Beam string structure

A chord beam and surface structure technology, applied in building structures, buildings, etc., can solve the problems of the center of gravity shift of the chord beam structure, the failure of the chord beam, and the failure of the function, so as to prevent continuous collapse, improve the anti-collapse performance, and eliminate potential safety hazards. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

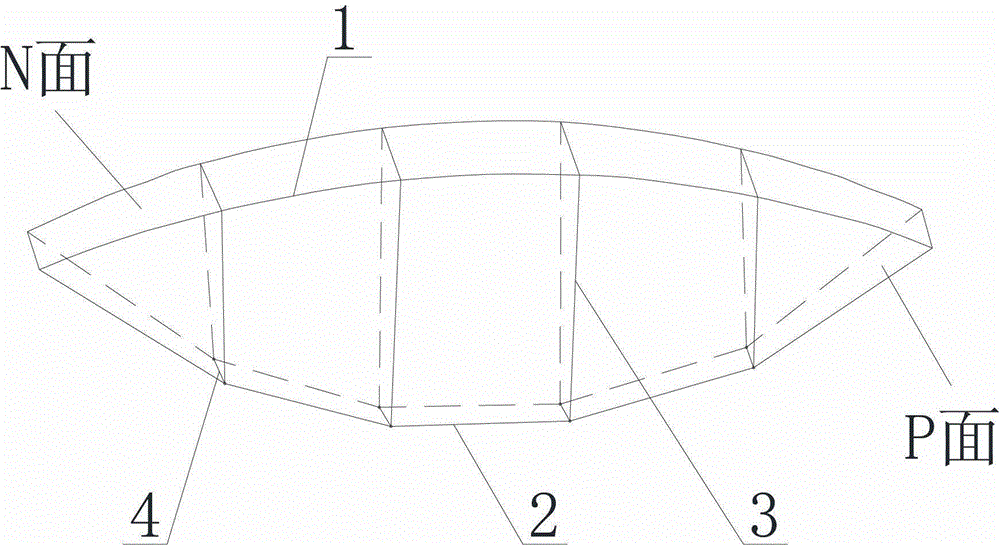

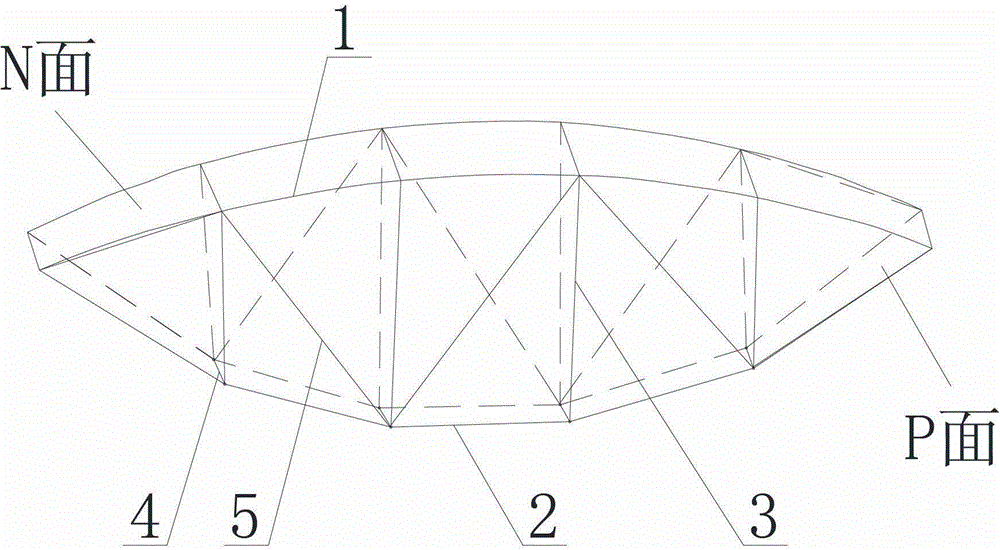

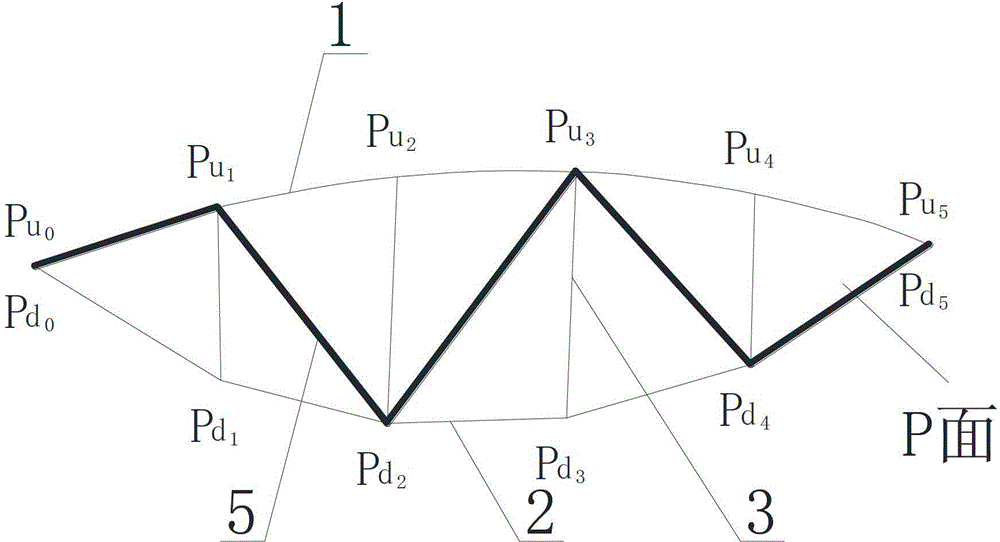

[0020] Such as figure 2 Shown is a schematic diagram of a string string structure based on the idea of the present invention, including a pair of upper string girders 1 (or arches or trusses), several pairs of struts 3 and a pair of lower string stay cables 2, the paired upper string girders 1, formed The pair of struts 3 and the pair of lower string stay cables 2 are symmetrically arranged on both sides of a symmetrical plane, and the upper run beam 1, strut bar 3 and lower string stay cables 2 on the same side of the symmetrical plane form a plane structure, record the surface structures on both sides of the symmetrical surface as P surface and N surface respectively; It is hinged with the upper chord beam 1, and the lower end of the strut 3 is fixedly connected with the lower chord cable 2; Fixed connection; several short stay cables 5 are respectively arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com