Comb type high molecular luminous material and its preparing method

A technology of polymer materials and molecules, which is applied in the field of comb-shaped polymer luminescent materials and its preparation, can solve problems such as poor luminous color purity and affecting luminous color purity and luminous efficiency, and achieve the goals of reducing energy transfer, solving accumulation, and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

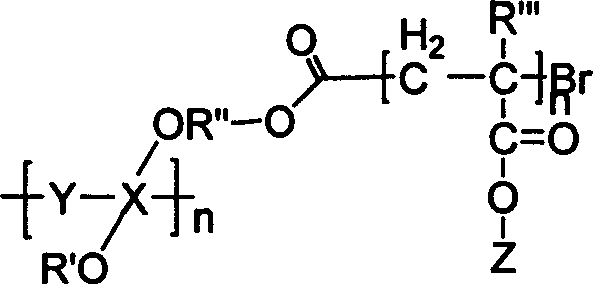

Method used

Image

Examples

Embodiment 1

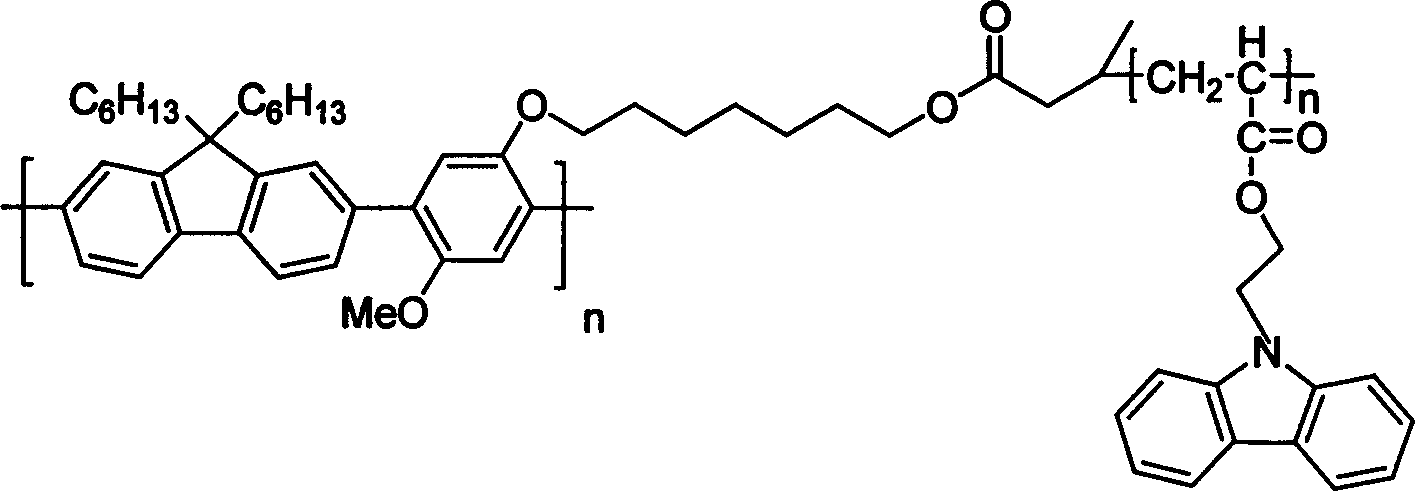

[0039] Embodiment 1, the preparation of light-emitting polymer containing carbazole

[0040] 1. Synthesis of 2,7-bisboronate-9,9'-dioctyl-fluorene monomer

[0041] Add 2,7-dibromofluorene 1 and a catalytic amount of tetrabutylammonium chloride into a 250ml double-necked bottle, seal it, and perform anhydrous and oxygen-free treatment. Then use a syringe to inject DMSO (dimethyl sulfoxide), heat and stir. Then inject 50% NaOH aqueous solution and heat to 80°C, the solution changes from a colorless transparent solution to a purple-red solution. After stirring for 5 minutes, 1-octyl bromide was injected. The mixture was kept under reflux at 80°C overnight, and a large amount of white solid precipitated out. Cool to room temperature, add HCl (2.0M) to adjust the pH value to neutral, the white solid disappears, and a large number of bubbles are generated. After the reaction is complete, add 100ml of dichloromethane for extraction, wash with saturated brine and wash with anhydro...

Embodiment 2

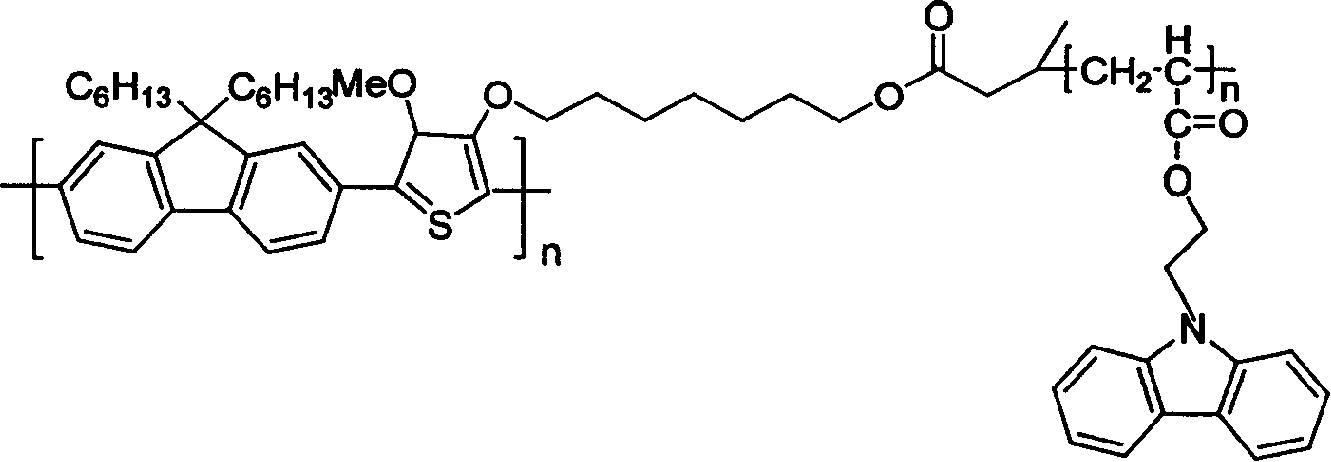

[0050] Embodiment 2, preparation containing quinoline light-emitting polymer

[0051] 1. Synthesis of 2,7-bisboronate-9,9'-dioctyl-fluorene monomer

[0052] Add 2,7-dibromofluorene 1 and a catalytic amount of tetrabutylammonium chloride into a 250ml double-necked bottle, seal it, and perform anhydrous and oxygen-free treatment. Then use a syringe to inject DMSO (dimethyl sulfoxide), heat and stir. Then inject 50% NaOH aqueous solution and heat to 80°C, the solution changes from a colorless transparent solution to a purple-red solution. After stirring for 5 minutes, 1-octyl bromide was injected. The mixture was kept under reflux at 80°C overnight, and a large amount of white solid precipitated out. Cool to room temperature, add HCl (2.0M) to adjust the pH value to neutral, the white solid disappears, and a large number of bubbles are generated. After the reaction is complete, add 100ml of dichloromethane for extraction, wash with saturated brine and wash with anhydrous MgSO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com