Adjustable valve key

An adjustable wrench technology, applied to wrenches, manufacturing tools, wrenches, etc., can solve the problems of time-consuming and laborious opening and closing, low work efficiency, and unsatisfactory operators, and achieve the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

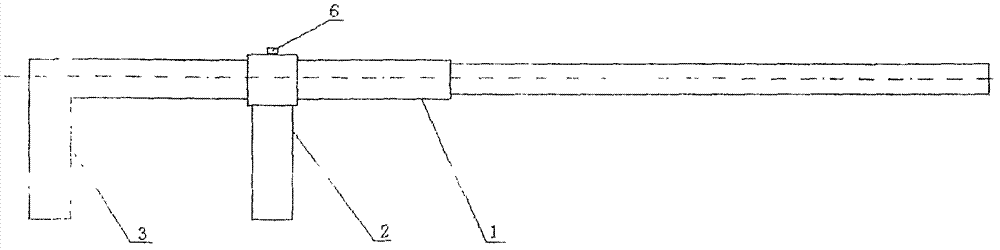

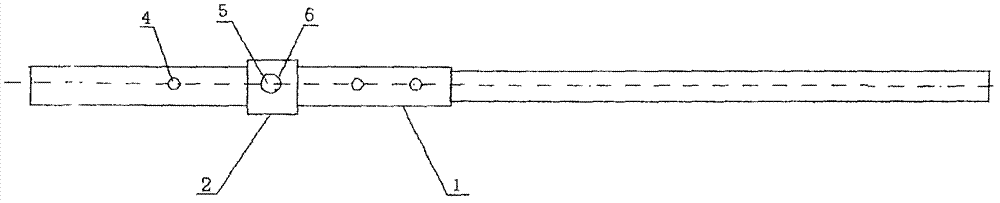

[0017] see figure 1 and figure 2 , the wrench body 1 is provided with a wrench front claw 3 and a wrench rear claw 2, the wrench front claw 3 is located at the end of the wrench body 1 and is integrated with the wrench body 1, and the wrench rear claw 2 can move along the wrench body 1 Move back and forth in the axial direction, four positioning holes 4 are provided on the wrench body 1, and a fixing hole 5 is provided on the corresponding position of the rear paw 2 of the wrench. on body 1. When in use, for valves of different specifications, adjust the rear claw 2 to a position suitable for the corresponding valve specification, and then use the bolt 6 to fix the rear claw 2 on the wrench body 1 .

Embodiment 2

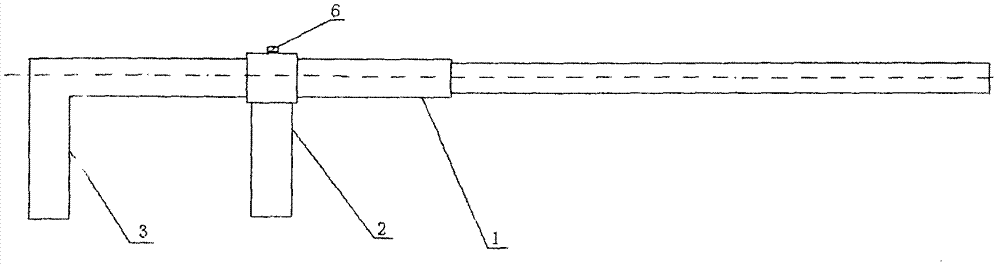

[0019] see image 3 , Figure 4 and Figure 5 The wrench body 1 is provided with two wrench front claws 3 and a wrench rear claw 2. The wrench front claws 3 are arranged on both sides of the end of the wrench body 1 and are integrated with the wrench body 1. The wrench rear claw 2 can move along the wrench body 1 axis. Move forward and backward, there are four positioning holes 4 on the wrench body 1, and there is a fixing hole 5 on the corresponding position of the wrench rear claw 2, and the bolt 6 passes through the positioning holes 4 and fixing holes 5 to fix the wrench rear claw 2 on the wrench body 1 on.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com