Individual pitch control method and individual pitch control device of wind generation set

An independent pitch and wind turbine technology, which is applied in the control of wind turbines, wind energy power generation, wind turbines, etc., can solve the problems of complex control, and achieve the effects of simple and reliable control, low cost, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

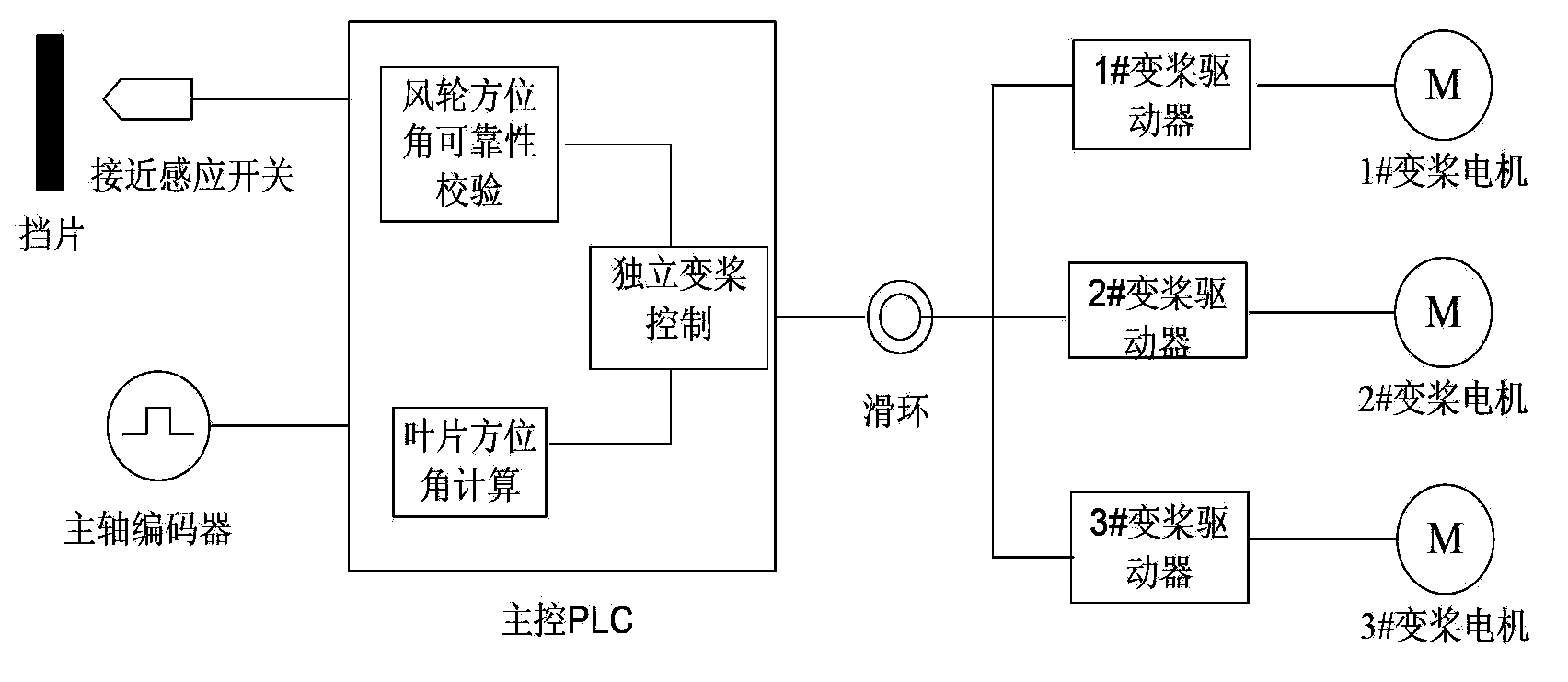

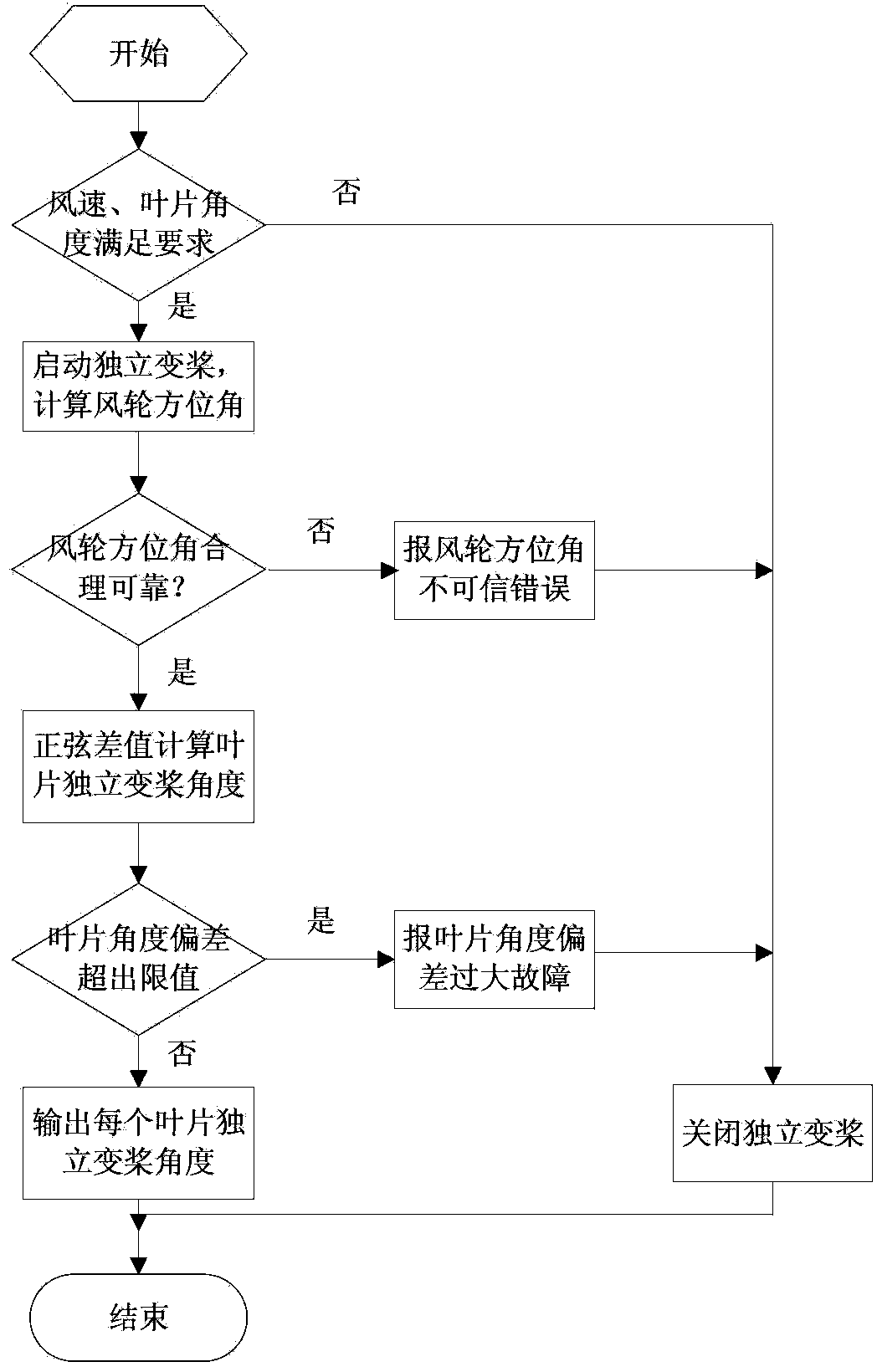

[0025] like figure 1 As shown, the controller adopts PLC, and the internal functional modules of the PLC should include the wind rotor blade azimuth angle calculation module, the wind rotor azimuth angle reliability verification module, and the independent pitch control module, and the PLC sampling connection is used to measure the wind rotor azimuth angle. The controller, the proximity sensor switch used to verify the azimuth angle of the wind rotor, the PLC output is connected to the independent pitch driver, and the independent pitch driver is connected to the pitch motor. The proximity sensor switch is installed on the main frame near the main shaft flange, and the supporting block of the proximity sensor switch is installed at the position of the main shaft flange, and rotates with the main shaft to ensure that the switch can sense the block normally. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com