Method for controlling steam temperature of outlet of DSG (Direct Steam Generation) trough type solar thermal collector

A trough solar energy and steam temperature technology applied in the field of solar thermal utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with accompanying drawing, the technical scheme of invention is described in detail:

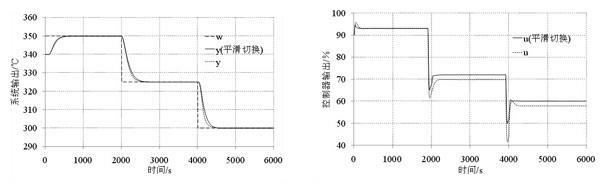

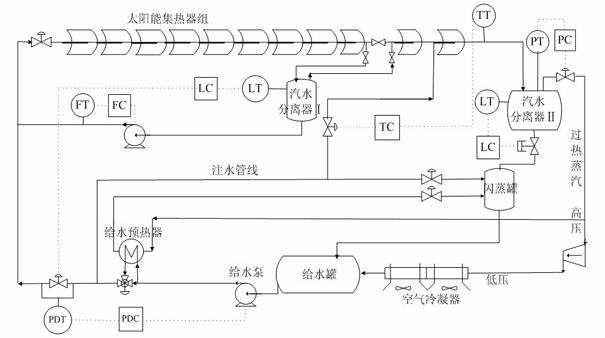

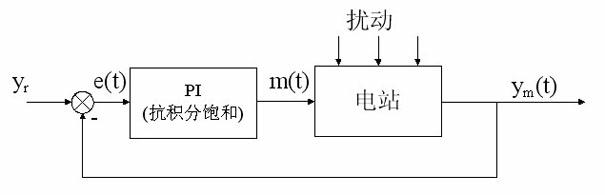

[0055] like figure 1 As shown, its heat collector is composed of several groups of heat collecting tubes. A steam-water separator is installed at the end of the evaporating section of the heat collecting tube group, which structurally separates the superheating section and the evaporating section of the heat collecting tube group. The water supply at the entrance of the evaporation section is greater than the evaporation, and its circulation ratio is greater than 1. The dry saturated steam separated by the steam-water separator enters the superheating section and is heated into superheated steam. A "spray water desuperheating device" is installed at the inlet of the last heat collecting tube group in the superheating section to adjust the steam temperature at the outlet of the heat collecting field. This mode of DSG trough system has high reliability and is mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com