Cold rolling measuring and controlling device for workblank of bearing ring

A technology of bearing rings and measurement and control devices, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of low measurement efficiency and measurement accuracy, and achieve the effects of easy analysis and calculation, simple structure, and high measurement and control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

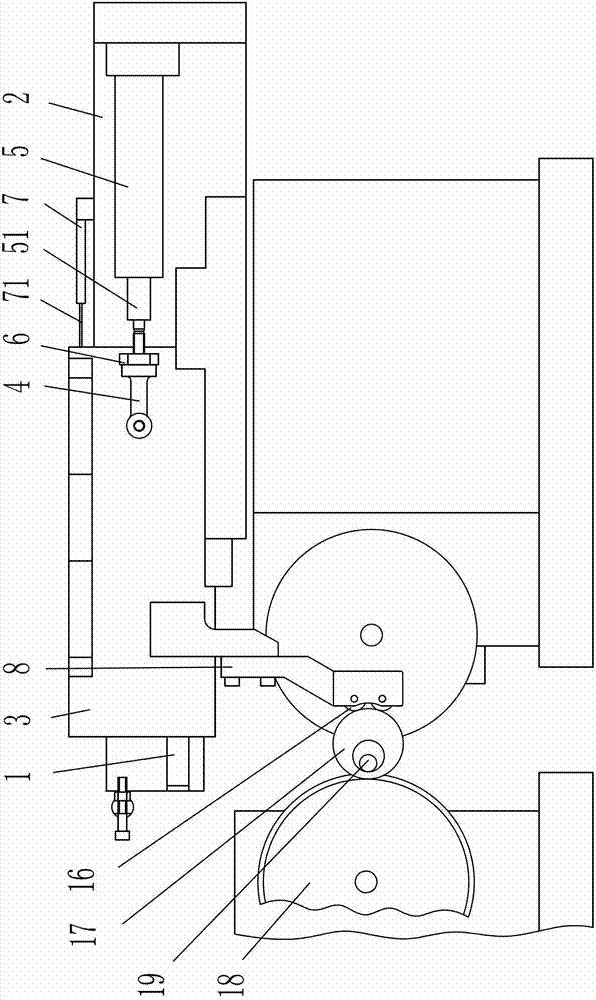

[0020] Embodiment 1, as attached figure 1 Shown: a bearing ring blank cold rolling measurement and control device, including a fixed seat 2, a sliding seat 3 connected to the fixed seat 2 through a transverse slide rail 1, a measuring head fixedly connected to the sliding seat 3, and driving the measuring head to collide with the bearing sleeve The interference mechanism and the measuring and controlling device of the outer circumference of the ring blank 17. The transverse slide rail 1 is a dovetail slide rail.

[0021] The interference mechanism includes a connecting rod 4 hinged with the sliding seat 3 through a hinge shaft, an oil cylinder 5 whose axis is parallel to the transverse slide rail 1 and screwed to the fixed seat 2, a universal joint 6 or a floating joint; in this embodiment, The cylinder rod 51 of the oil cylinder 5 is connected with the connecting rod 4 through the universal joint 6 .

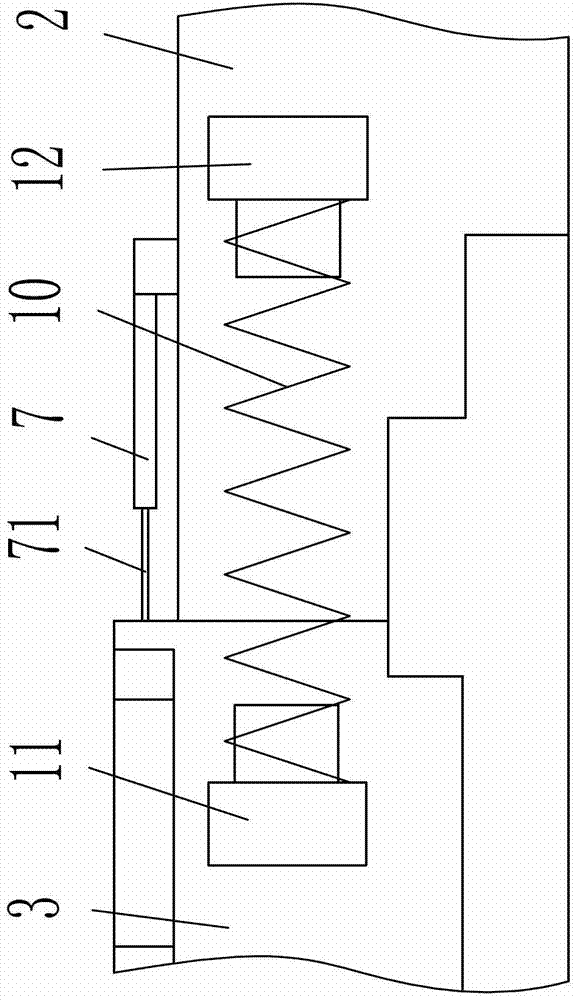

[0022] Described measuring and controlling device is the first displacem...

Embodiment 2

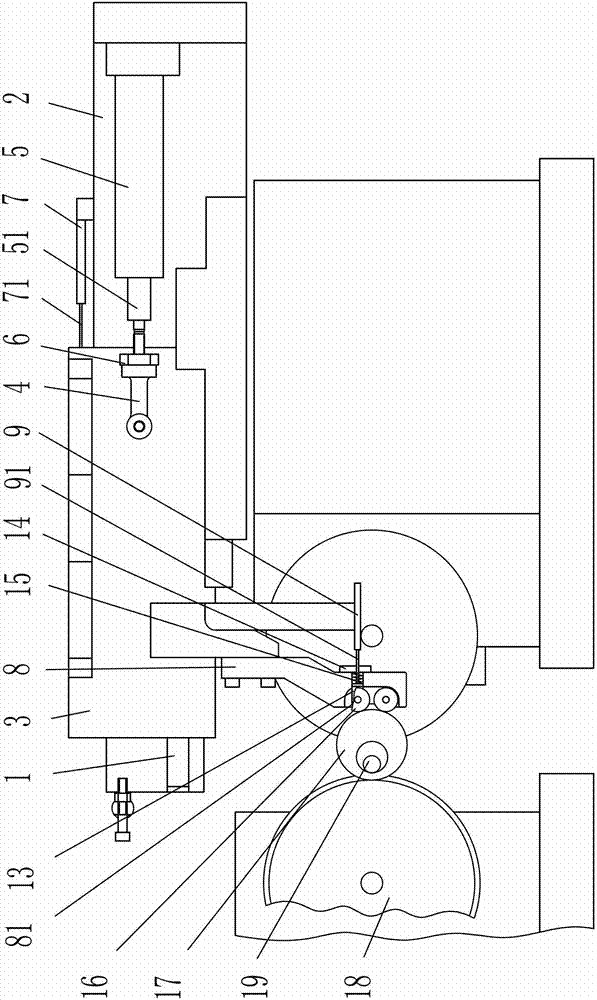

[0028] Embodiment 2, as attached figure 2 Shown: a bearing ring blank cold rolling measurement and control device, including a fixed seat 2, a sliding seat 3 connected to the fixed seat 2 through a transverse slide rail 1, a measuring head fixedly connected to the sliding seat 3, and driving the measuring head to collide with the bearing sleeve The interference mechanism and the measuring and controlling device of the outer circumference of the circle blank 17. The transverse slide rail 1 is a dovetail slide rail.

[0029] The interference mechanism includes a connecting rod 4 hinged with the sliding seat 3 through a hinge shaft, an oil cylinder 5 whose axis is parallel to the transverse slide rail 1 and screwed to the fixed seat 2, a universal joint 6 or a floating joint; in this embodiment, The cylinder rod 51 of the oil cylinder 5 is connected with the connecting rod 4 through the universal joint 6 .

[0030] Described measuring and controlling device is the first displa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com