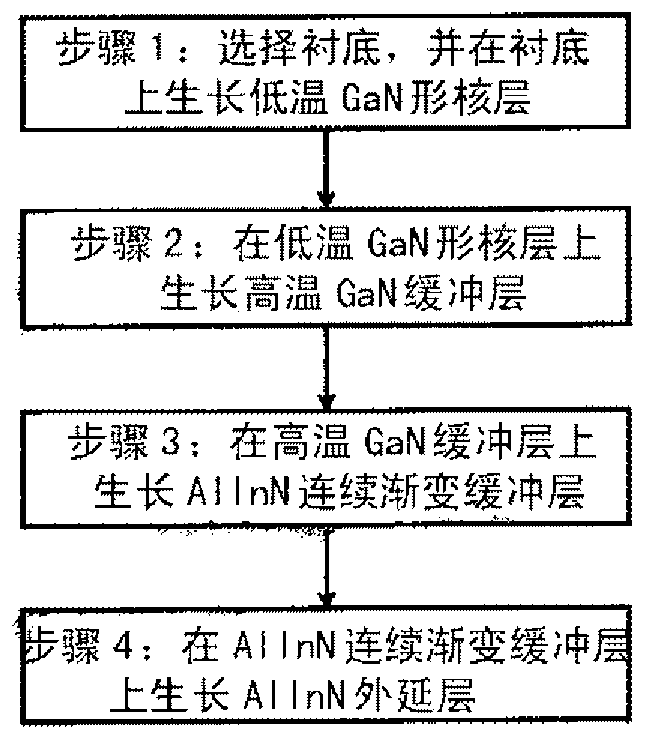

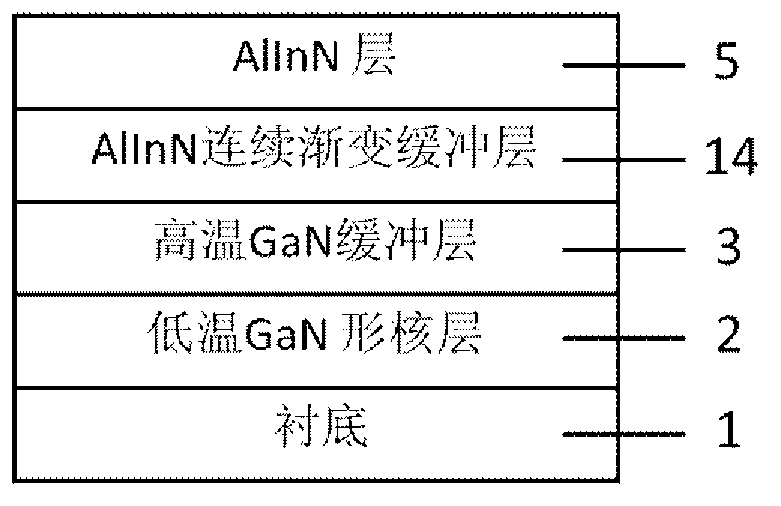

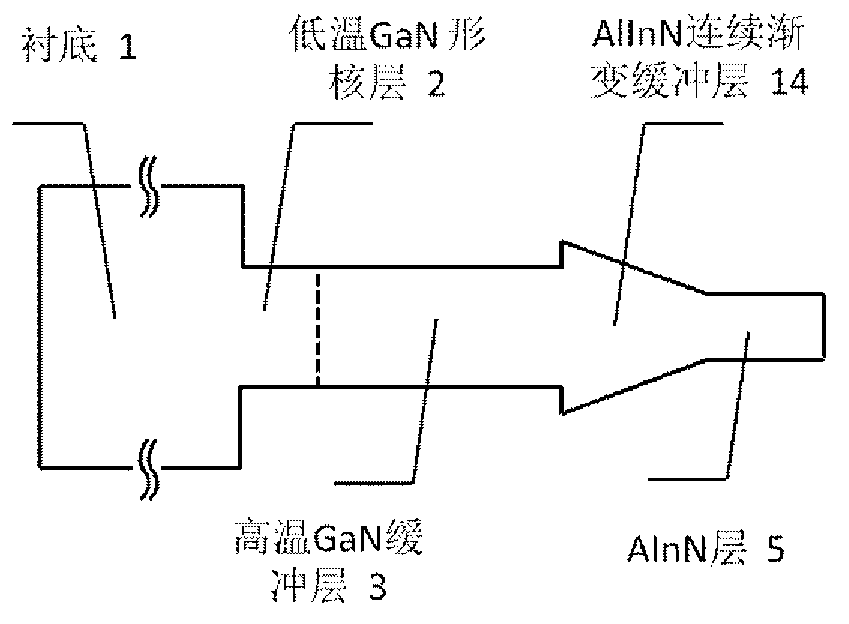

[0030] see figure 1 and figure 2 Shown, the present invention provides a kind of preparation method of high In composition AlInN film, and this method is the first embodiment, comprises the following steps:

[0031] Step 1: grow a low-temperature GaN nucleation layer 2 on a substrate 1, the material of the substrate 1 is sapphire, Si, GaN, SiC or AlN, the thickness of the low-temperature GaN nucleation layer 2 is 20-30nm, and the low-temperature The function of the nucleation layer is mainly to initially release the stress caused by the lattice mismatch between the substrate and the buffer layer;

[0032] Step 2: grow a high-temperature GaN buffer layer 3 on the low-temperature GaN nucleation layer 2. The high-temperature GaN buffer layer 3 has a thickness of 1-3 μm. The high-temperature GaN buffer layer is grown mainly to obtain a smooth film surface, which is the foundation of the subsequent buffer layer. Prepare for growth.

[0033] Step 3: On the high-temperature GaN b...

no. 2 example

[0035] see figure 1 , Figure 4 and Figure 5 As shown, the present invention provides a method for preparing a high In composition AlInN thin film, which is a second embodiment, comprising the following steps:

[0036] Step 1: growing a low-temperature GaN nucleation layer 2 on a substrate 1, the material of the substrate 1 is sapphire, Si, GaN, SiC or AlN, and the thickness of the low-temperature GaN nucleation layer 2 is 20-30nm;

[0037] Step 2: growing a high-temperature GaN buffer layer 3 on the low-temperature GaN nucleation layer 2, and the thickness of the high-temperature GaN buffer layer 3 is 1-3 μm;

[0038] Step 3: growing a multi-layer AlInN composition transition buffer layer 24 on the high temperature GaN buffer layer. The In composition of each layer in the multi-layer AlInN composition transition buffer layer 24 gradually increases from bottom to top, and the bottom In composition is 0.18. This design mainly considers the Al 0.82 In 0.18 N is lattice-mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com