Metal ion elimination filter

A metal ion and filter technology, applied in the direction of ion exchange, cation exchange, organic cation exchanger, etc., can solve heating and other problems, and achieve the effect of eliminating the guided engine, reducing heat load, and eliminating the deterioration of installability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

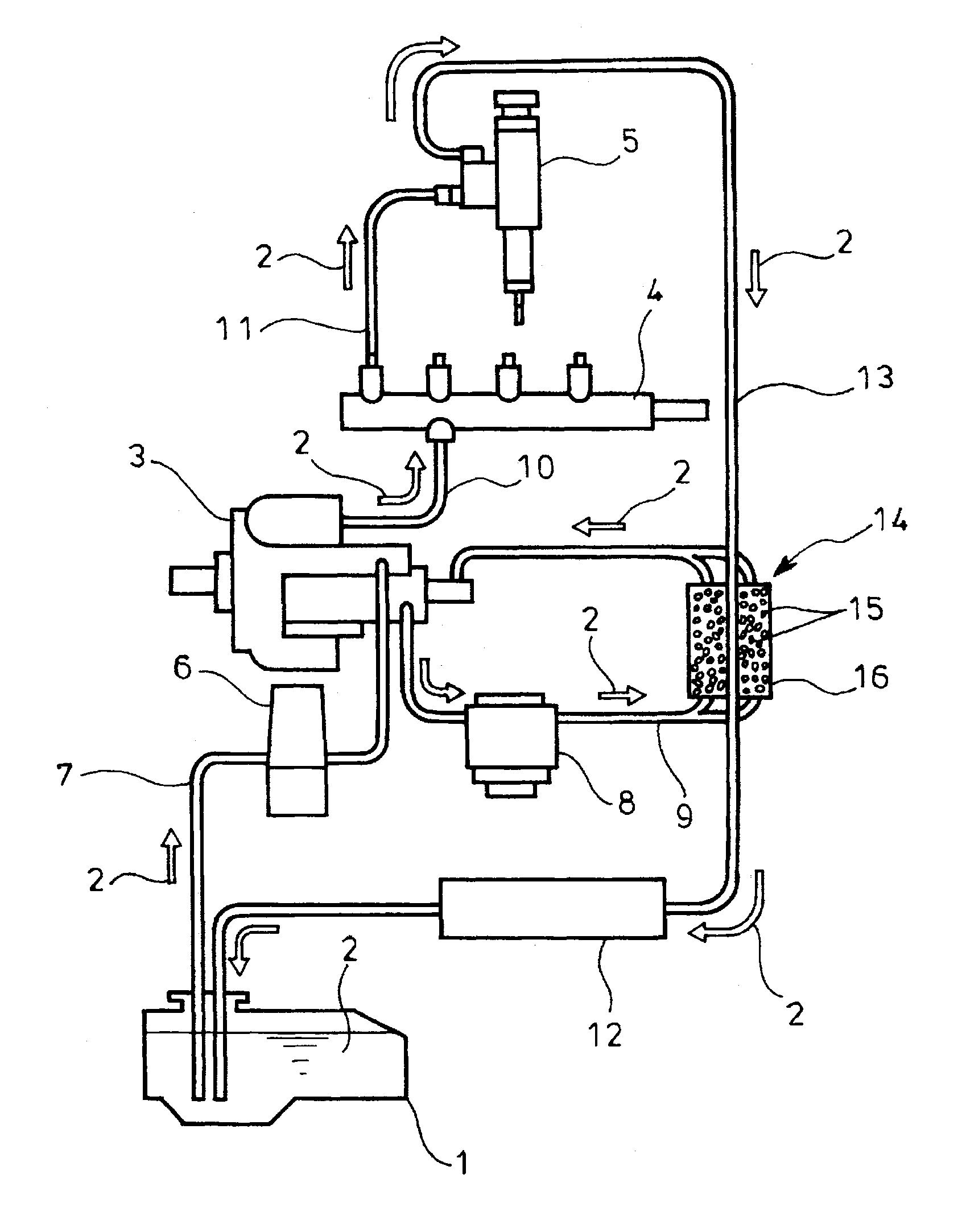

[0032] Embodiments of the present invention will be described below with reference to the drawings.

[0033] figure 1 One embodiment of the invention is shown, figure 1 An example in which the metal ion removing filter of the present invention is applied to a general common rail type fuel injection device is schematically shown. In this illustrated example, the fuel 2 in the fuel tank 1 is pressurized by the fuel pump 3 .

[0034] The fuel pump 3 is driven by the output of the engine, and can boost the fuel 2 to a required predetermined pressure, supply it to the common rail 4, and store it in a pressure accumulation state. The fuel 2 in the common rail 4 is supplied to the A plurality of injectors 5 for each cylinder supply and inject into each cylinder.

[0035] Then, among the fuel supplied from the common rail 4 to the injector 5 , the remaining fuel 2 not used for injection to each cylinder is returned from each injector 5 to the fuel tank 1 as return fuel 2 .

[0036]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com