Combined wire binding device

A cable tie and combined technology, which is applied in the direction of building types, cable installation devices, electrical components, etc., can solve the problems of short service life and easy corrosion of the cable, and achieve the effect of convenient operation, convenient portability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

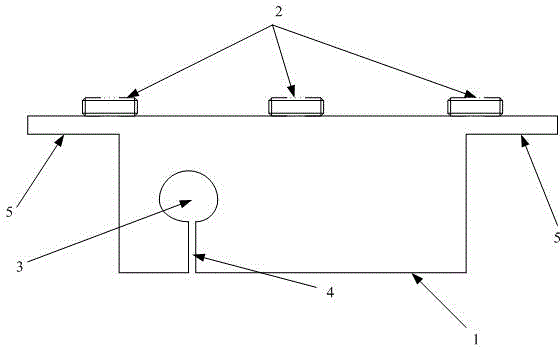

[0015] The combined wire binding device of the present invention includes an operating lever and a binding plate 1, a lead hole 3 is opened on the binding plate, and a lead groove 4 is opened from the lead hole 3 to the edge of the binding plate, and the binding plate An operating rod sleeve 2 is also fixed on the edge, and the inner diameter of the operating rod sleeve is greater than the outer diameter of the operating rod.

[0016] During use, the operating rod is passed through the operating rod sleeve 2, and the binding plate and the operating rod are fixed together by the operating rod sleeve. The lead wire is snapped into the lead wire hole of the wire tie plate from the lead wire slot, and after the wire tie is made, the end of the wire tie is sealed by the wire tie plate.

[0017] Using the combined wire tie device of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com