Compound abrasion-proof device for water wall of circulating fluidized bed boiler

A circulating fluidized bed and water wall technology, which is applied in the field of circulating fluidized bed boiler water wall compound anti-wear device, can solve the problem that it is difficult to meet the needs of long-term stable operation of the boiler, poor contact of anti-wear tile water wall tubes, boiler Efficiency reduction and other problems, to achieve the effect of reducing the shock effect, long-lasting anti-wear effect, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

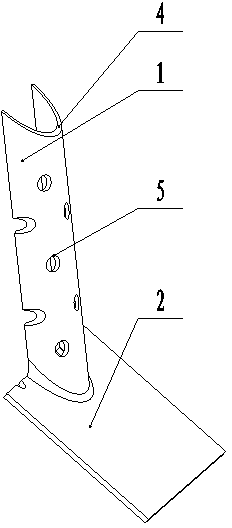

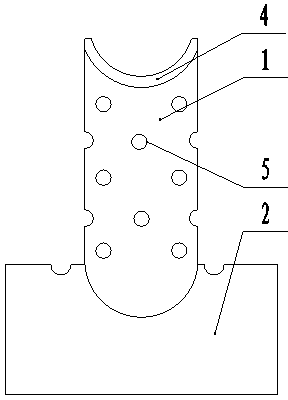

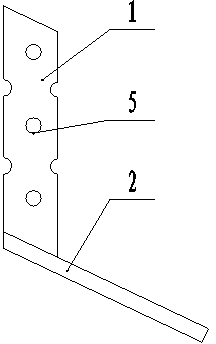

[0027] Such as figure 1 As shown in -4, the compound anti-wear device for the water wall of the circulating fluidized bed boiler of the present invention includes a wedge-shaped anti-wear protection tile 1 and a wing-shaped deflector 2. The wedge-shaped anti-wear protection tile 1 is placed vertically or obliquely, and the wedge-shaped The cross-section of the wear-resistant tile 1 is arc-shaped, and the wing-shaped deflector 2 is a square flat plate arranged obliquely downward. The wing-shaped deflector 2 is fixed on the bottom of the wedge-shaped wear-resistant tile 1, and the wing-shaped deflector 2, the part that is positioned at the inside of the arc of the wedge-shaped wear protection tile 1 is cut off to form a gap 3.

[0028] The top surface 4 of the wedge-shaped anti-wear protection tile 1 is an inclined surface, and the included angle between the top surface 4 and the horizontal plane is 30°-60°.

[0029] The included angle between the airfoil baffle 2 and the horiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com