Calculating method of ultimate strength checking of connection of flange and bolt

A technology for connection bolts and ultimate strength, which is applied in the calculation field of flange connection bolt ultimate strength check, can solve problems such as the safety of fan connection bolt strength, achieve simple and easy calculation process, speed up calculation convergence speed, and improve calculation accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

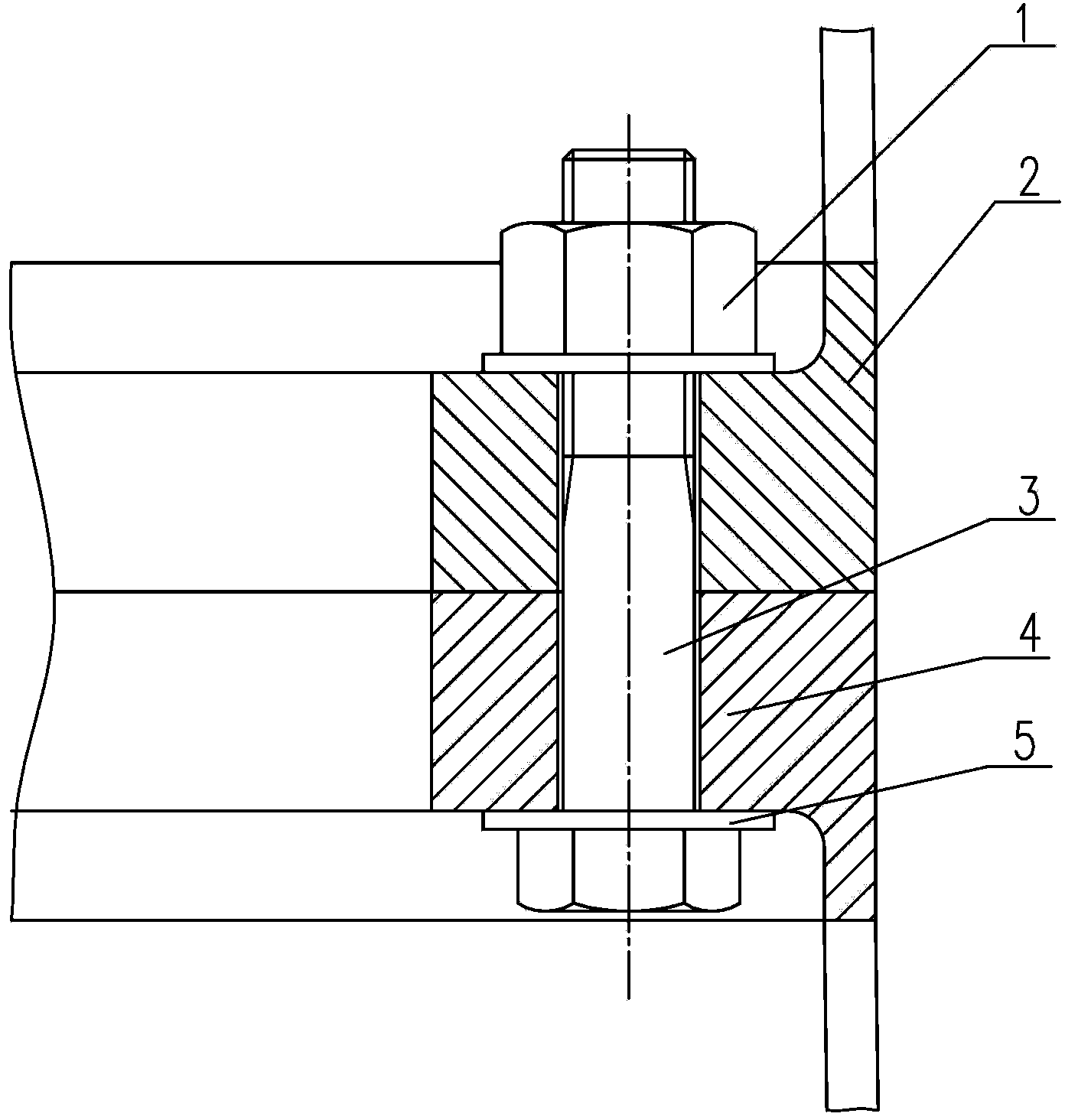

[0021] Embodiment: The calculation method of the present invention adopts ANSYS (finite element analysis software) as the implementation tool. This example uses the method of checking the ultimate strength of the flange connection bolts at the bottom of a fan tower for specific description. The flange connection structure is as follows: figure 1 As shown, its calculation method includes the following steps:

[0022] The first step: establish the geometric model of the flange bolt connection structure: use the solid model in ANSYS software to establish the upper and lower flanges 2 and 4, part of the tower structure, high-strength washer 5, nut 6 and nut 1 of high-strength bolts , where the upper and lower flanges 2, 4, and part of the tower structure form an integrated model; use line elements to build the screw rod 3 part of the high-strength bolt.

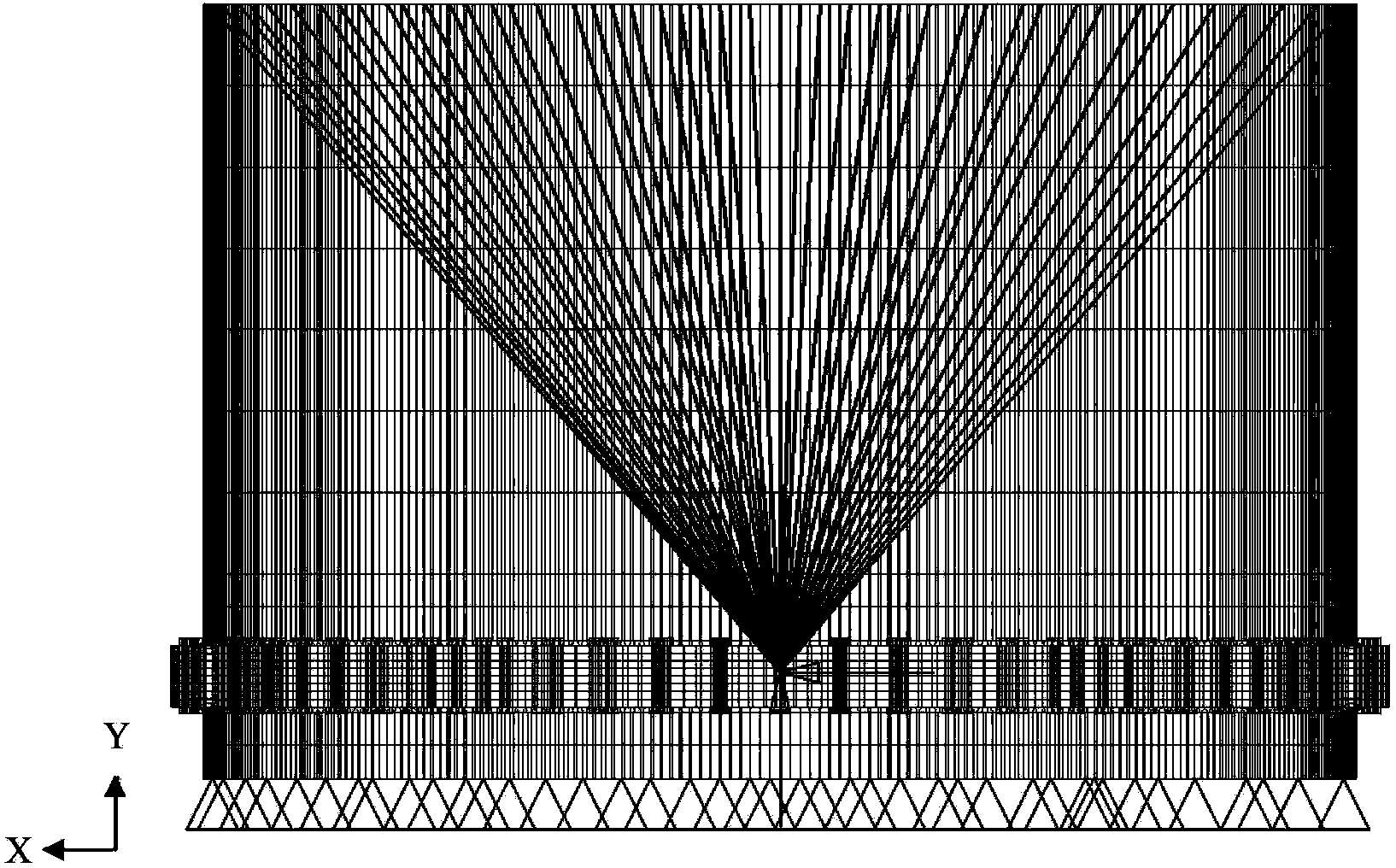

[0023] Step 2: Carry out finite element meshing for the geometric model of the flange bolted connection structure: see Table 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com