Damping arrangement

A damping device and damping technology, applied in the direction of fluid pressure actuators, non-mechanical drive clutches, pipes/pipe joints/pipe fittings, etc., to achieve reliable and fast opening effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

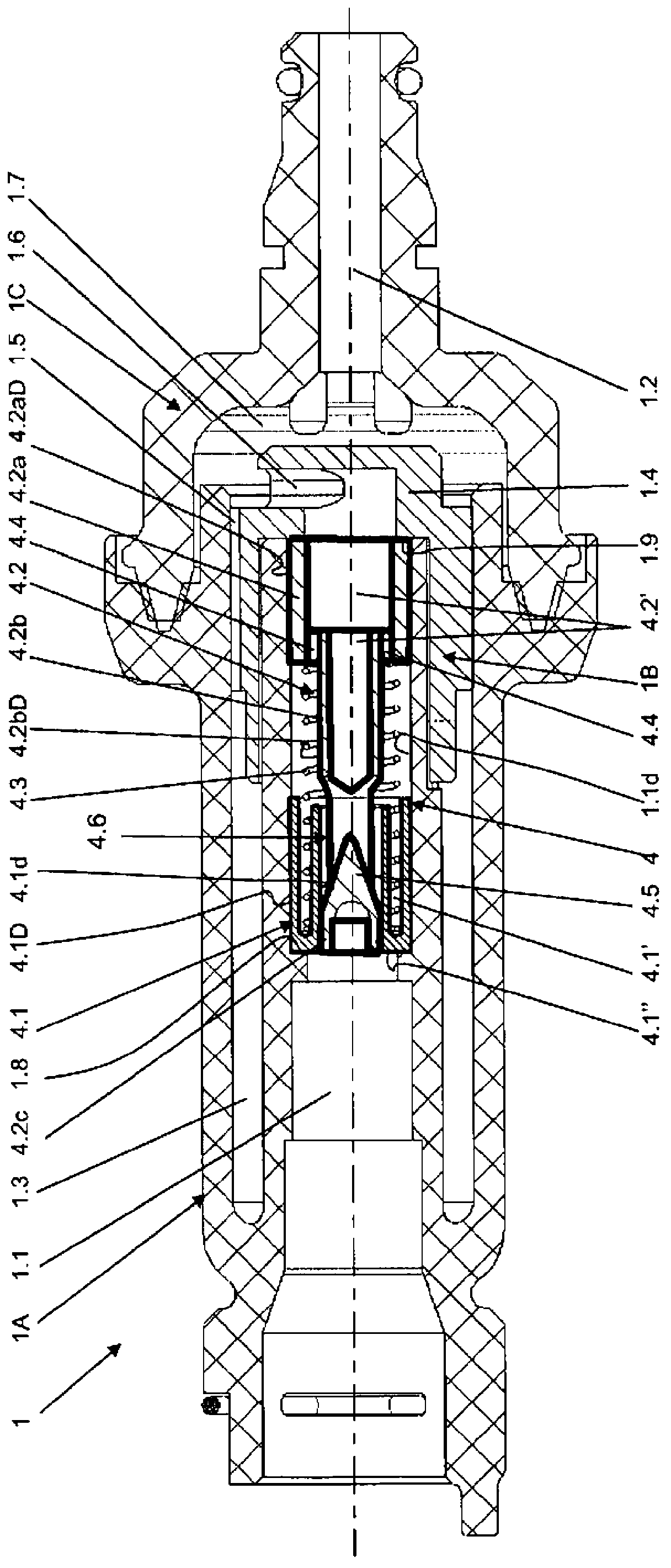

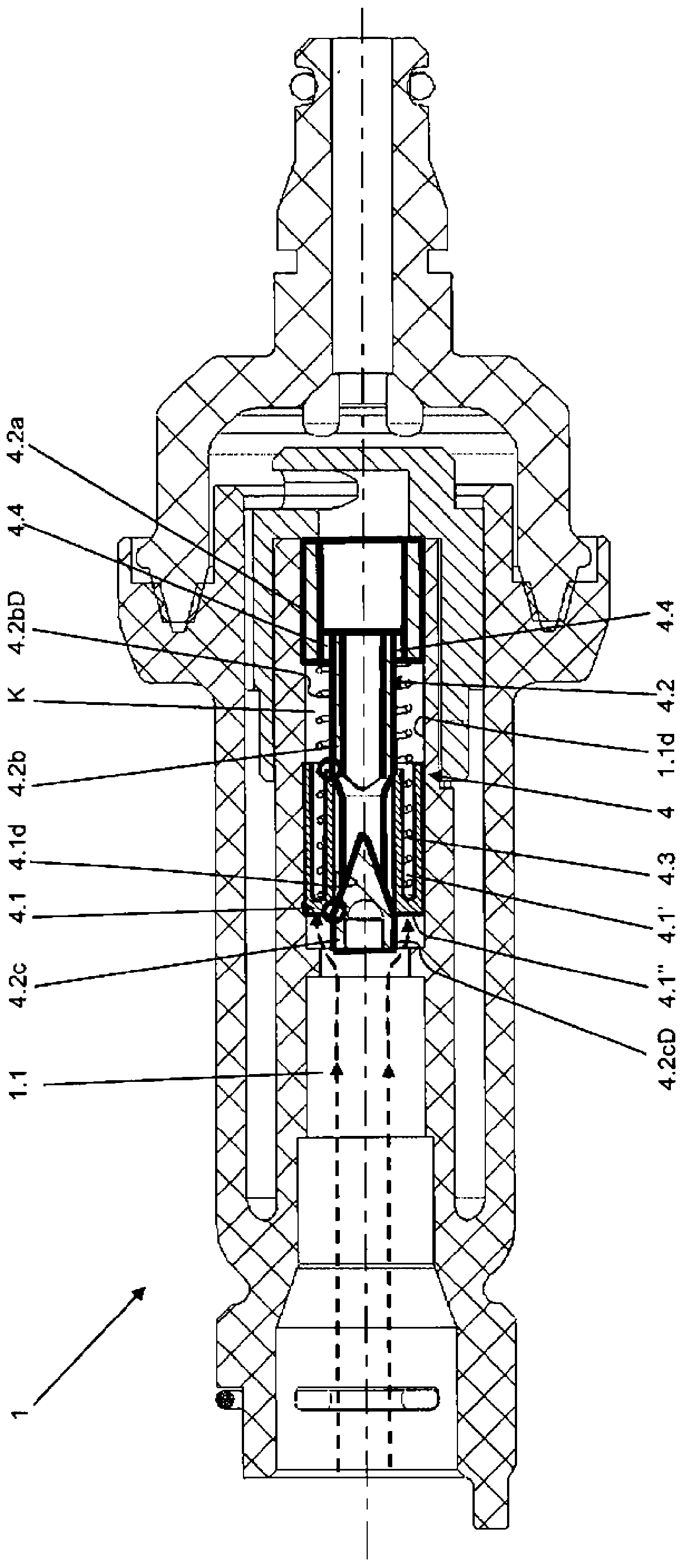

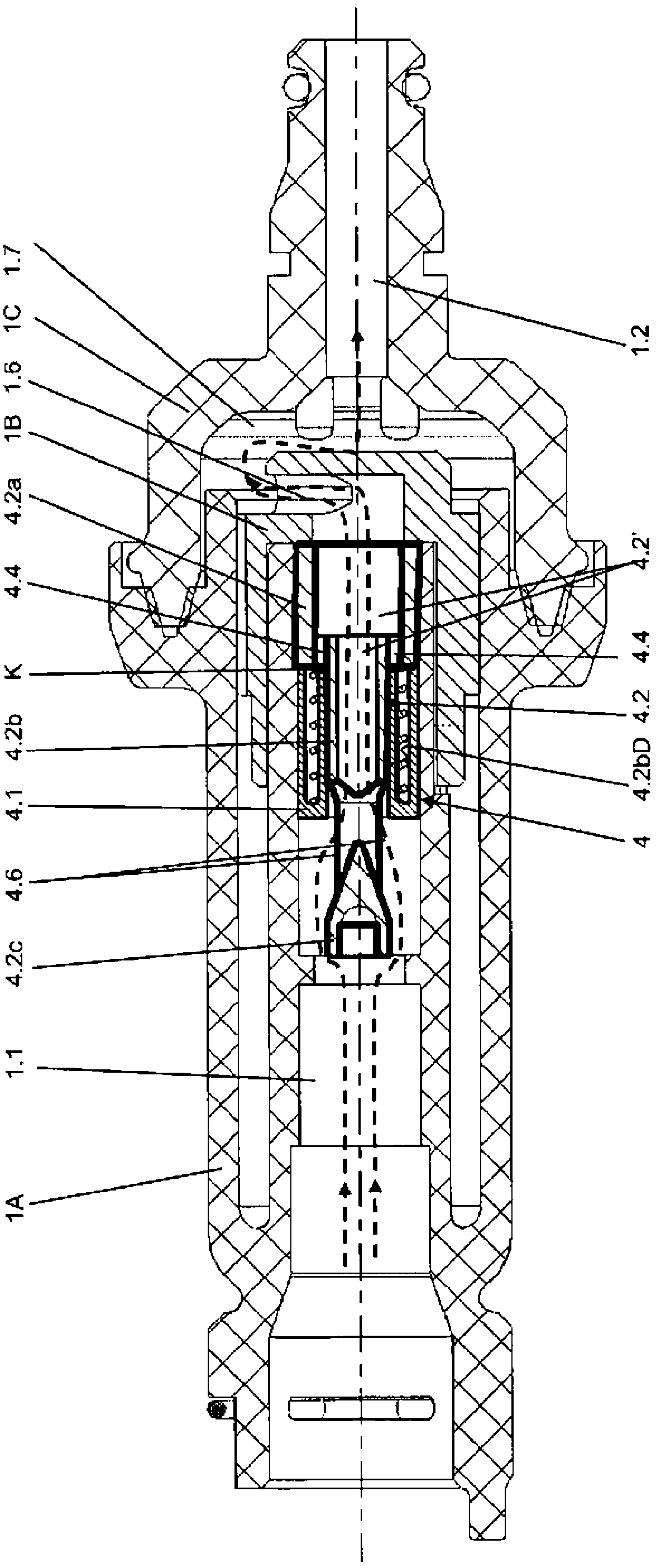

[0025] exist Figures 1 to 3 shows a damping device according to the invention, which consists of a shock absorber 1 for damping vibrations. A shock absorber 1 arranged coaxially to a pressure line (not shown here) is shown in longitudinal section. The shock absorber 1 operating according to the Helmholtz principle consists of three basic components: housing 1A, press-in part 1B and cover 1C. They are arranged concentrically with the through-flow opening 1.1 of the housing 1A or with the through-opening 1.2 of the cover 1C through which fluid can flow. The press-in part 1B is pressed into the annular space 1.3 of the housing 1A and points with its base 1.4 in the direction of the cover 1C. The press-fit part 1B is provided with grooves 1.5 on its outer circumference, which form a supply line to the annular space 1.3. Via a radially outwardly directed opening 1.6 of the press-fit part 1B, there is a connection to a through-opening 1.2 of the cover via a chamber 1.7 of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com