Jig for containing hub

A hub and packaging technology, used in packaging, transportation and packaging, containers to prevent mechanical damage, etc., can solve the problems of bicycle hub workpieces bumping, affecting the appearance of bicycle hub workpieces, and scrapping bicycle hub workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

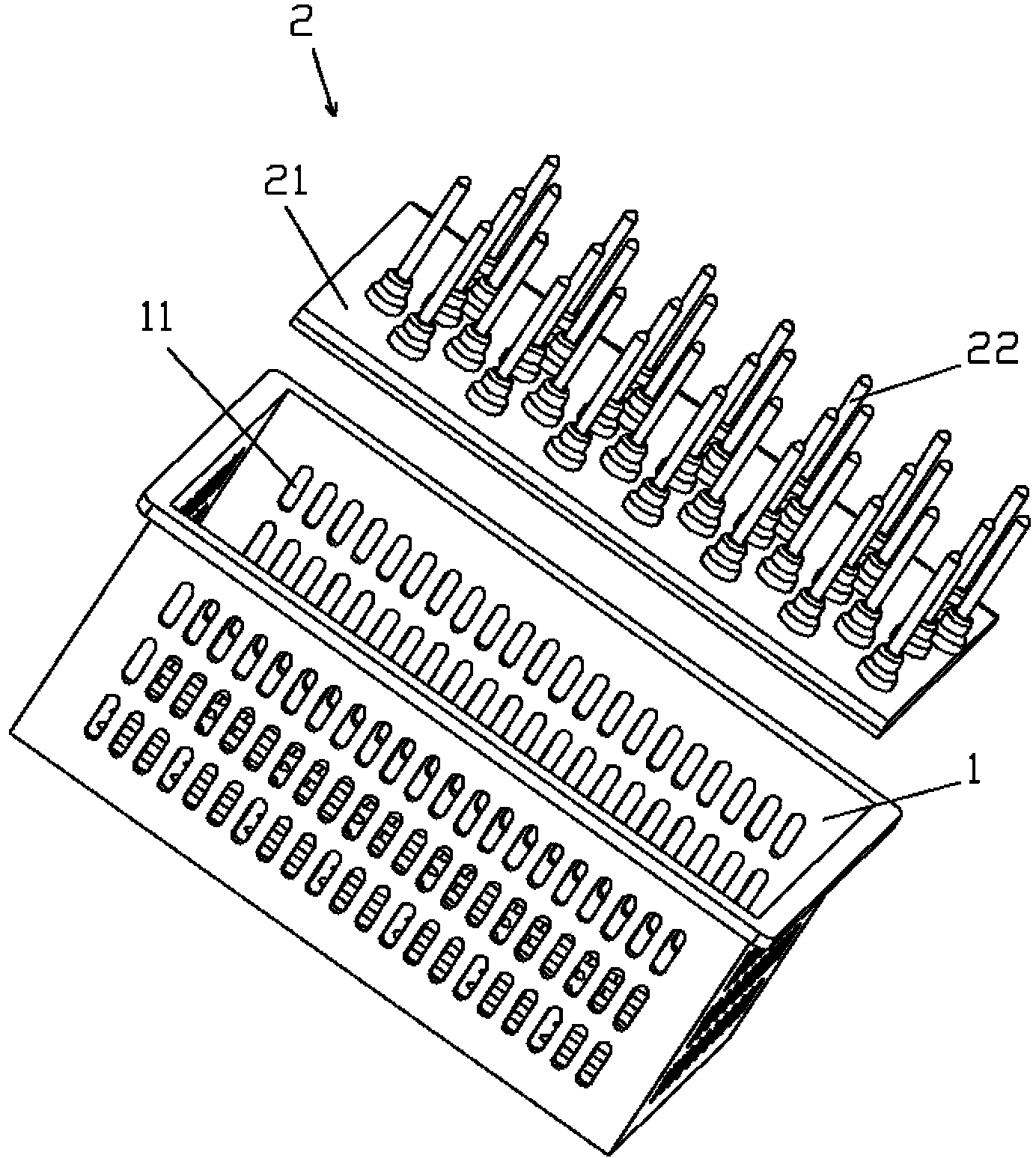

[0012] See figure 1 , 2 As shown: the hub fitting jig of the present invention includes a transport frame 1, which can be in any shape. In this embodiment, the transport frame 1 is a square frame, and the hub inserting plate 2 is placed in the transport frame 1. The hub Insert plate 2 is made of a base plate 21 and several hub inserting rods 22, and described hub inserting bar 22 is fixed on the base plate 21, and base plate 21 is rectangular and the size of base plate 21 is slightly smaller than the size of carrying frame 1 rectangular frame mouth,.

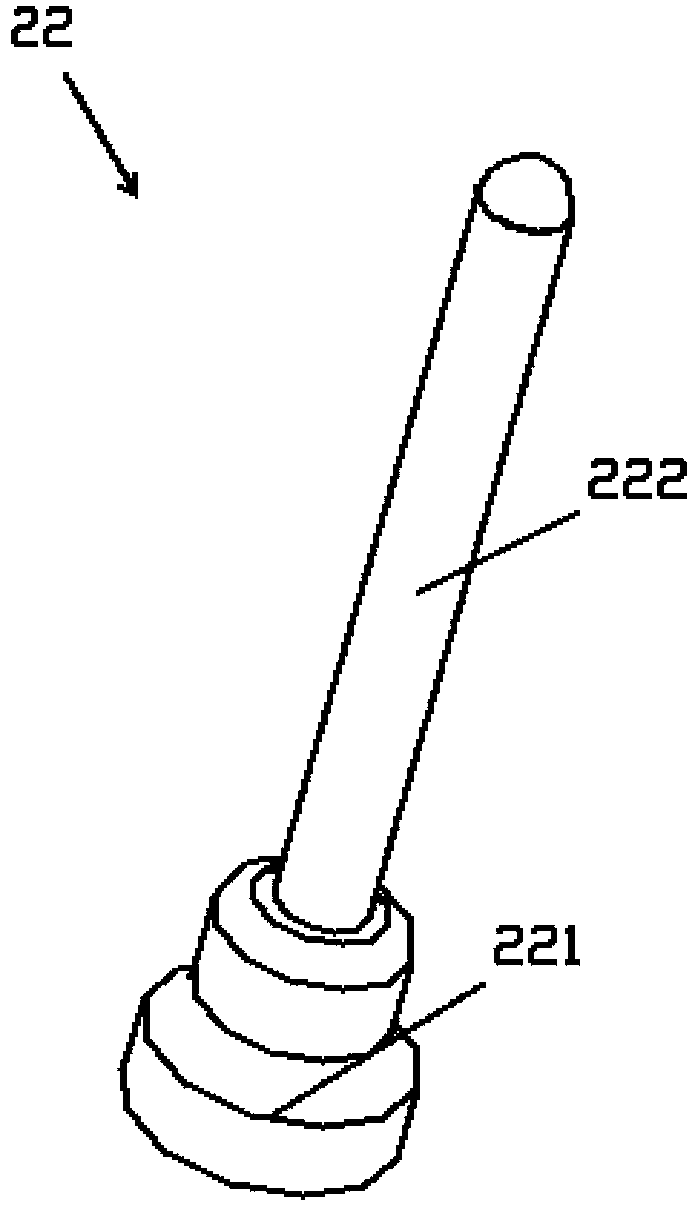

[0013] Meanwhile, the hub inserting rod 22 is composed of a boss 221 and an inserting rod 222 , and the inserting rod 222 is fixed on the boss 221 .

[0014] In addition, several waist-shaped holes 11 are formed on the side wall and the bottom of the transport frame 1 .

[0015] The above descriptions are only preferred embodiments embodying the principles of the present invention, and do not limit the protection scope of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com