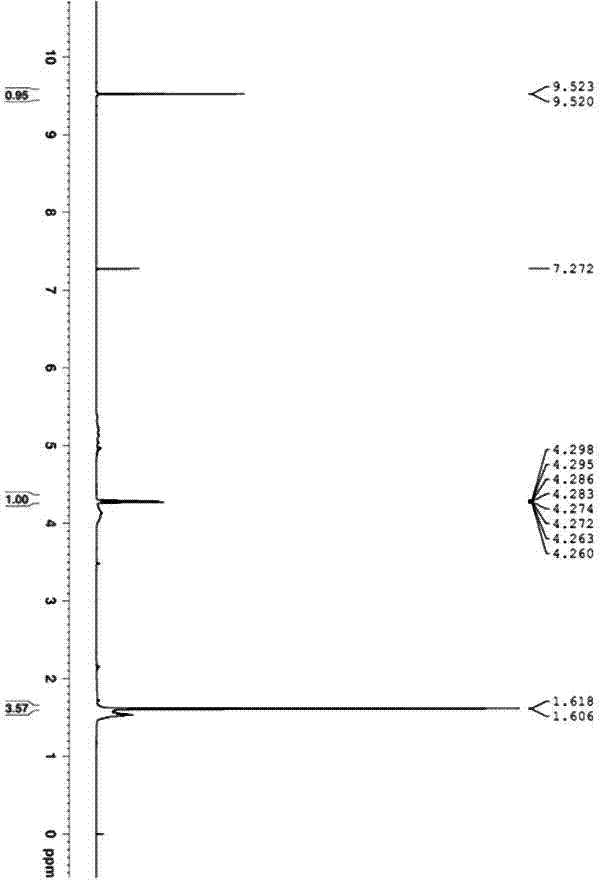

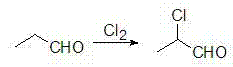

Method for synthesizing 2-chloropropionaldehyde

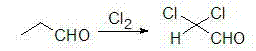

A technology of chlorpropionaldehyde and chlorine gas, which is applied in the direction of chemical instruments and methods, preparation of organic compounds, carbon-based compounds, etc., can solve the problems of high acidity of products, many drying operation steps, and overheating, and achieve product purity and High yield, mild reaction conditions, and the effect of avoiding water removal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 102g (1.2 moles) of dichloromethane and 5g (0.05 moles) of 36.5% hydrochloric acid into a 250mL four-neck flask equipped with a stirrer and a thermometer, keep away from light, control the temperature of the reaction system at 10-15°C, and then blow with nitrogen. Sweep the system for 10 minutes, then pass chlorine gas, the flow rate of chlorine gas is 17L / hr. After 10 minutes of chlorine gas flow, 58.1 g (1 mole) of propionaldehyde was added dropwise for a total of 2 hours. After the dropwise addition, chlorine gas was passed for 1 hour to react, then chlorine gas was stopped, and nitrogen gas was continued to purge excess chlorine gas in the system for 30 minutes. Get chlorinated solution. Distill the obtained chlorinated liquid under reduced pressure, and collect the distillate at 60-62°C / 185mmHg. The product has a purity of 99%, a yield of 92.4%, and a b.p. of 84-86°C.

Embodiment 2

[0027] Operation process is the same as embodiment 1, and catalyst is iron trichloride 8.1g (0.05 mol), makes chlorinated liquid, and the chlorinated liquid of gained is subjected to vacuum distillation, receives the cut of 60~62 ℃ / 185mmHg. Product yield 90.2%, b.p.84~86℃.

Embodiment 3

[0029] The operation process is the same as in Example 1, the reaction temperature is 50° C., and the chlorinated liquid is obtained, and the obtained chlorinated liquid is subjected to vacuum distillation, and the fraction of 60~62° C. / 185 mmHg is collected. Product yield 84.5%, b.p.84~86℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com