Method for producing positive electrode active material for lithium ion secondary batteries

A positive active material, secondary battery technology, applied in battery electrodes, lithium storage batteries, chemical instruments and methods, etc., can solve problems such as insufficient discharge capacity, achieve reduction in initial capacity, improve cycle characteristics, and high durability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

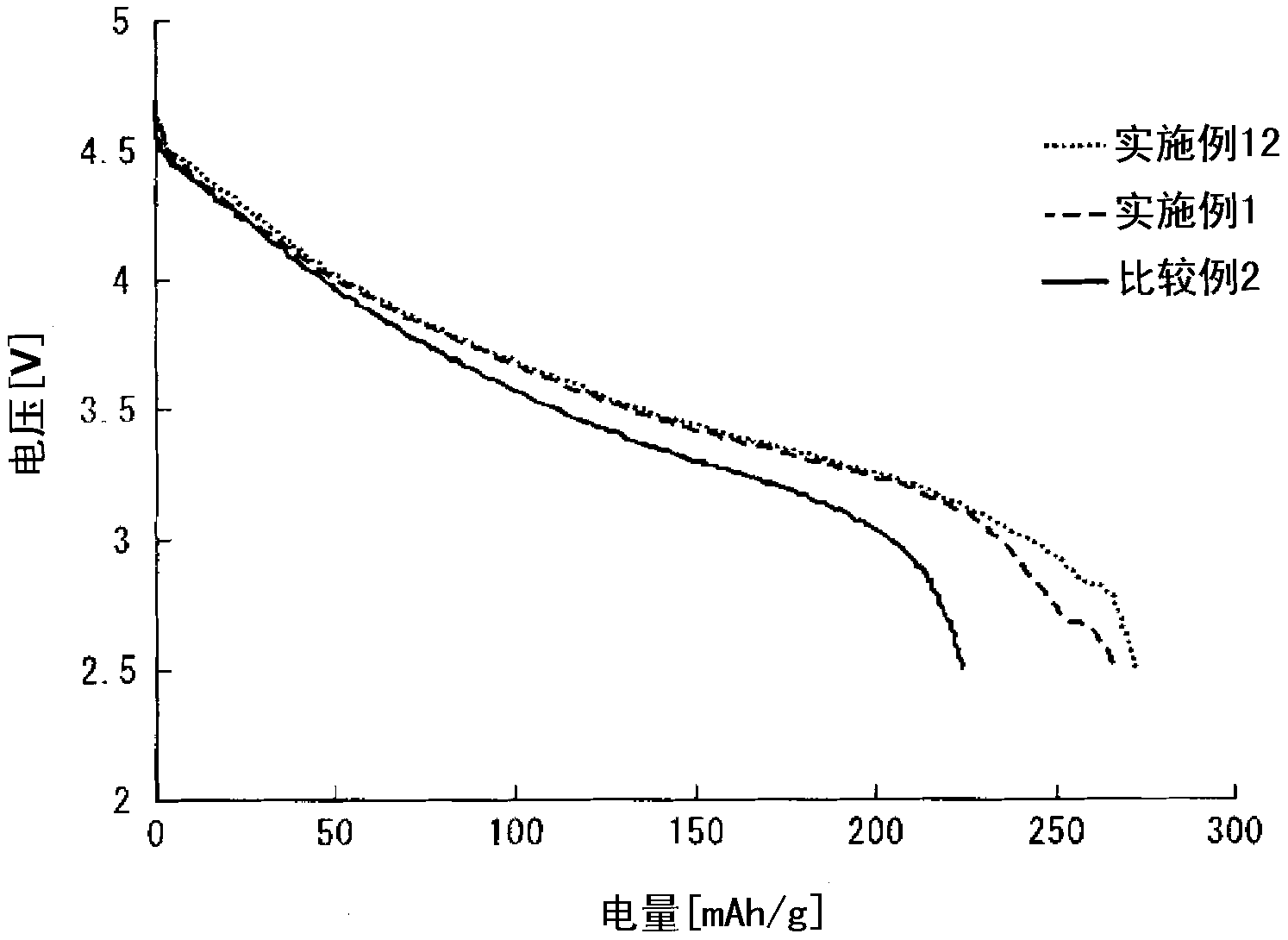

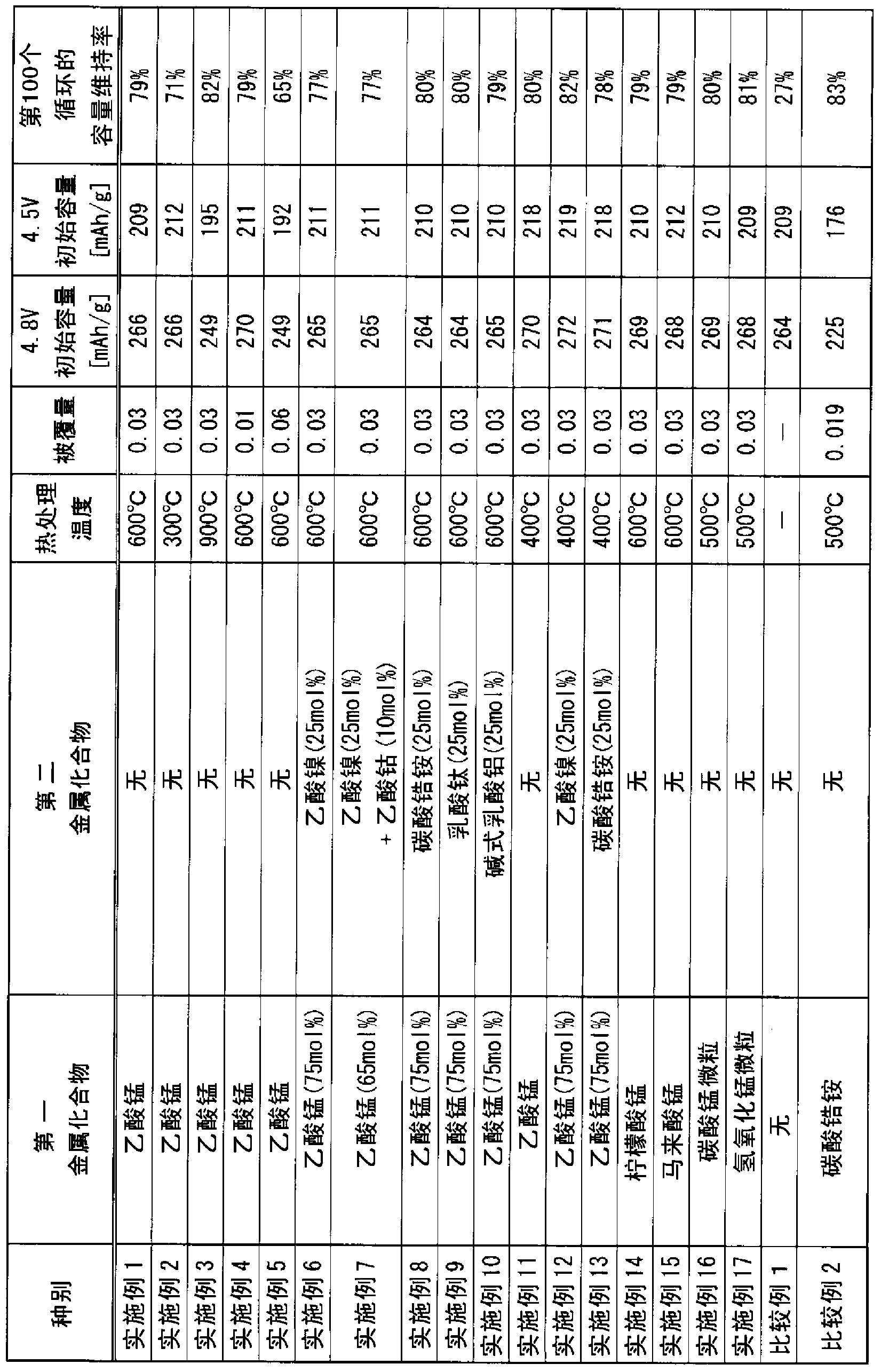

[0128] (Example 1)

[0129] In manganese acetate 4-hydrate (chemical formula: Mn(CH 3 COO) 2 ·4H 2 O, molecular weight: 245.09) 17.8 g of distilled water was added to 7.2 g to prepare a pH 7.0 Mn solution (composition (1)).

[0130] Next, with respect to 15 g of the lithium-containing composite oxide of the example being stirred, 3.6 g of the prepared Mn aqueous solution was spray-added, and the lithium-containing composite oxide of the example and the Mn aqueous solution were mixed and brought into contact. Next, the resulting mixture was heated at 600° C. for 3 hours in an oxygen-containing atmosphere to obtain the positive electrode active material of Example 1. The positive electrode active material is composed of an oxide containing Mn element more present on the surface of the lithium-containing composite oxide. Particle composition.

[0131] In the positive electrode active material, the manganese coated with the Mn aqueous solution is calculated as {(coated Mn) in molar rat...

Embodiment 6

[0135] (Example 6)

[0136] Except that the coating conditions of the manganese compound on the surface of the lithium-containing composite oxide were set to the conditions shown in Table 1 below using a mixed solution of manganese acetate and nickel acetate, the positive electrode activity was obtained by the same procedure as in Example 1 above. substance. Here, {(Total number of moles of coated Mn and Ni) / (Total number of moles of Ni, Co and Mn of lithium-containing composite oxide before application)}=0.03, and the molar ratio of coated Mn to Ni is Mn: Ni=75:25.

Embodiment 7

[0137] (Example 7)

[0138] Except that the coating conditions of the manganese compound on the surface of the lithium-containing composite oxide were set to the conditions shown in Table 1 below using a mixed solution of manganese acetate, nickel acetate, and cobalt acetate, the same procedure as in Example 1 was performed. The positive electrode active material is obtained. Here, {(Total number of moles of Ni, Co, Mn to be coated) / (Total number of moles of Ni, Co, and Mn of lithium-containing composite oxide before application)}=0.03, the moles of coated Mn, Ni, and Co The ratio is Mn:Ni:Co=65:25:10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com