Device and method for stopping roller bed transmission

A technology of blocking device and roller table, which is applied in the direction of roller table, conveyor objects, transportation and packaging, etc., can solve the problems of workers' work distraction, product quality impact, object collision, etc., and achieves convenient operation, wide application range, Ease of installation and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

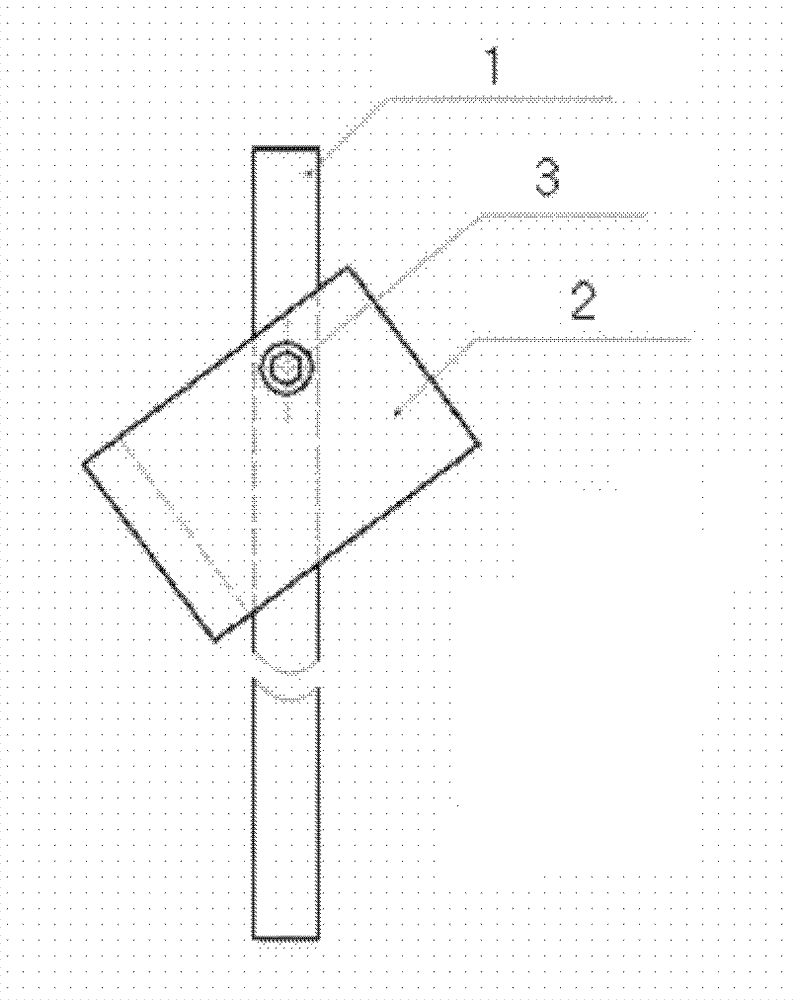

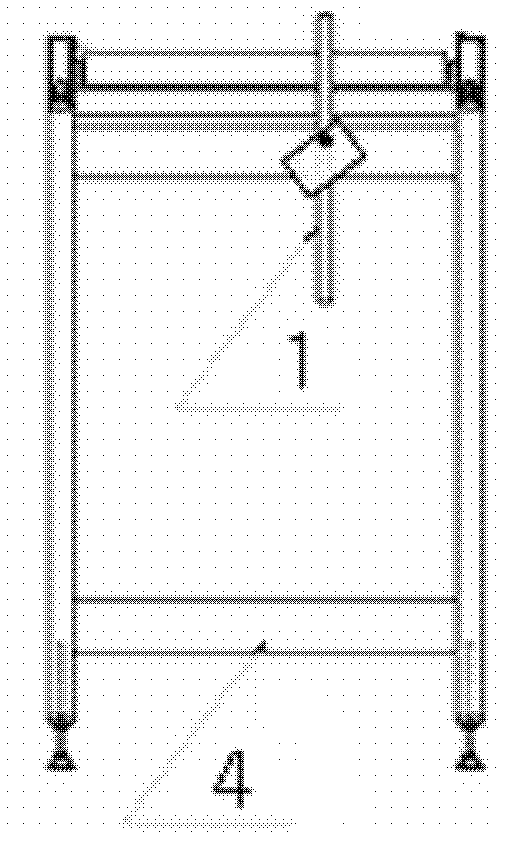

[0025] Device embodiment

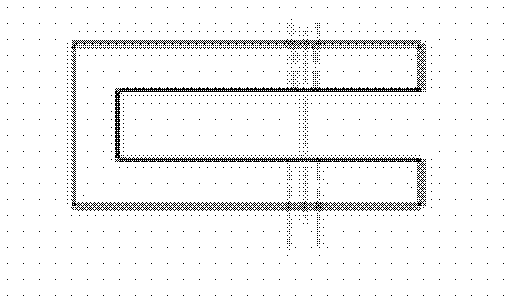

[0026] A roller conveyor blocking device, such as Figures 1 to 4 As shown, it includes a material blocking rod 1 and a limit plate 2. The material blocking rod 1 is arranged above the roller 4 in the roller table, and is connected to the support of the roller table through a connection point. The rotation direction of the material blocking rod 1 is up and down. rotate. The limiting plate 2 is connected to the lower half of the material-resistance rod 1, and as the material-resistance rod 1 rotates downward to image 3 In the shown position, the limiting plate 2 will block the transmission of parts. A screw rod 3 whose specification is M12 is fastened between the limiting plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com