Method and unit for feeding beads

A technology of beads and guide plates, applied in applications, food science, conveyor objects, etc., can solve problems such as requiring too much space and complex component structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

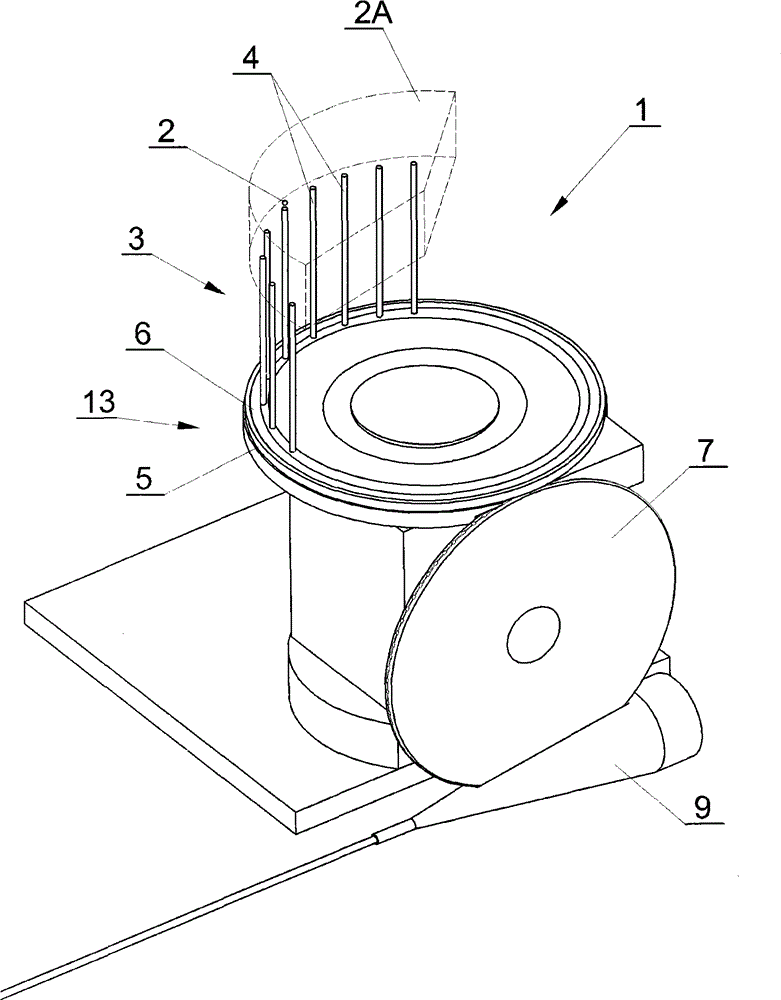

[0024] figure 1 A feeder 1 for beads 2 is shown. The feeder is provided with a storage container 2A for beads 2, a bead stream supply unit 3, and a unit 13 for conveying beads to a transfer wheel. And a transfer wheel 7 that transfers the beads 2 into the filter material that is transferred along the funnel 9. For the sake of brevity, the elements that fasten each unit are not shown.

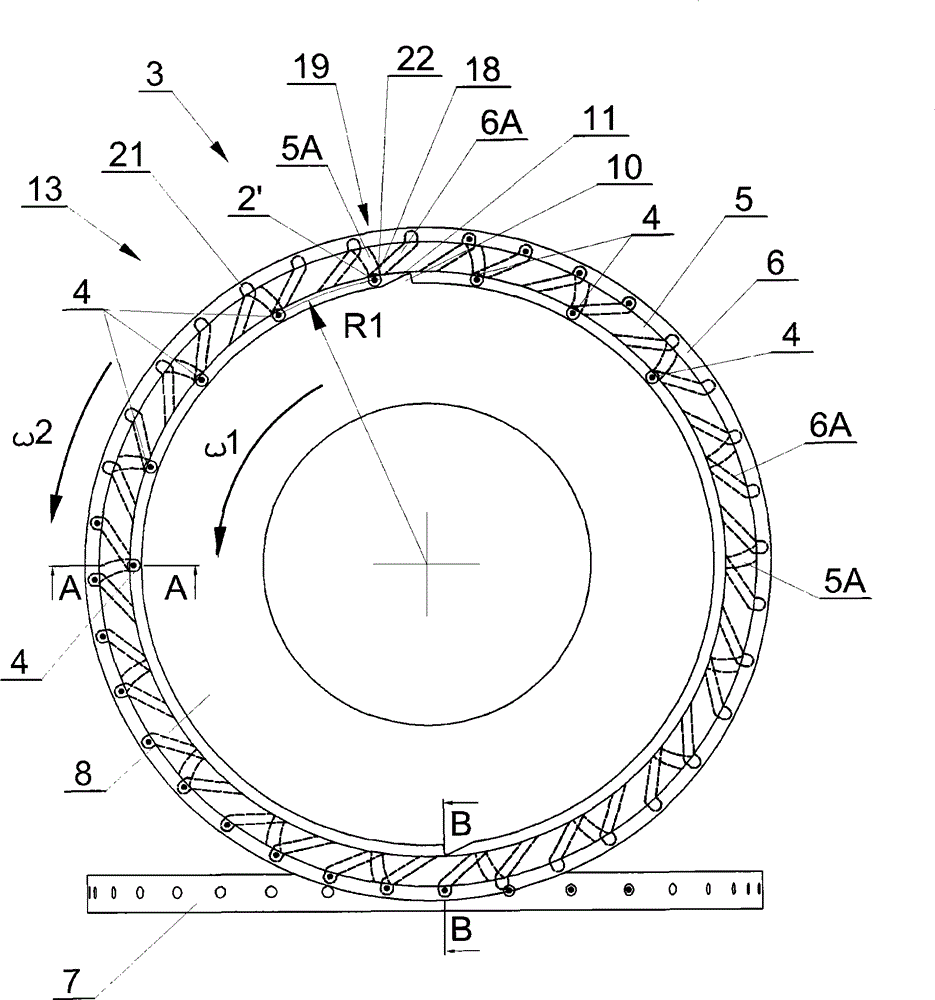

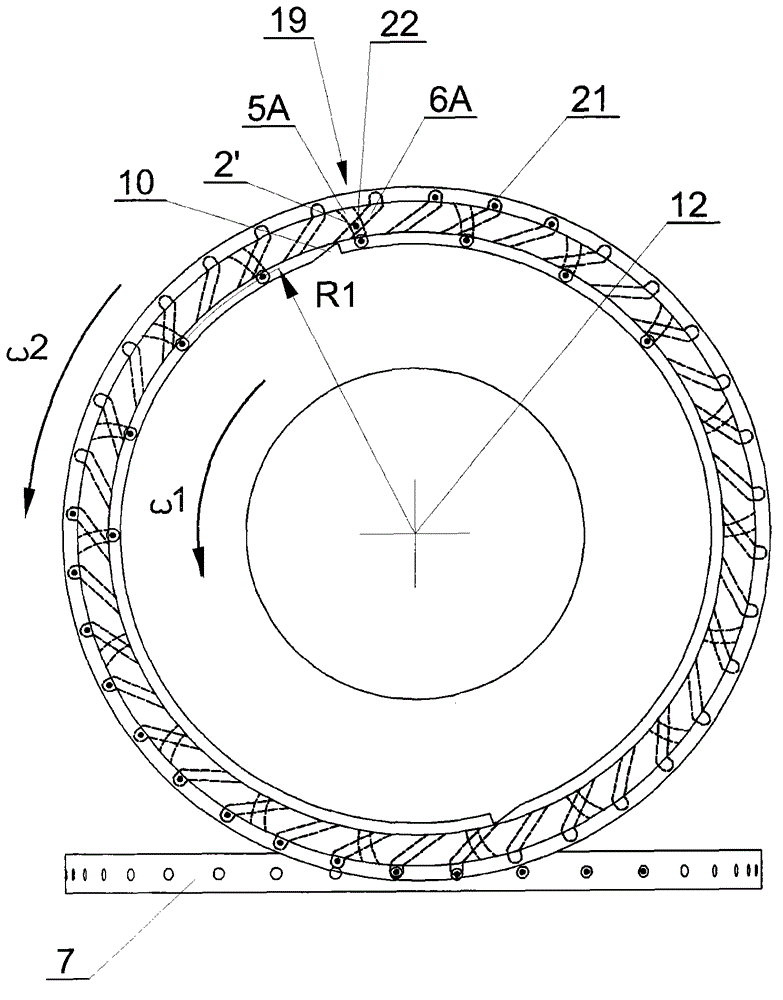

[0025] Figure 2a A plan view of a part of the bead feeder 1 is shown. The bead 2 supply unit 3 is provided with a plurality of fixed channels in the form of tubes 4 spaced apart on an arc with a radius R1, the tubes being supplied from the container 2A, but only shown in the tube One bead 2 above the entrance. The first holding well 14 ( image 3 ) Is located at the outlet of the tube 4, from the first holding trap the beads are transferred to the second receiving trap 18 ( Figure 4 ), the second receiving trap belongs to the unit 13 for transferring the beads 2 to the transfer wheel 7, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com