Cooling-gas direct cooling process and device based on hot forming mould of boron steel plate

A technology of cooling gas and hot forming, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problem of dependent and limited heat transfer efficiency of die steel, and achieve the effect of high cooling efficiency and improving cooling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

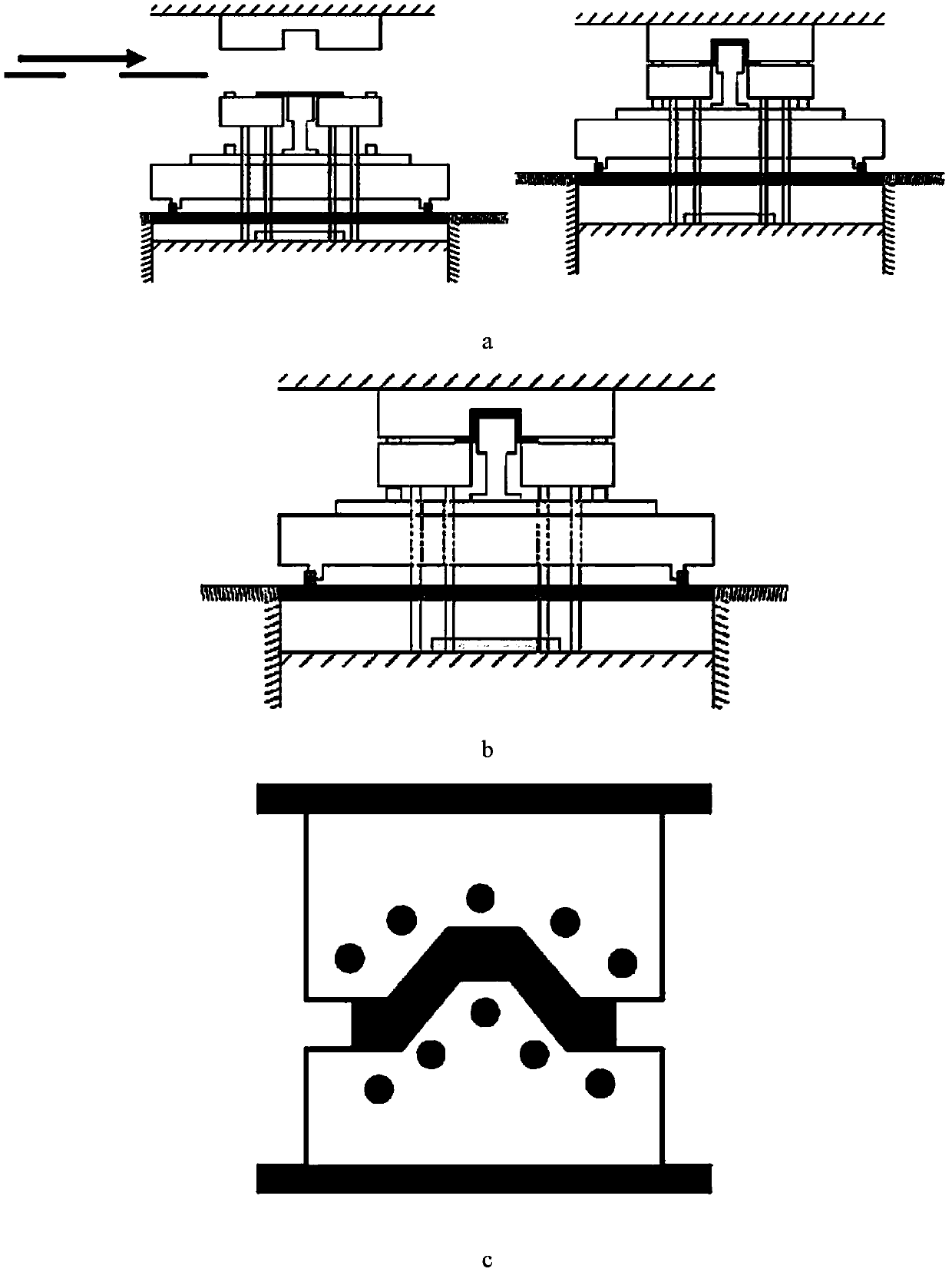

Method used

Image

Examples

Embodiment 1

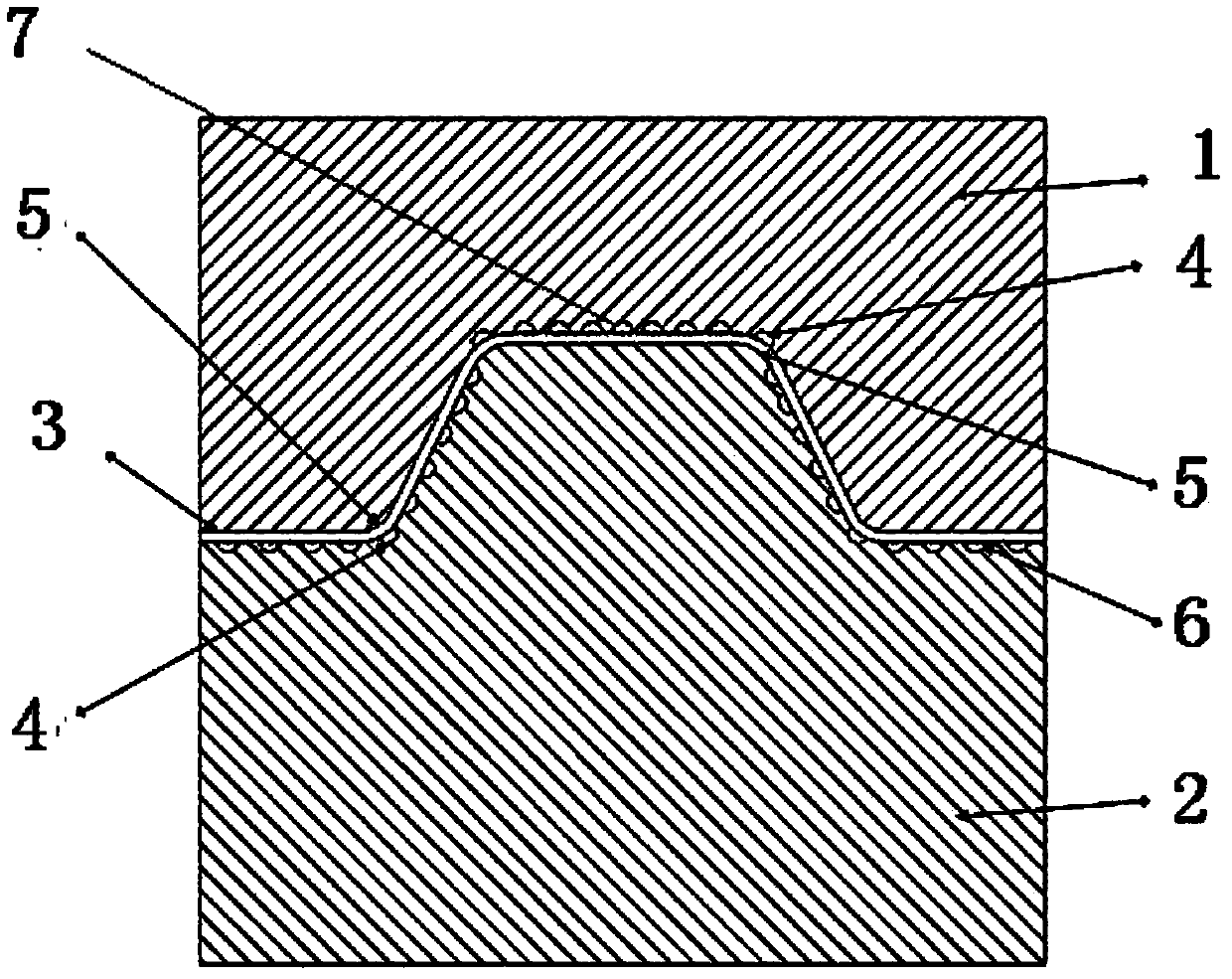

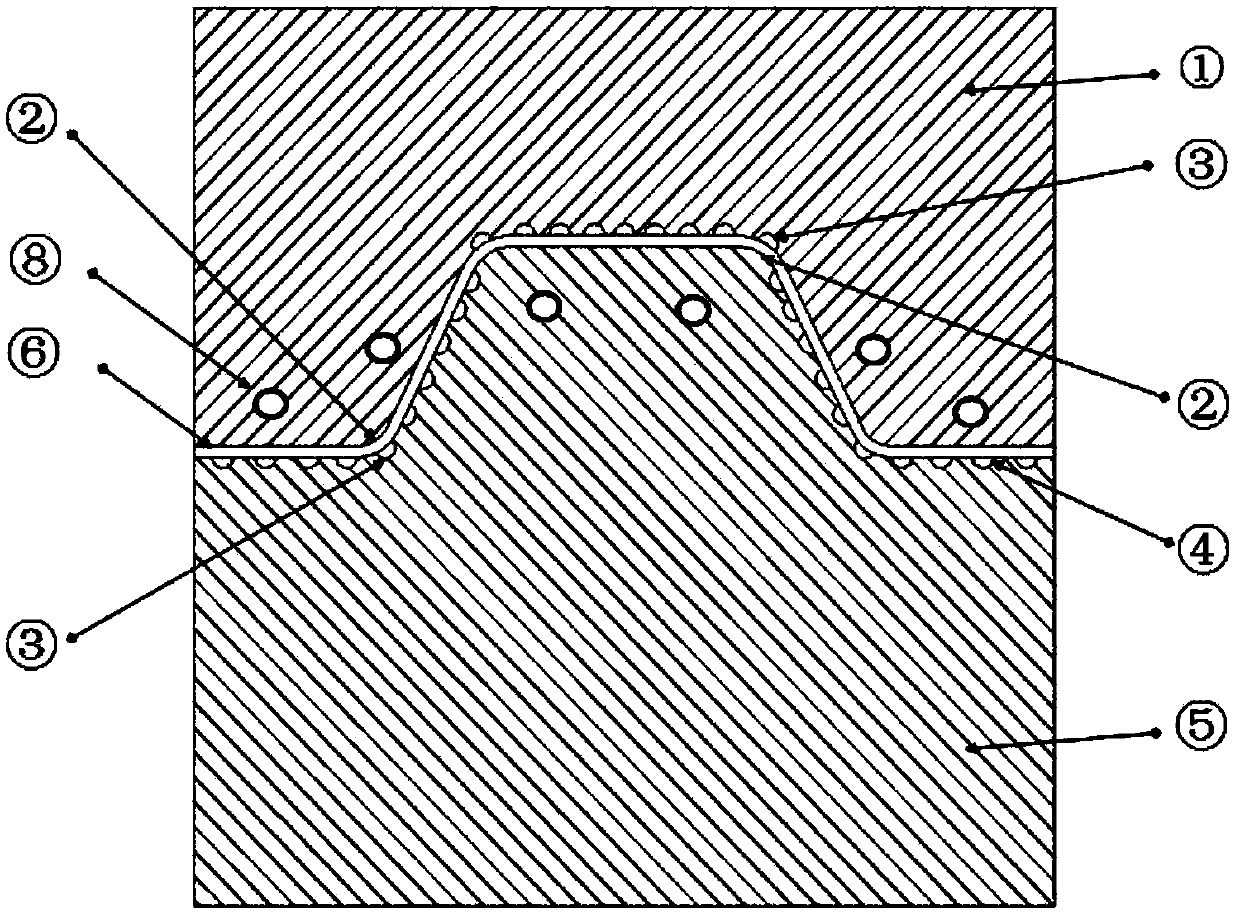

[0040] Such as figure 2 As shown, this embodiment includes: an upper mold 1 , a lower mold 2 and a semi-open cooling air channel 6 arranged on the contact surface of the upper mold 1 and the lower mold 2 . The cooling gas channels are unified into D6 semicircular grooves, and the distance between the centers of the grooves is uniformly 12mm. The press is a 150T special press for thermoforming, providing 4 sets of common industrial air-cooling air sources, the initial temperature of each set is -18C, the flow rate is 1000g / min, and the rated power is 7.5KW.

[0041] The workpiece is a 1.5mm thick boron steel plate with a length of 100mm and a section width of 150mm. The rounded corners are uniformly R9, and the draft angle is 60°C, that is, the arc length is 9.42mm.

[0042] Depending on the characteristics of the product workpiece 6, respective convex corners 2 and concave corners 3, as well as associated planar regions 4, are formed. During the high-temperature forming pro...

Embodiment 2

[0051] Such as figure 2 As shown, this embodiment includes: an upper mold 1 , a lower mold 2 and a semi-open cooling air channel 6 arranged on the contact surface of the upper mold 1 and the lower mold 2 . The cooling gas channels are unified into D6 semicircular grooves, and the distance between the centers of the grooves is uniformly 12mm. The press is a 150T special press for thermoforming, providing 8 sets of common industrial air-cooling air sources, the initial temperature of each set is -18C, the flow rate is 1000g / min, and the rated power is 7.5KW.

[0052] The workpiece is a 1.5mm thick boron steel plate with a length of 200mm and a section width of 150mm. The rounded corners are uniformly R6, and the draft angle is 60°C, that is, the arc length is 6.28mm.

[0053] Depending on the characteristics of the product workpiece 6, respective convex corners 2 and concave corners 3, as well as associated planar regions 4, are formed. During the high-temperature forming pro...

Embodiment 3

[0062] Such as figure 2 As shown, this embodiment includes: an upper mold 1 , a lower mold 2 and a semi-open cooling air channel 6 arranged on the contact surface of the upper mold 1 and the lower mold 2 . The cooling gas channels are uniformly formed as 3mm wide and 9mm deep rectangular grooves, and the groove spacing is uniformly 12mm. The press is a 150T special press for thermoforming, providing 6 sets of common industrial air-cooling air sources, the initial temperature of each set is -18C, the flow rate is 1000g / min, and the rated power is 7.5KW.

[0063] The workpiece is a 2.5mm thick boron steel plate with a length of 100mm and a section width of 150mm. The rounded corners are uniformly R6, and the draft angle is 30°C, that is, the arc length is 3.14mm.

[0064] Depending on the characteristics of the product workpiece 6, respective convex corners 2 and concave corners 3, as well as associated regions 4, are formed. During the high-temperature forming process, due t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com