Polar plate weighing and matching method

A plate and grouping technology, applied in the direction of sustainable manufacturing/processing, climate sustainability, secondary battery manufacturing, etc., can solve the high scrap rate of a single plate, low production efficiency, and the weight of the plate group does not meet the requirements Requirements and other issues, to achieve the effect of improving the efficiency of matching, low scrap rate, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

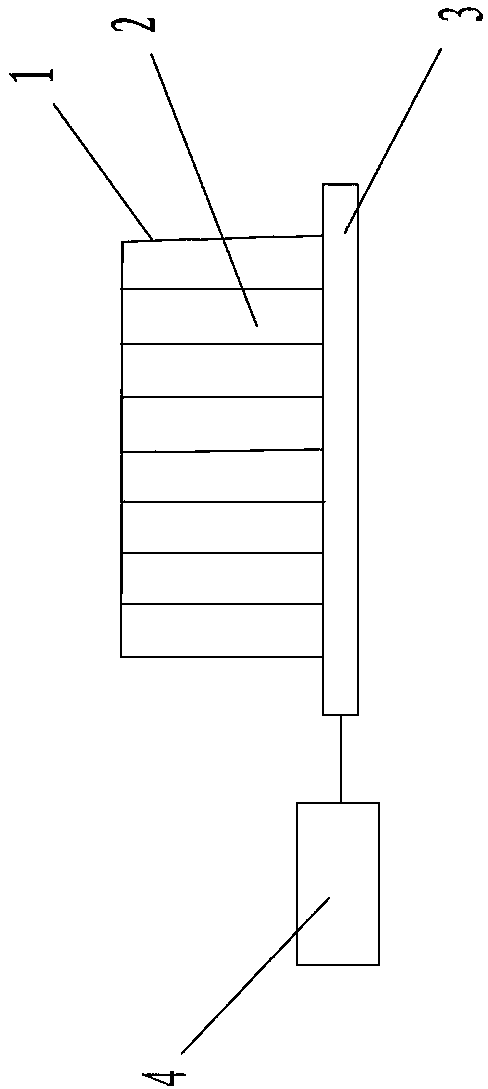

[0014] based on figure 1 As shown, the 4+4 pole plate method is used for grouping, and the steps are as follows: firstly, the pole plate unit composed of 8 troughs 2 is set to correspond to the 8 stations on the conveying mechanism 3. In the first step, several pole plates are placed into 8 material troughs 2, and one polar plate in material trough 2 is sequentially unloaded to the corresponding 8 stations by the reclaiming mechanism 1. At this time, the number of plates on No. 1 to No. 8 stations Each is 1 block. After the blanking process is completed, the conveying mechanism 3 will drive the plates on the 8 stations to move forward 2 stations, and then stop. The front No. 1 station and No. 2 station The pole plate is removed from the original station, the original No. 1 station and No. 2 station are replaced by the pole plate on the No. 3 station and No. 4 station, and the original No. 3 station and No. 4 station It is replaced by the plates on the No. 5 and No. 6 stations...

Embodiment 2

[0020] based on figure 1 As shown, the 4+3 pole plate method is used for grouping, and the steps are as follows: firstly, the pole plate unit composed of 7 troughs 2 is set to correspond to the 7 stations on the conveying device, and the first step is to put several pole plates into 7 In one material trough 2, one pole plate in the material trough 2 is sequentially unloaded to the corresponding seven stations by the reclaiming mechanism 1. The pole plate is moved forward by 2 stations as a whole, and then stops. The pole plates on the front No. 1 station and No. 2 station are moved out of the original station, and the original No. 1 station and No. 2 station It is replaced by the plates on the No. 3 and No. 4 stations. The original No. 3 and No. 4 stations are replaced by the plates on the No. 5 and No. 6 stations. The original No. 7 stations The pole plate on the position will move to the No. 5 station, and there is no pole plate on the No. 6 station and the No. 7 station at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com