Small bi-functional special type micro processing machine tool

A micro-fabrication, dual-function technology, applied in electric machining equipment, metal machining equipment, manufacturing tools, etc., to achieve the effects of high precision, improved machining accuracy, and improved machining flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

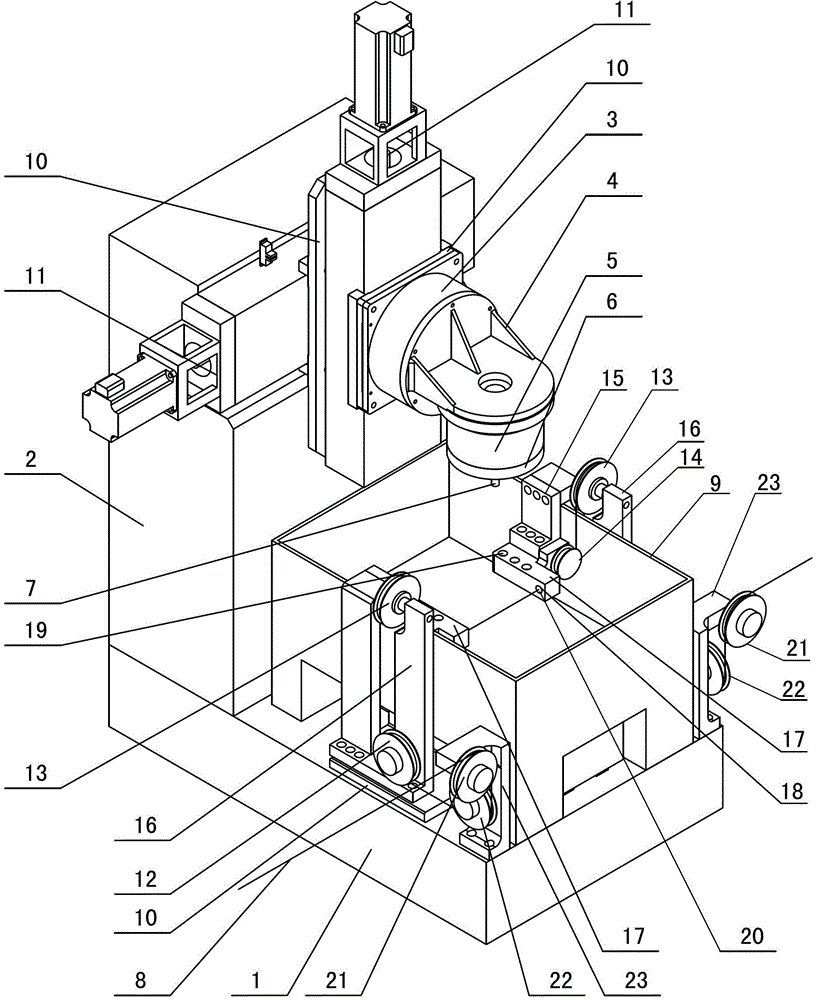

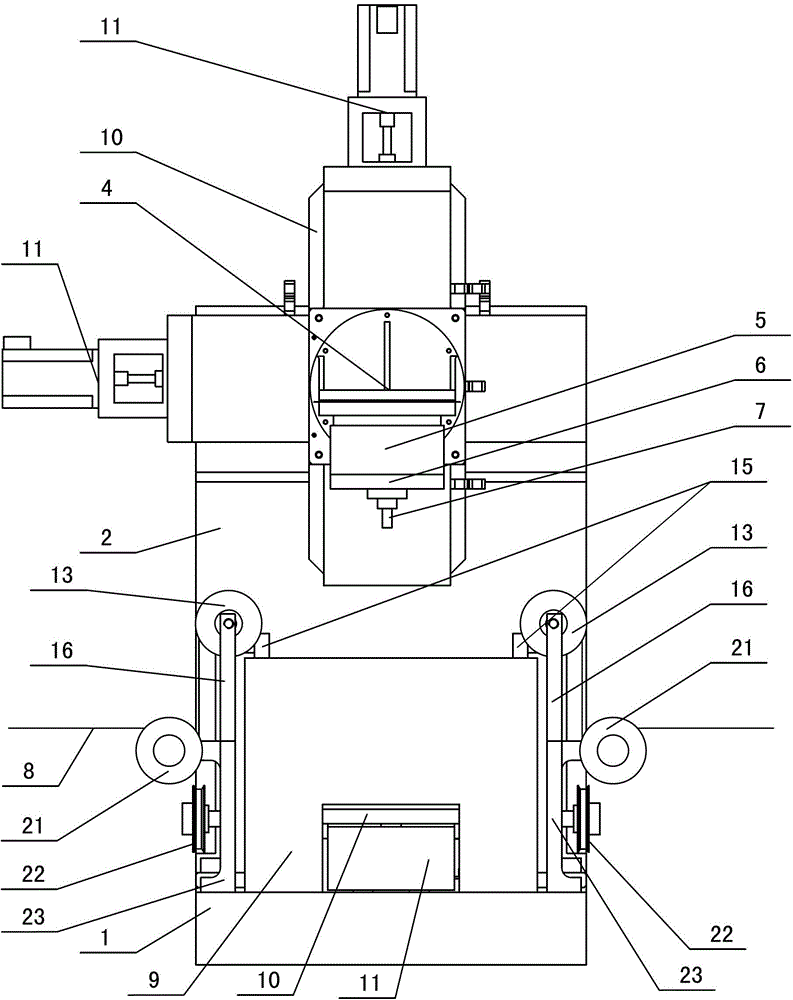

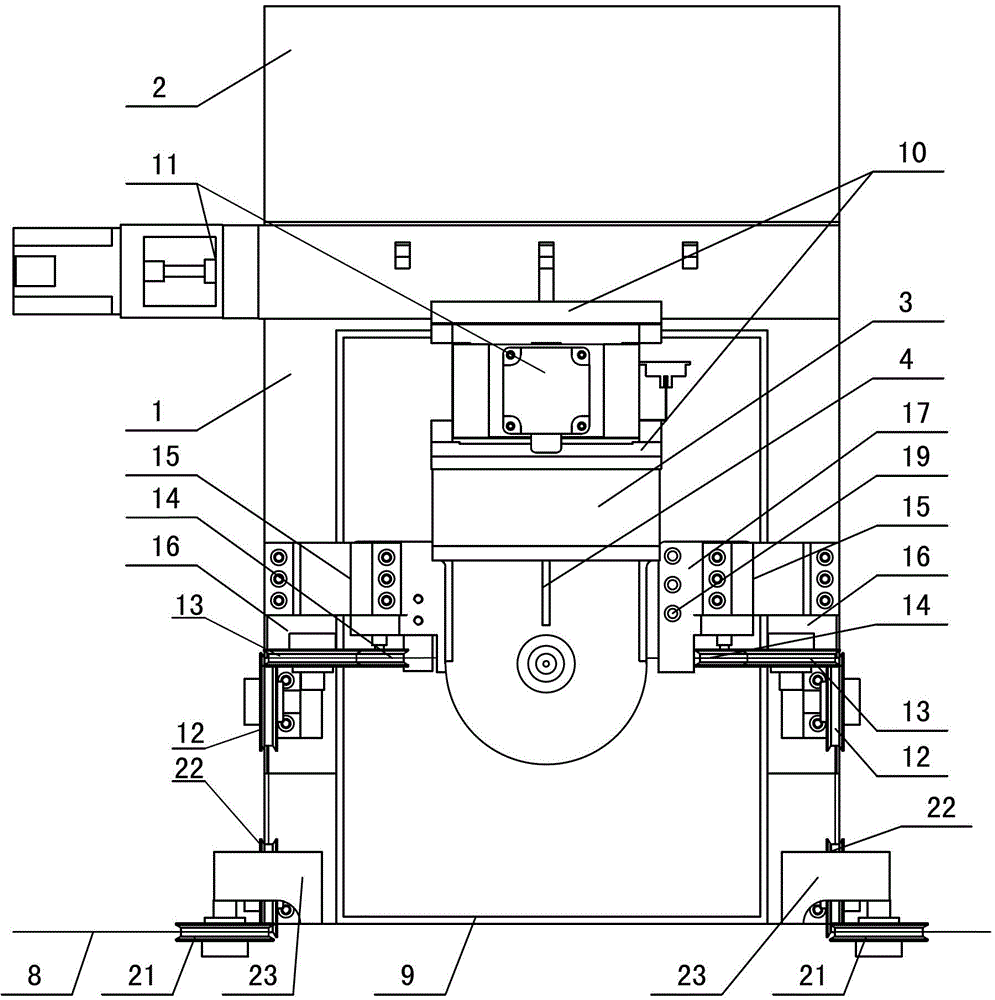

[0017] exist Figure 1-4 In the shown embodiment: including bed 1, column 2, X-axis motion assembly, Y-axis motion assembly, Z-axis motion assembly, B-axis 3, support 4, C-axis 5, fixture 6, electrode 7, electrode wire 8. The fixed wire wheel group, the moving wire wheel group and the working fluid box 9, wherein, the B-axis 3 and the C-axis 5 both adopt a direct-drive rotary motor, and the X-axis motion component, the Y-axis motion component and the Z-axis motion component The structure is the same, both include a moving slide 10 and a driving device 11, and the driving device 11 adopts a linear servo motor; taking the X-axis moving assembly as an example, the moving sliding table 10 is supported on the driving device 11, and is dragged by the driving device 11 along the X axis. Linear movement in the axial direction; the X-axis motion component is fixedly installed on the column 2, the Z-axis motion component is fixedly mounted on the motion slide table 10 of the X-axis moti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com