Pipe bursting shutoff valve

A shut-off valve and pipe burst technology, which is applied in the field of shut-off valves, can solve the problems of difficulty in realizing the adjustment of the control flow size and the like, and achieve the effect of reliable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

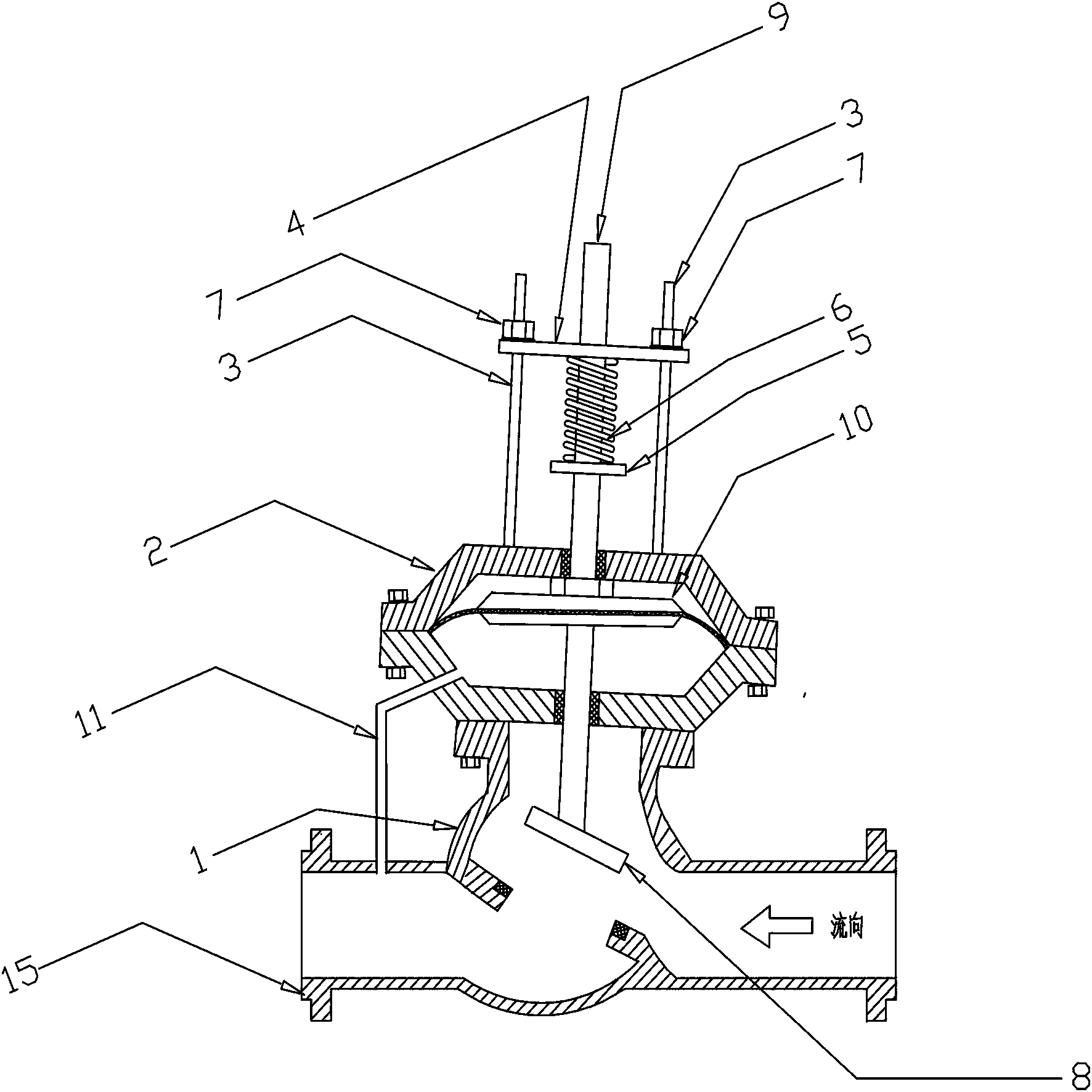

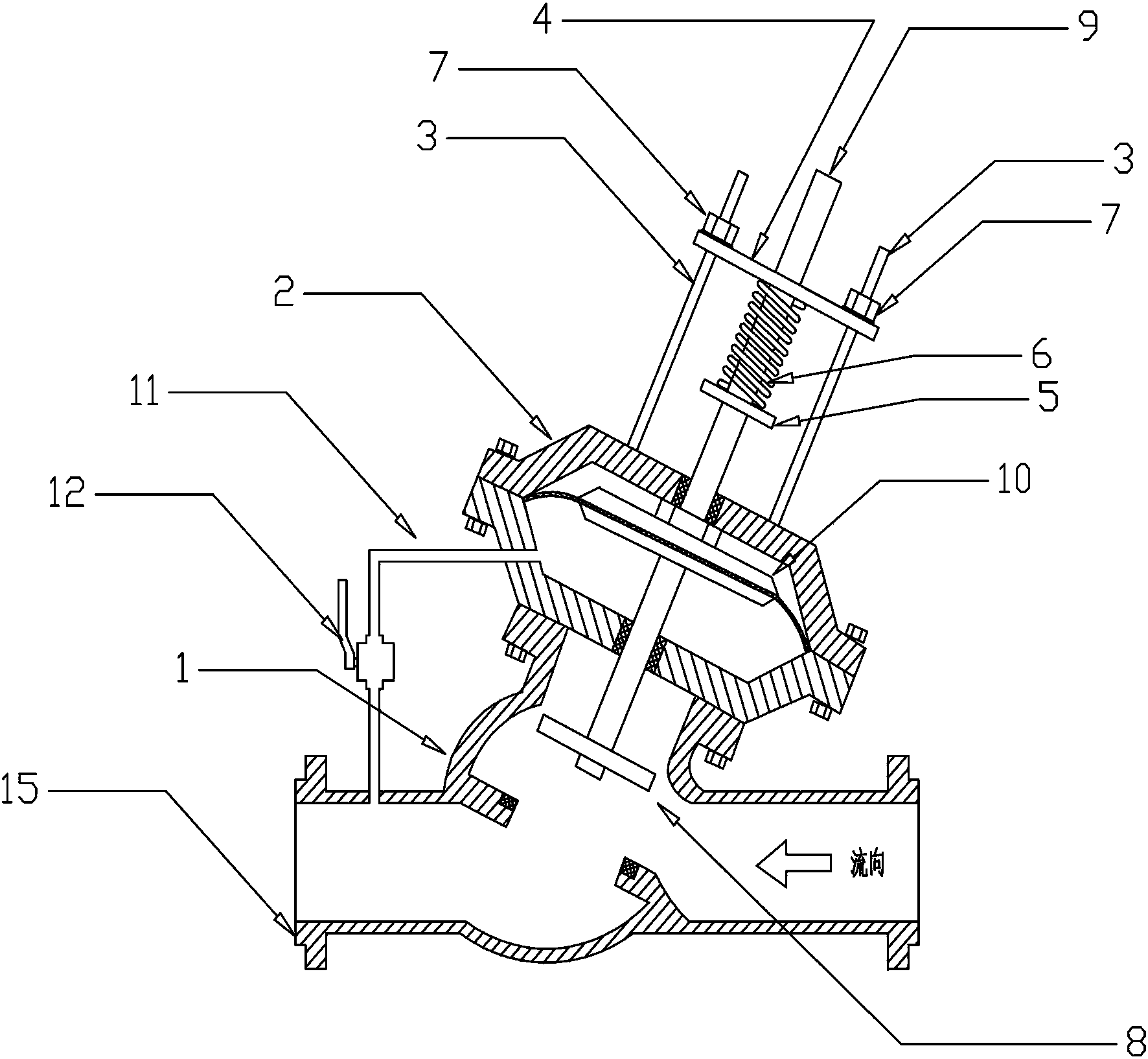

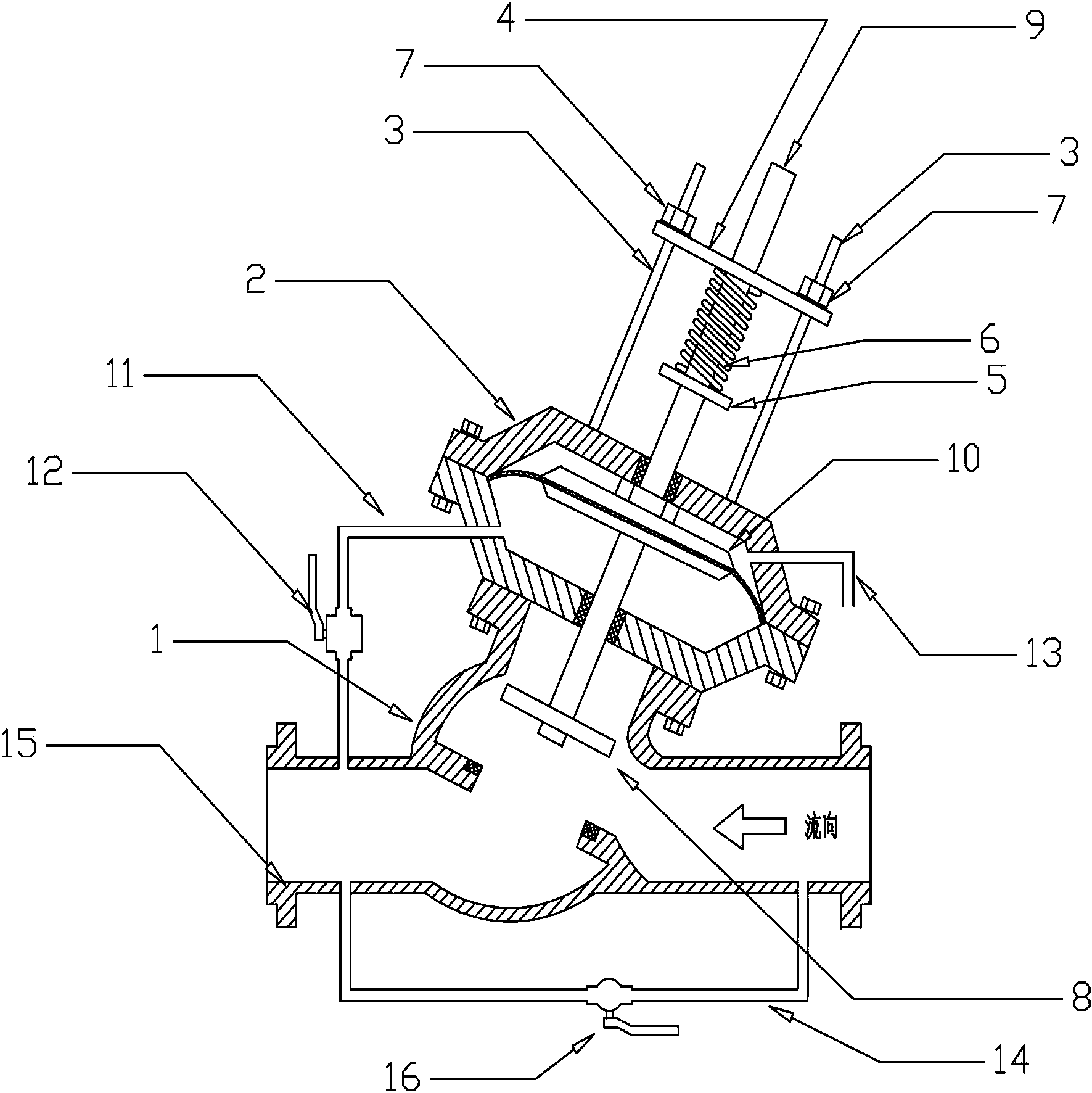

[0021] Such as figure 1 In, a blast pipe shutoff valve includes a valve body 1 arranged on a pipe body 15 to communicate with the inside of the pipe body 15. The blast pipe shutoff valve further includes a control chamber 2, a valve shaft 9, and the valve shaft 9 in turn. The first elastic component on the upper part, the diaphragm piston 10, the valve disc 8, the control chamber 2 is connected with the valve body 1, the valve shaft 9 passes through the control chamber 2 and enters the valve body 1, and the diaphragm piston 10 is provided with In the control chamber 2, the control chamber 2 is rigidly connected with the diaphragm piston 10, and the chamber system 2 is divided into an independent upper chamber and a lower chamber. The valve disc 8 is arranged in the valve body 1, and the lower chamber communicates with the lower chamber. The tube 11 communicates with the tube body 1. The first elastic component includes a spring 6, a screw rod 3, a pressure plate 4, a baffle 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com