Low-voltage complete set of reactive power compensation device

A low-voltage complete set, power compensation technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation, board/panel/desk of substation/switchgear, etc. Problems such as messy and disordered wiring, to achieve the effect of convenient maintenance and installation, easy maintenance and installation, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

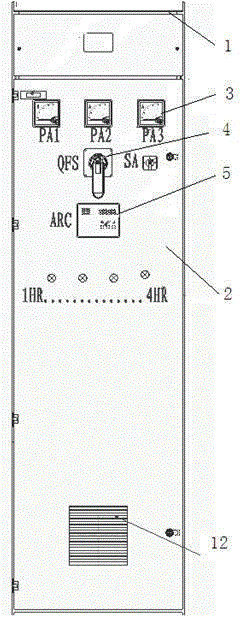

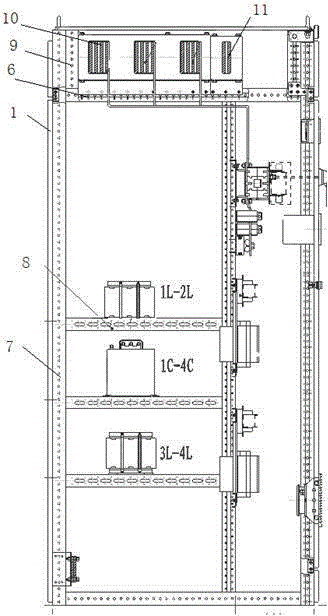

[0012] Such as Figure 1-2 As shown, the present invention includes:

[0013] Cabinet 1: a movable door 2 is set at the front end, and the isolating switch 3 of the fuse group, the universal transfer switch 4 and the power factor controller button 5 are arranged on the door, and a circuit breaker, a controller and more than one capacitor are arranged in the cabinet 1 Compensation circuit, the circuit breaker is connected to the power grid through copper bars, and its output terminals are respectively connected to each capacitance compensation circuit, the input terminal of the controller is connected to the power factor controller button, and the output terminal is connected to the switching switch. The fuses, switching switches and reactive power automatic compensation capacitors, the isolating switch of the fuse group are connected to the fuses;

[0014] Insulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com