A kind of preparation method of high-purity trigonine

The technology of a tertenin and compound is applied in the field of preparation of high-purity terranine, which can solve the problems of expensive raw material dithiooxalic acid, low comprehensive yield, and few steps, and achieve good development prospects and low cost. The effect of low and three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

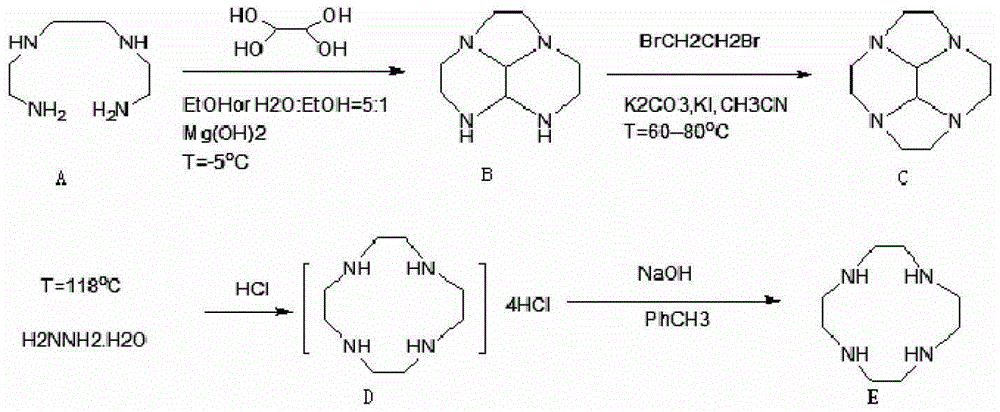

[0087] Embodiment 1: the preparation of trigonine

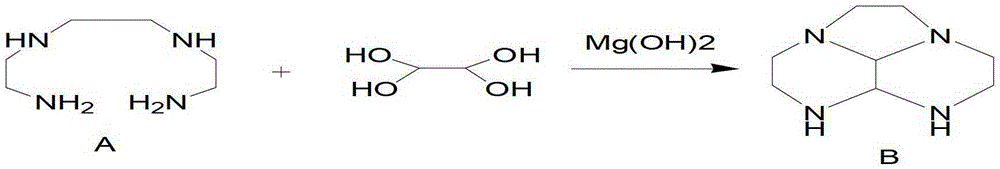

[0088] first step:

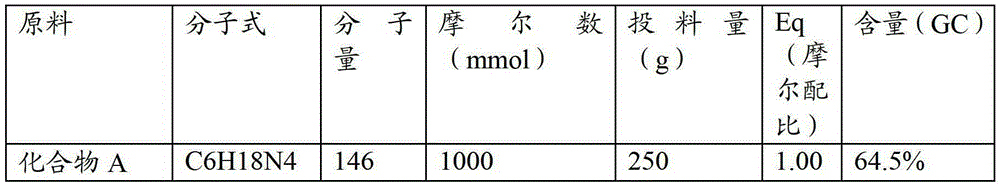

[0089] Add 195g (1.03mol) of TETA hydrate to a 2000ml four-necked bottle with a thermometer, add 750ml of drinking water and 150ml of ethanol, under stirring, add 110g (1.9eq) of magnesium hydroxide under nitrogen gas, and then cool to -5 degrees. Add dropwise glyoxal aqueous solution (145g 40% glyoxal, 400mL water and 100ml ethanol) (1.0eq), add dropwise for 2 hours, keep at -5°C for 2 hours after addition, filter with air (spread a layer of silicon bath soil) , the solid was washed once with a small amount of water, the filtrate and washings were combined, the filtrate was concentrated under reduced pressure with a rotary evaporator to obtain a dry residue, the residue was added to 150ml of toluene to separate water, and anhydrous potassium carbonate was added to dry to obtain a light yellow oil compound B .

[0090] Step two:

[0091] Add 152g (4.50eq) of anhydrous sodium carbonate, 21.6g (0.45eq) o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com