Seat shock-absorbing device on motor vehicle

A shock absorbing device, a technology for motor vehicles, applied in the direction of seat suspension devices, etc., can solve the problems of increasing driver fatigue, driver discomfort, affecting the driver's work, etc., achieving good shock absorbing effect, ensuring safety, seat smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

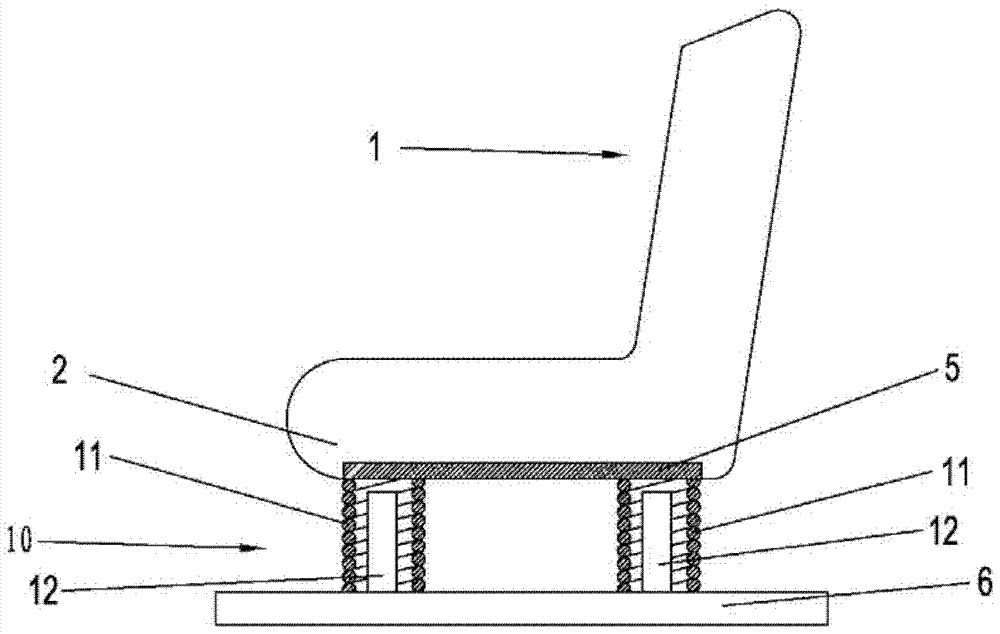

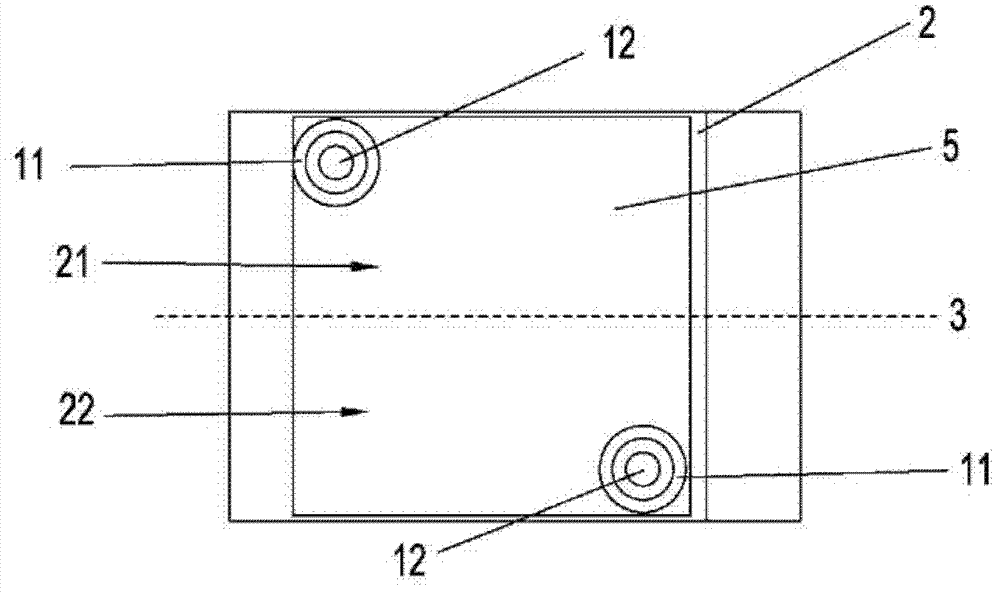

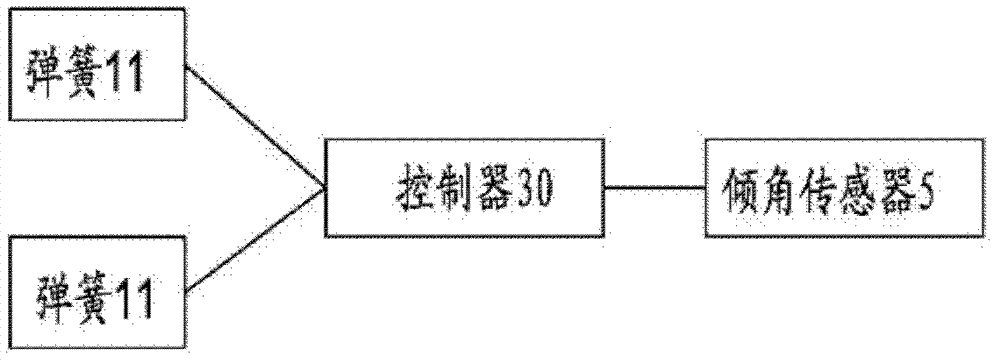

[0033] Such as figure 1 , figure 2 , image 3 As shown, in the present embodiment, the mechanical spring type electromagnetic damper 10 includes two springs 11, and the bottom 2 of the seat 1 in the cab of the motor vehicle is divided into the first area 21 and the second area 21 with the same area by the first central axis 3. In the second area 22, respective one ends of the two springs 11 are respectively fixed in the first area 21 and in the second area 22, and the other ends of the two springs 11 are respectively fixed on the base plate 6 of the cab of the motor vehicle, and the two springs 11 Magnetic cores 12 are respectively arranged inside, and the two springs 11 are respectively electrically connected to the controller 30, and the controller 30 controls the stiffness of the two springs 11 by controlling the current intensity of the two springs 11 respectively according to the electrical signal of the inclination sensor.

Embodiment 2

[0035] Such as Figure 4 , Figure 5 , Figure 6 As shown, in the present embodiment, the mechanical spring type electromagnetic damper 10 includes four springs 41, 42, 43, 44, and the bottom 2 of the seat 1 of the driver's cab of the motor vehicle is defined by the first central axis 3 and the first central axis. The second central axis 4 perpendicular to the axis 3 is divided into four areas 9 with equal areas, and the respective one ends of the four springs 41, 42, 43, 44 are respectively fixed in the four areas 9, and the four springs 41, 42, 43, The other ends of 44 are respectively fixed on the bottom plate 6 of the cab of the motor vehicle, and the insides of the four springs 41, 42, 43, 44 are respectively provided with magnetic cores 12. The four springs 41, 42, 43, 44 are electrically connected with the controller 30 respectively, and the controller 30 controls the current intensity of the four springs 41, 42, 43, 44 according to the electric signal of the inclinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com