Integrated cooling system for fully mechanized mining faces

A fully mechanized mining face and cooling system technology, applied in cooling/ventilation devices, gear lubrication/cooling, electrical components, etc., can solve problems such as inability to use water recycling, waste of water resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

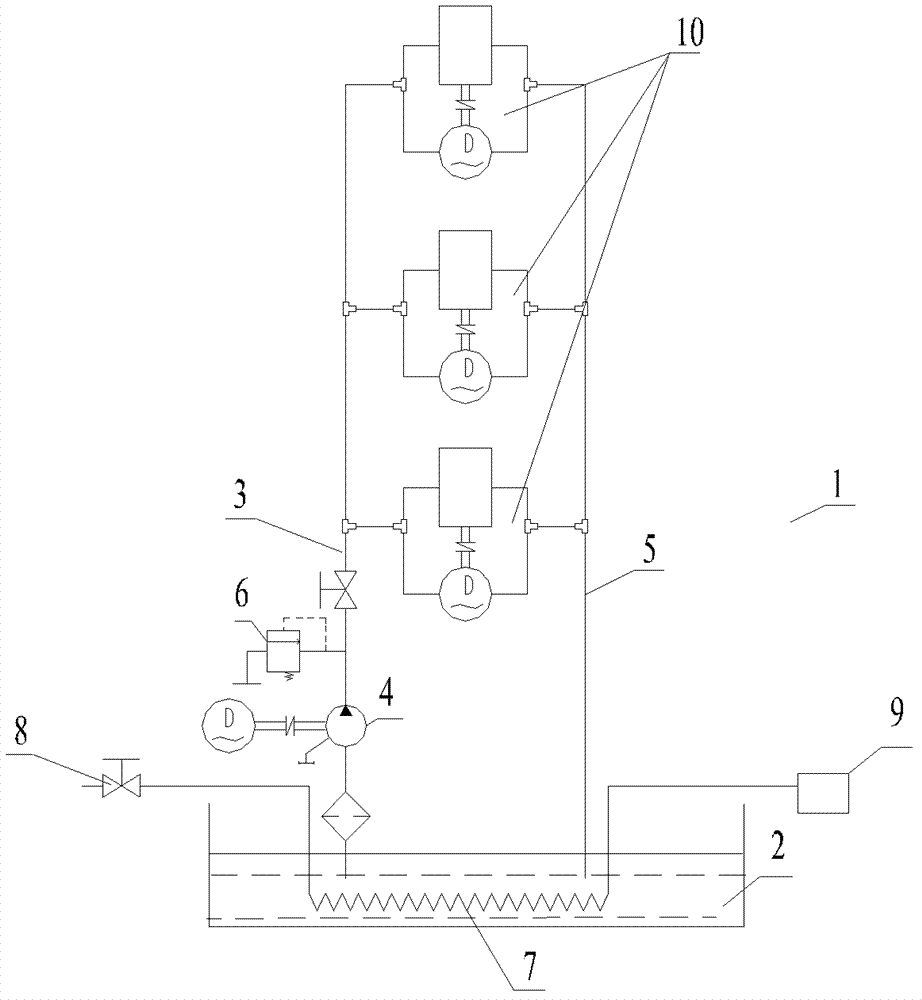

[0014] figure 1 It is a structural schematic diagram of the integrated cooling system of the fully mechanized mining face in the embodiment of the present invention, combined with figure 1 As shown, the embodiment of the present invention provides an integrated cooling system 1 for a fully mechanized mining face, including:

[0015] Coolant tank 2 for holding coolant, cooling pipeline 3, cooling pump 4, liquid return pipeline 5;

[0016] One end of the cooling pipeline 3 goes deep below the liquid level of the cooling liquid tank 2, the cooling pipeline 3 is connected with a cooling pump 4, and the other end of the cooling pipeline 3 is connected to the cooling liquid input end of each fully mechanized mining face equipment 10 to be cooled , the cooling pump 4 is used to extract the cooling liquid into the cooling pipeline 3 to provide cooling for each fully mechanized mining face equipment 10 to be cooled, and one end of the liquid return pipeline 5 is connected to each full...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com