Non-contact rotating vane vibration testing method based on positioning without rotating speed

A vibration test, non-contact technology, applied to measuring devices, measuring ultrasonic/sonic/infrasonic, instruments, etc., to simplify modification work, easy application, and eliminate unsafe factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

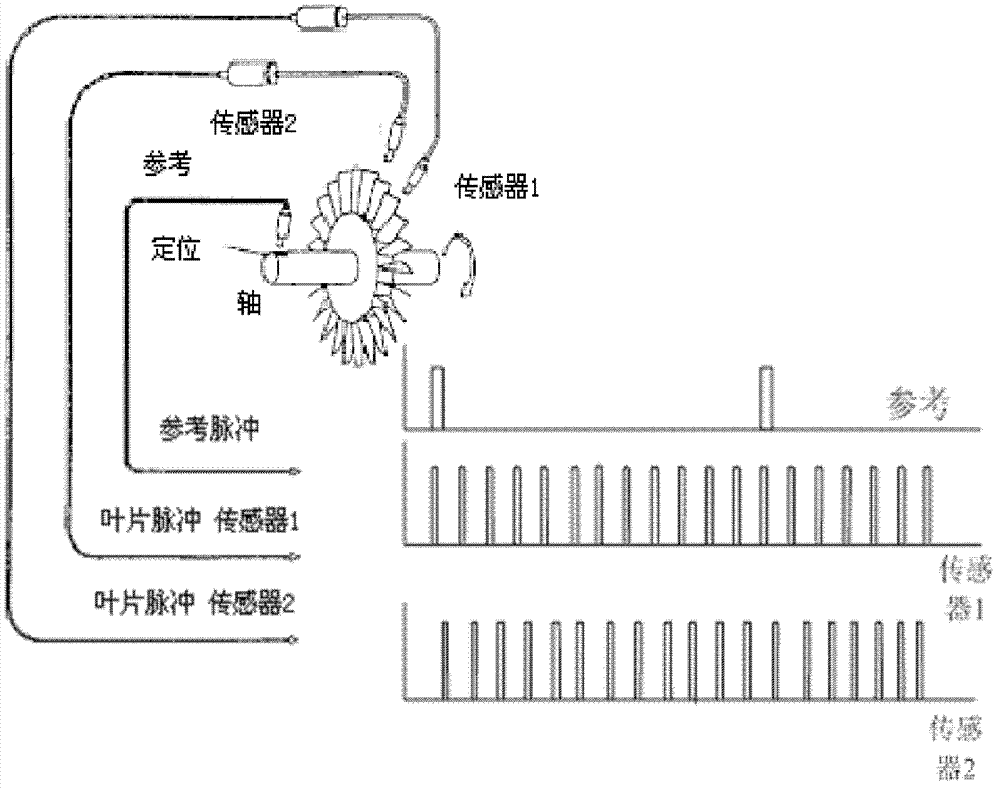

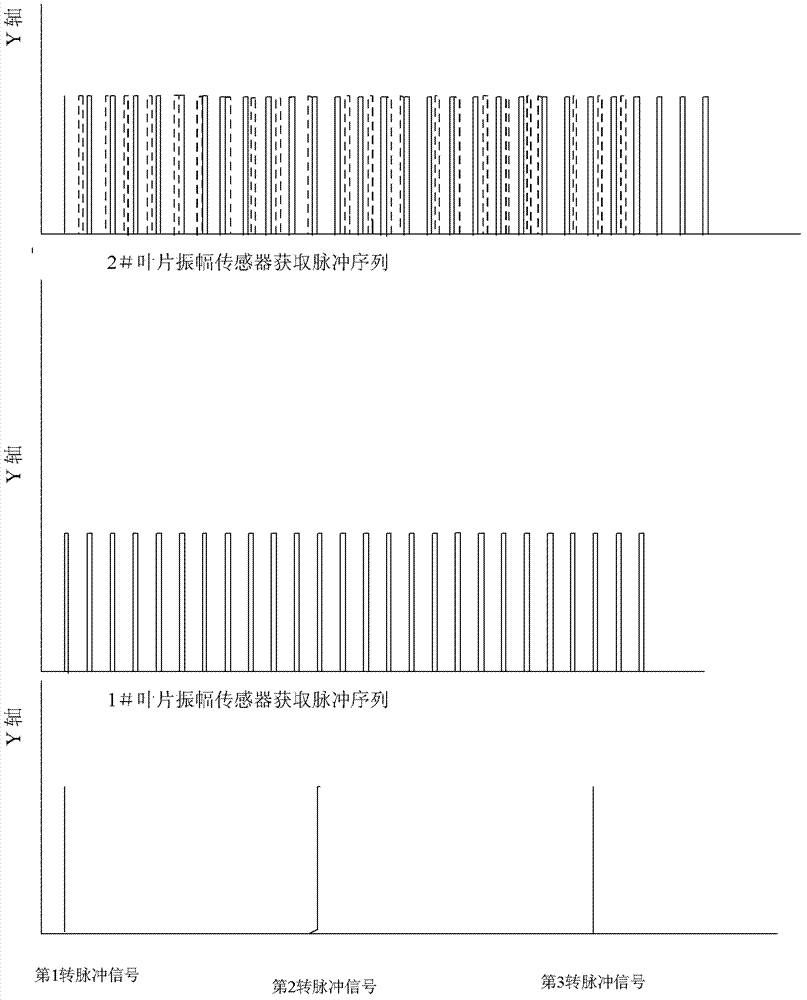

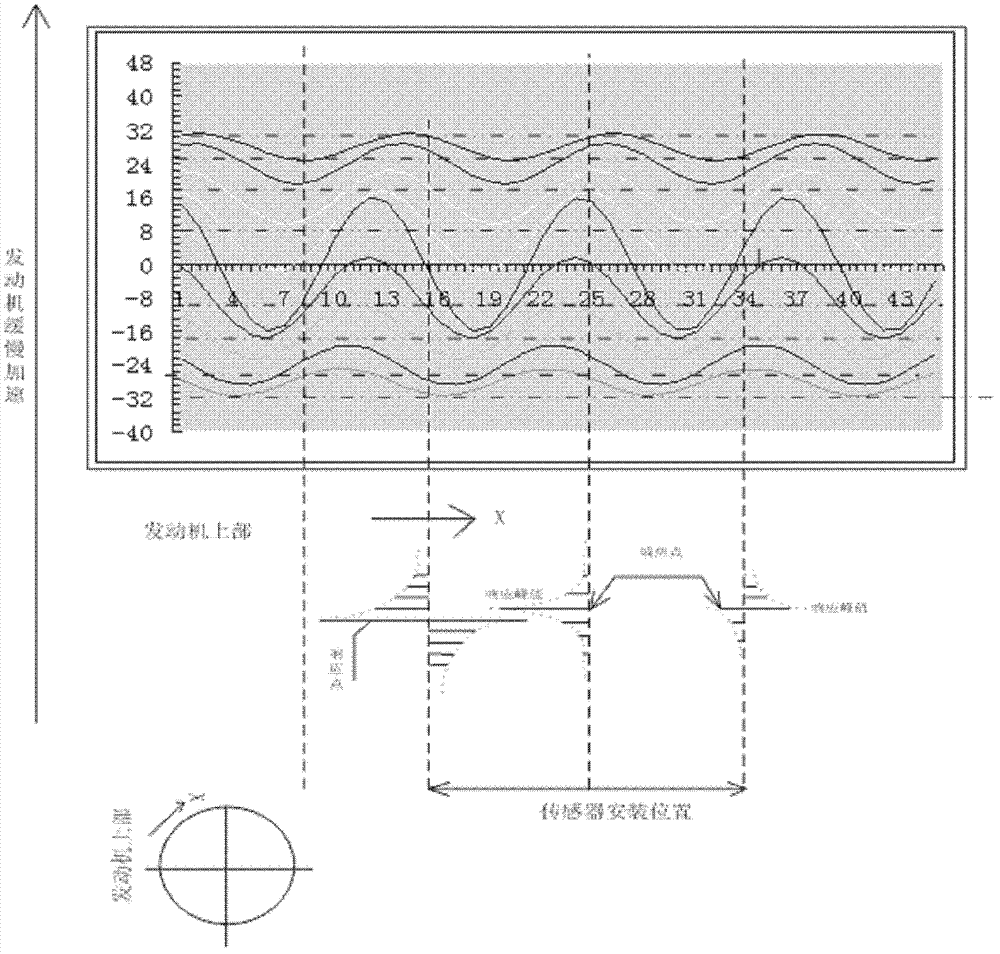

[0031] This embodiment provides a non-contact rotating blade vibration test method based on non-rotating speed positioning, which is characterized in that: the non-contact rotating blade vibration testing method based on non-rotating speed positioning is aimed at the commonly used non-contact rotating blade There are problems in the vibration test of rotating blades. An improved non-contact blade vibration test method based on blade pulse positioning. The principle of non-contact rotating blade vibration test is as follows figure 1 , Install a magnetic steel sensor on the rotor to obtain the positioning reference pulse signal, install two blade tip amplitude sensors above the measured blade casing, and another positioning reference sensor is installed on the shaft to give the blade speed and the blade When the blade vibrates, it passes through the time interval of the blade tip amplitude sensor; when the blade vibrates, the blade tip shifts in the direction of rotation, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com