Correcting device before disc shear of stretch-bending straightening machine

A technology of stretch-bending straightening and disc shearing, applied in shearing devices, accessories of shearing machines, metal processing equipment, etc. , Affect the quality of finished products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

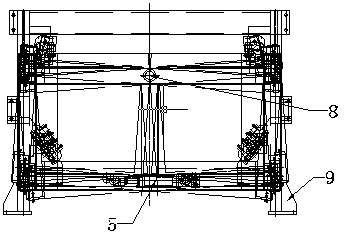

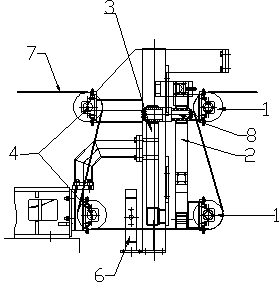

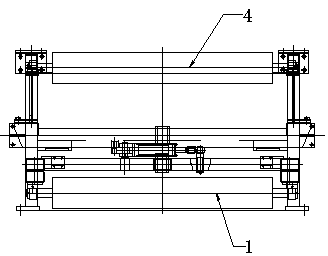

[0014] Below in conjunction with accompanying drawing and specific embodiment, to the present invention figure 1 Further details will be given for the pre-shear correction device of the tension bending straightening machine disc of the present invention.

[0015] As shown in the figure, the disc shearing correction device of the tension straightening machine of the present invention includes a frame 9, on which a fixed frame 3 is arranged, and the rear of the fixed frame 3 is provided with a Position-shifting centering detection device 6, fixed frame 3 is equipped with a pair of fixed rollers 4 that can be guided and aligned to ensure that the belt exit is at the elevation of the rolling line; fixed frame 3 is equipped with a swing frame through a hinge shaft 8 2. A pair of swing rollers 1 are installed on the swing frame 2, and a hydraulic cylinder 5 that can drive the swing frame 2 to swing along the hinge shaft 8 is installed between the swing frame 2 and the fixed frame 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com