Combined-type material clamp

A combined and material technology, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems of inability to clamp materials, poor universality of fixtures, and inability to adjust angles, etc., to achieve the effect of convenient operation, accurate response, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

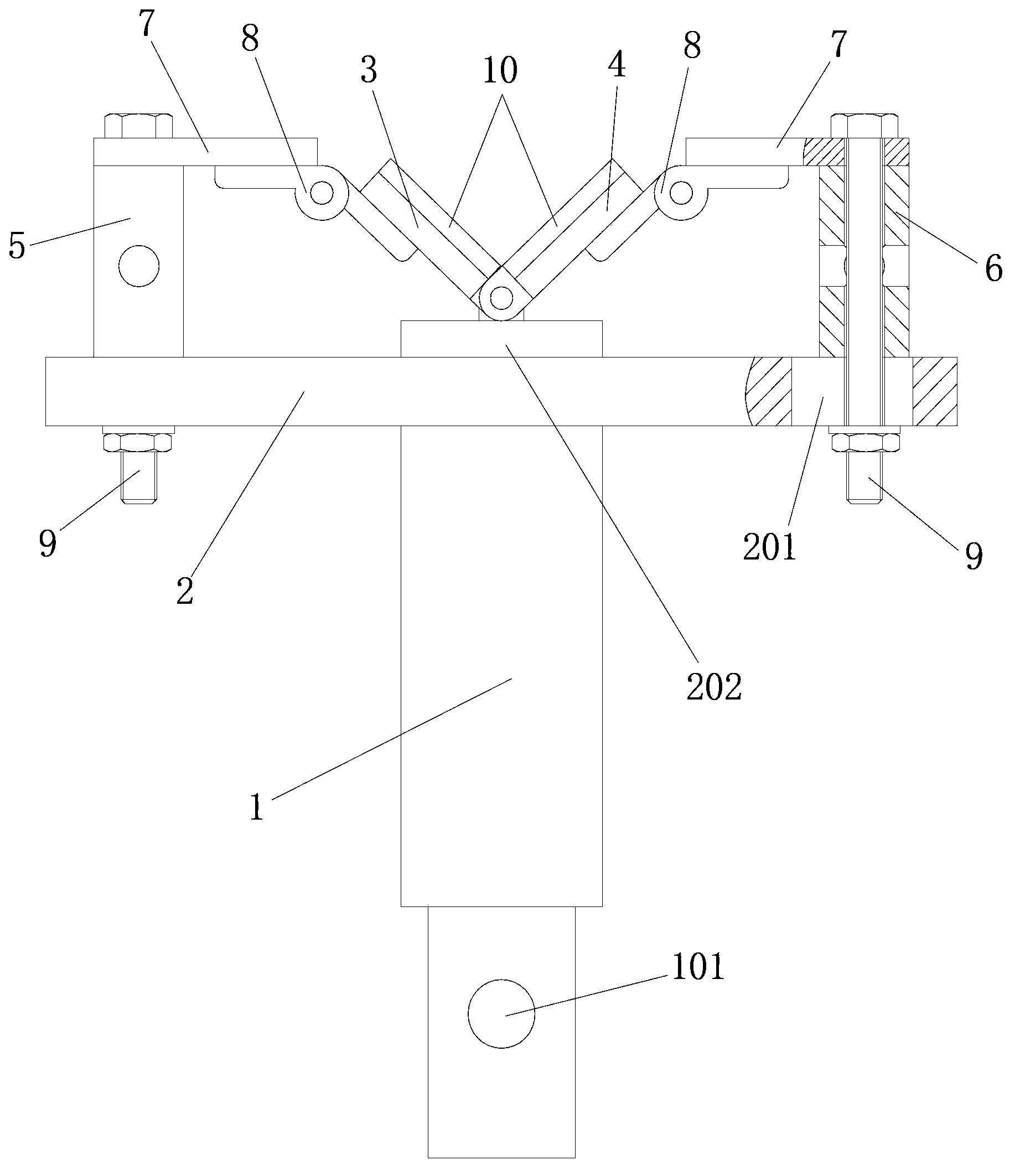

[0026] like figure 1 A combined material clamp is shown, the clamp device includes a connecting shaft 1, a supporting plate 2, a first clamping plate 3 and a second clamping plate 4, the supporting plate 2 is installed on one end of the connecting shaft 1, and the supporting plate The two ends of 2 are respectively provided with a first spacer 5 and a second spacer 6, one end of the first splint 3 is connected to the first spacer 5, and the other end is hinged to the middle part of the support plate 2; One end of the splint 4 is connected to the second spacer 6 , and the other end is hinged to the middle of the support plate 2 , while the other end of the first splint 3 is hinged to the other end of the second splint 4 . In order to facilitate the installation of the combined material fixture on the compression universal testing machine, the other end of the connecting shaft 1 is provided with a mounting hole 101 matched with the compression universal testing machine.

[0027...

Embodiment 2

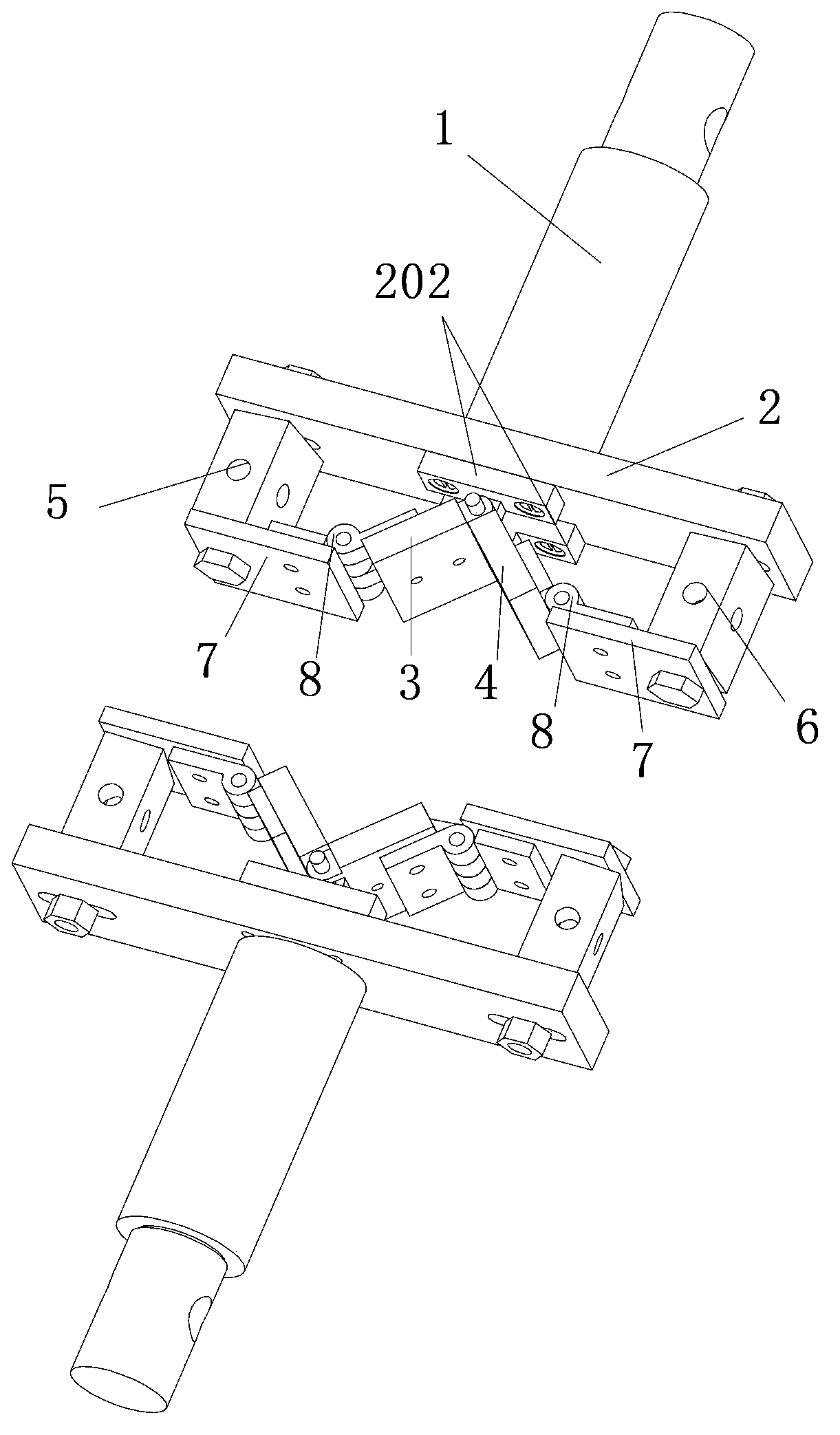

[0035] This combined material fixture is the same as embodiment 1 except the following technical features: as figure 2 As shown, the number of the combined material clamps is 2. When there are 2 combined material fixtures, the 2 combined material fixtures are respectively installed on the upper end and the lower end of the compression universal testing machine, and the lower end of the material to be tested is placed on the carrier 10 in the combined material fixture below. , and the upper end of the material to be tested is supported by the applicator 10 in the upper combined material clamp, so that through the cooperation of the two combined material clamps, the material to be tested is clamped.

Embodiment 3

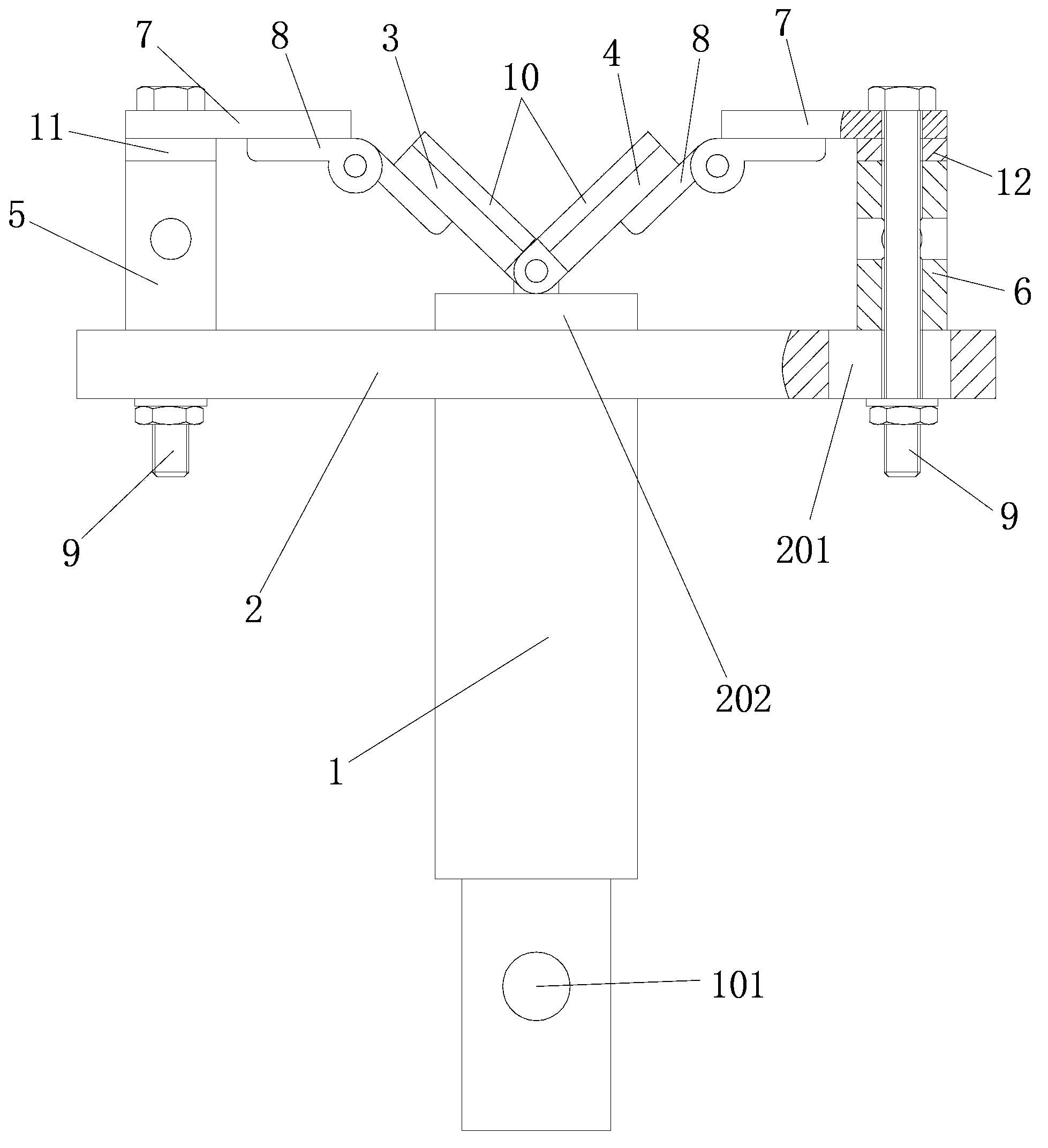

[0037] This combined material fixture is the same as embodiment 1 except the following technical features: as image 3 As shown, the combined material fixture also includes a first adjusting block 11 and a second adjusting block 12, the first adjusting block 11 is installed on the upper end of the first cushion block 3, and the second adjusting block 12 is installed on the upper end or the lower end of the second cushion block 4. The height adjustment is performed by increasing the number of the first adjusting block 11 and the second adjusting block 12 , which can realize quick adjustment of the angle between the first clamping plate 3 and the second clamping plate 4 . The middle parts of the first adjusting block 11 and the second adjusting block 12 are both provided with U-shaped slots. When loosening the bolts, without fully unscrewing the bolts 9, make the slot in the first adjusting block 11 face the bolts 9, and then insert the first adjusting block 11 into the connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com