Fin preventing frosting to be easy to drain water

An anti-frost and fin technology, which is applied in the field of fin structure, anti-frost and easy-to-drain fins, can solve the problems of condensed water accumulation and easy drainage, and achieve high heat exchange efficiency, good thermal conductivity, and simple structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

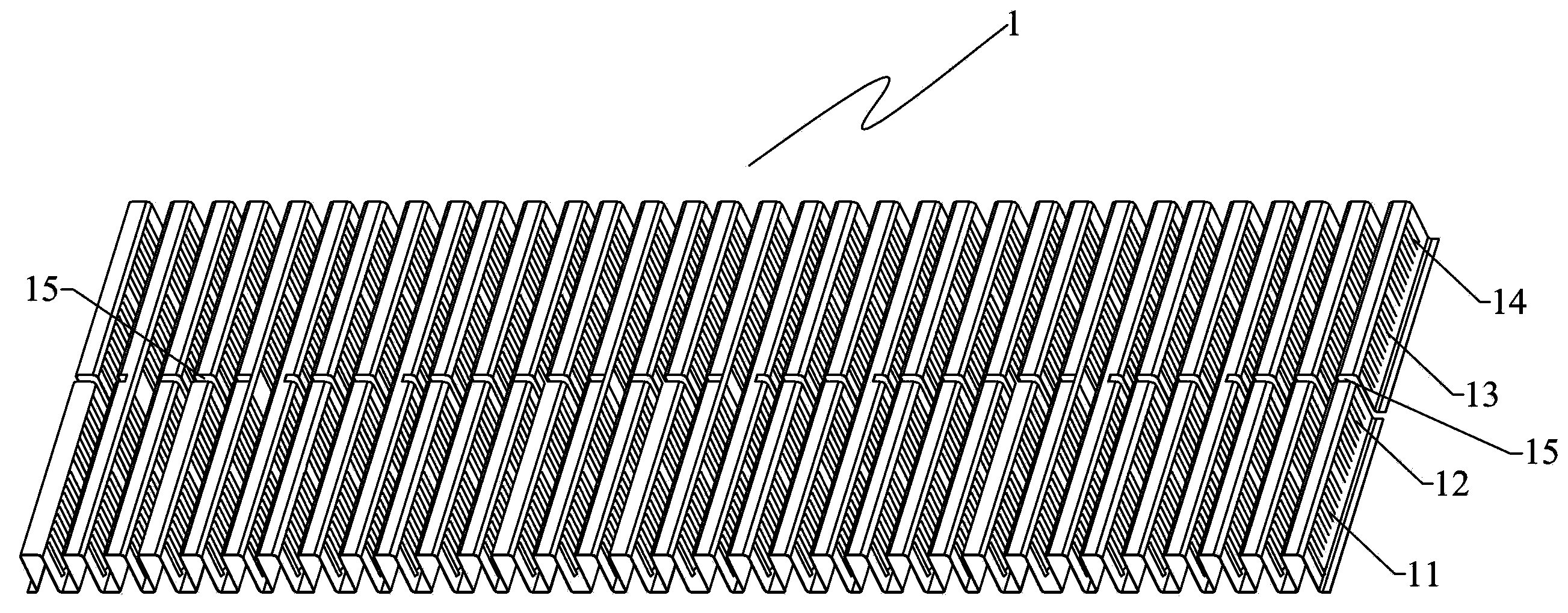

[0016] Such as figure 1 , 2 As shown, the anti-frost and easy-to-drain fin of the present invention includes a fin body 1, and the fin body 1 has a rectangular wave structure as a whole. The louver structures 11-14 are arranged at intervals, and the window opening angles of each louver structure 11-14 are consistent.

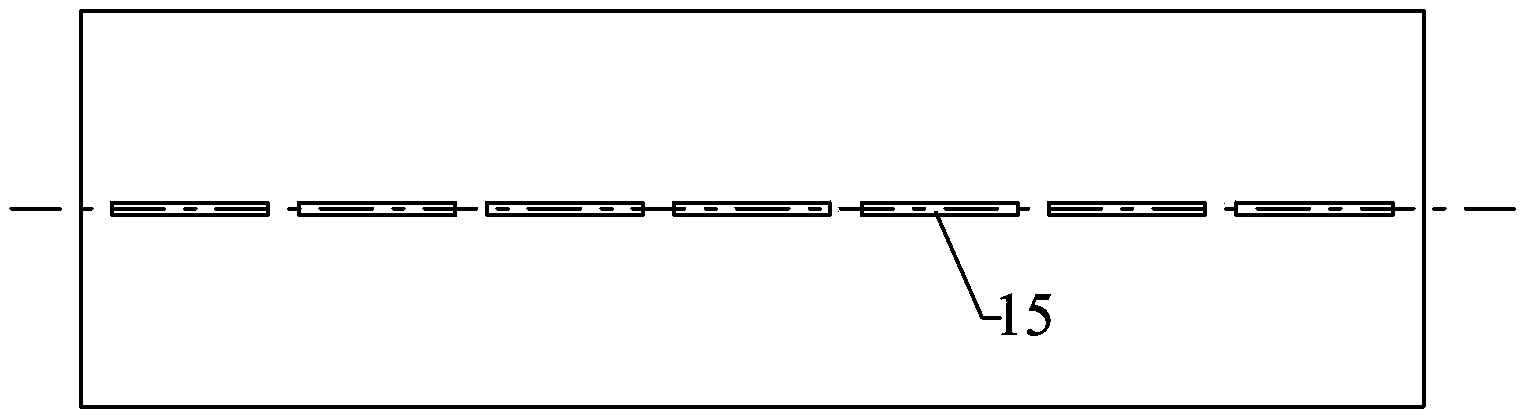

[0017] As a preferred solution of this embodiment, the fin body 1 is stamped from an integral metal plate (such as figure 2 As shown), the central axis of the fin body 1 is provided with slots 15 at intervals. The slots 15 can effectively solve the problem of condensed water accumulation and frosting, and improve heat exchange efficiency; further, the rectangular wave of the fin body 1 The pitch is 3-5 mm, the width is 38-60 mm, and the corner positions of the crest and trough form a rounded corner structure, which can effectively reduce stress concentration.

[0018] The present invention is not limited to the above-mentioned embodiments, if the various cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com