Universal grinding device for ball core of special coal chemical ball valve for drill lathe

A universal grinding and coal chemical technology, applied in the direction of grinding/polishing equipment, grinding machines, manufacturing tools, etc., can solve the problems that cannot be processed, high-hardness ball cores cannot meet the production requirements, etc., and achieve the effect of satisfying the processing size accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

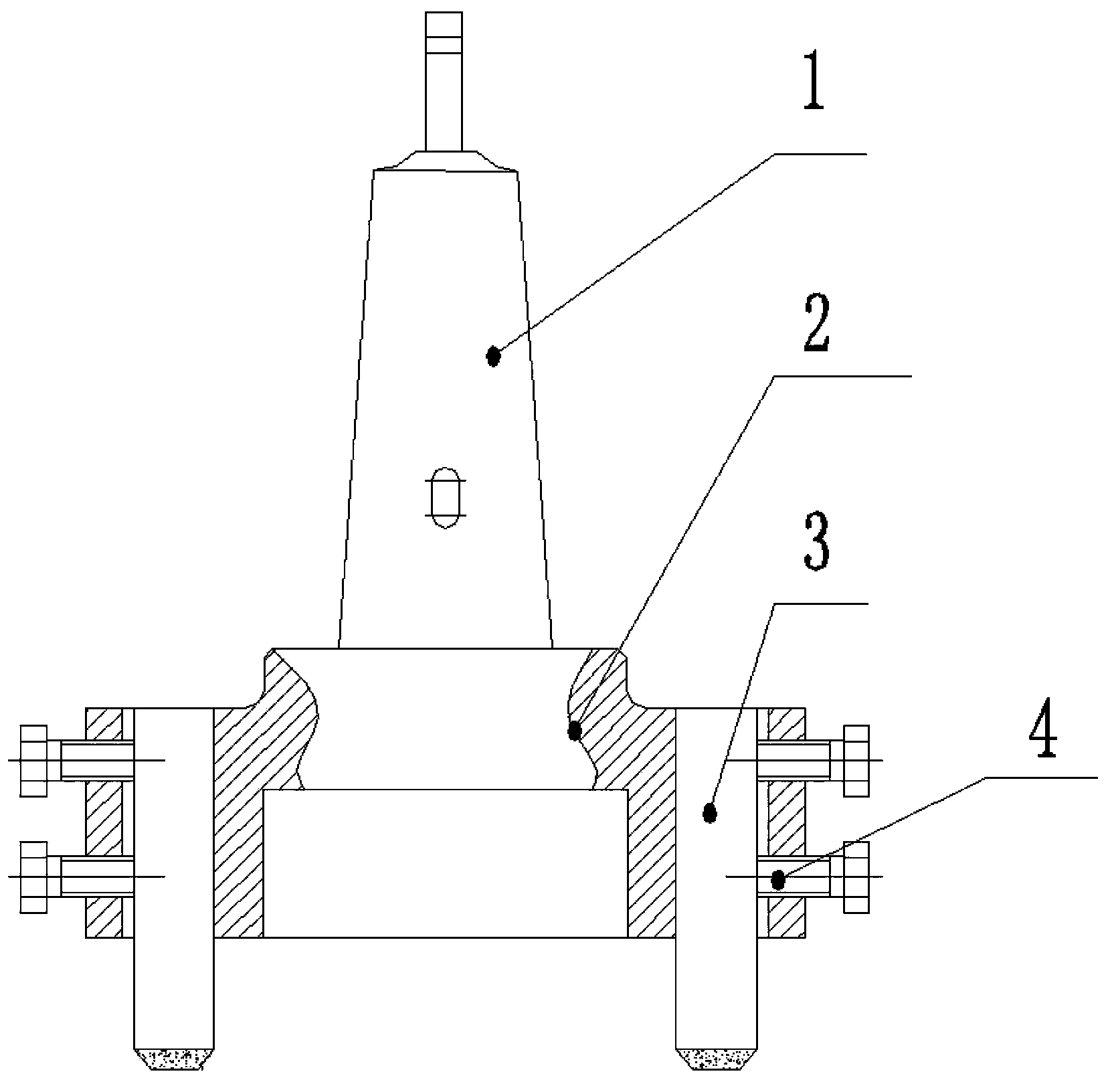

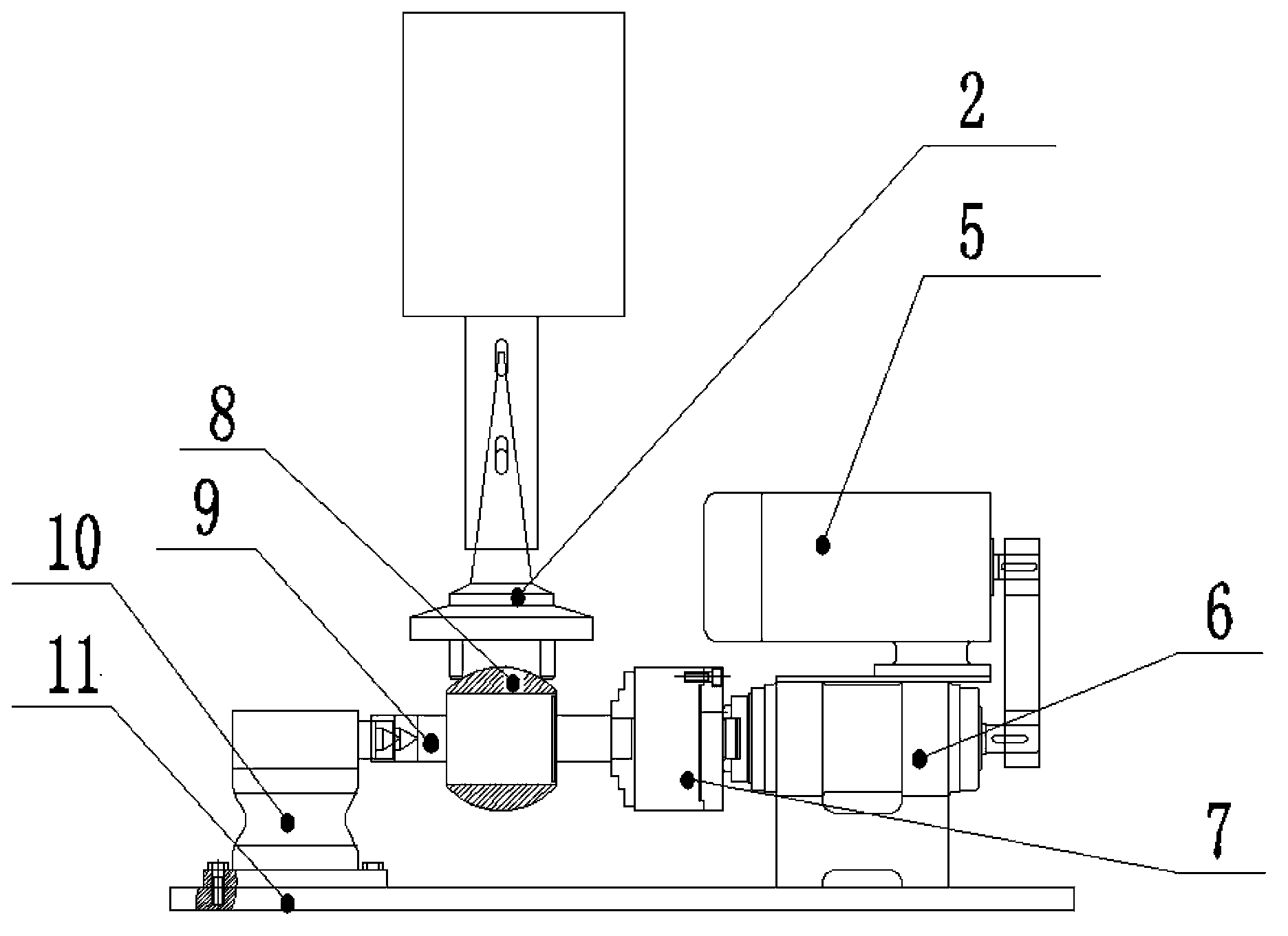

[0011] Such as figure 1 , 2 As shown, the present invention is a kind of universal grinding device for coal chemical ball valve ball core, which is specially used for drilling machine. , grinding sand bars 3 are installed in each grinding tank. It also includes a workbench 11 on which the rotating shaft 6 is mounted. Support is installed on workbench 8 in addition, and this rotating shaft 3 then is installed on this support, rotating shaft 3 comprises housing, axle, bearing, and belt pulley can be installed at one end, and three claws can be installed at the other end. Specifically, one end of the rotating shaft 6 is connected with the external motor 5 through a transmission mechanism, such as a belt transmission mode, and the other end is fixedly connected with the three claws 7, and a tailstock is also installed on the workbench 11 next to the rotating shaft 6. 10, a top end is installed on the tailstock 10 .

[0012] Wherein at least 2 fastening screws 4 are installed o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap