Magnetic compatible tactile stimulator

A stimulator, magnetic compatibility technology, applied in medical science, using pressure for diagnosis, sensors, etc., can solve problems such as inability to achieve tactile spatial resolution, complex stimulator design, and air pressure instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

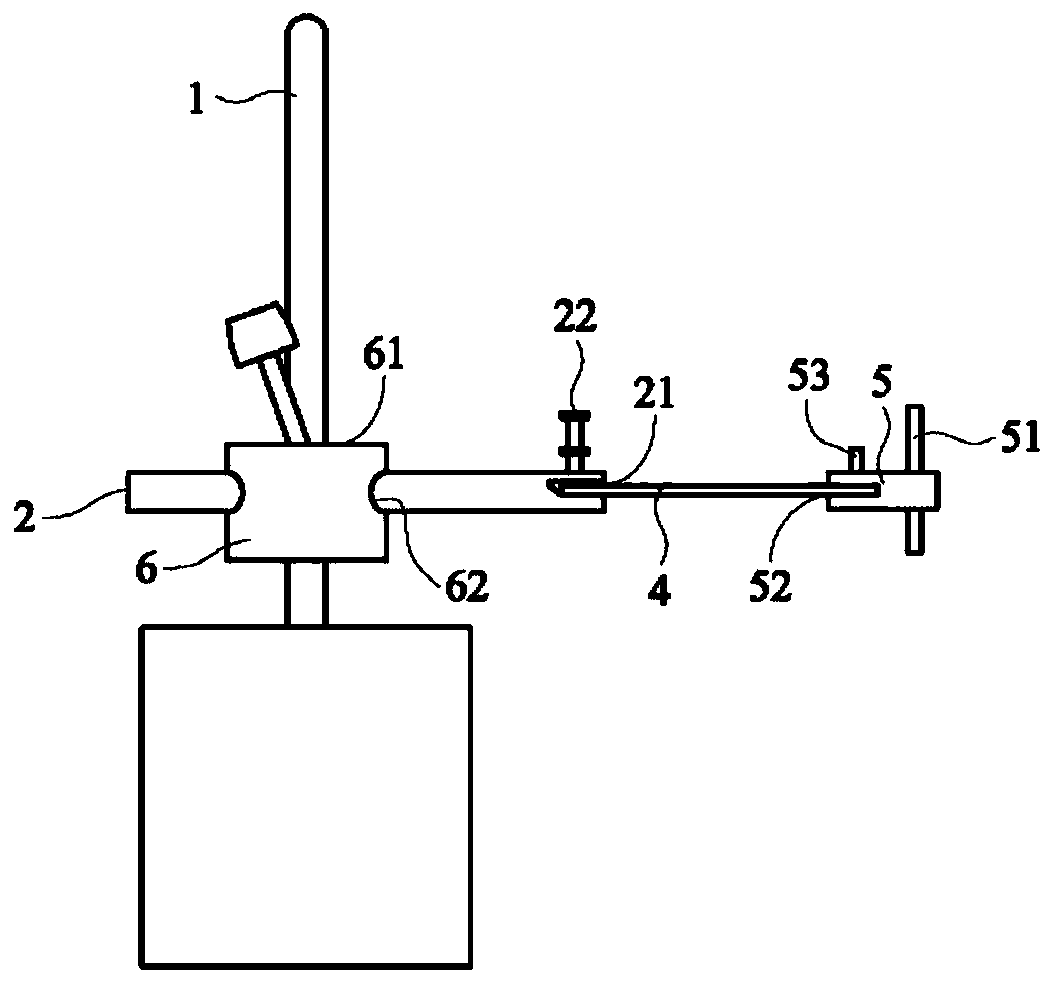

[0035] The magnetically compatible tactile stimulator provided in this embodiment includes:

[0036] The column 1 is vertically connected with the extension arm 2 through the connecting block 6;

[0037] The extension arm 2 is vertically connected with the column 1 through the connecting block 6, and moves up and down or rotates axially relative to the column 1;

[0038] Ceramic piezoelectric sheet 4, one end is connected with extension arm 2, the other end is connected with stimulating element 5, and realizes vibrations of different intensities and frequencies under the control of the control unit;

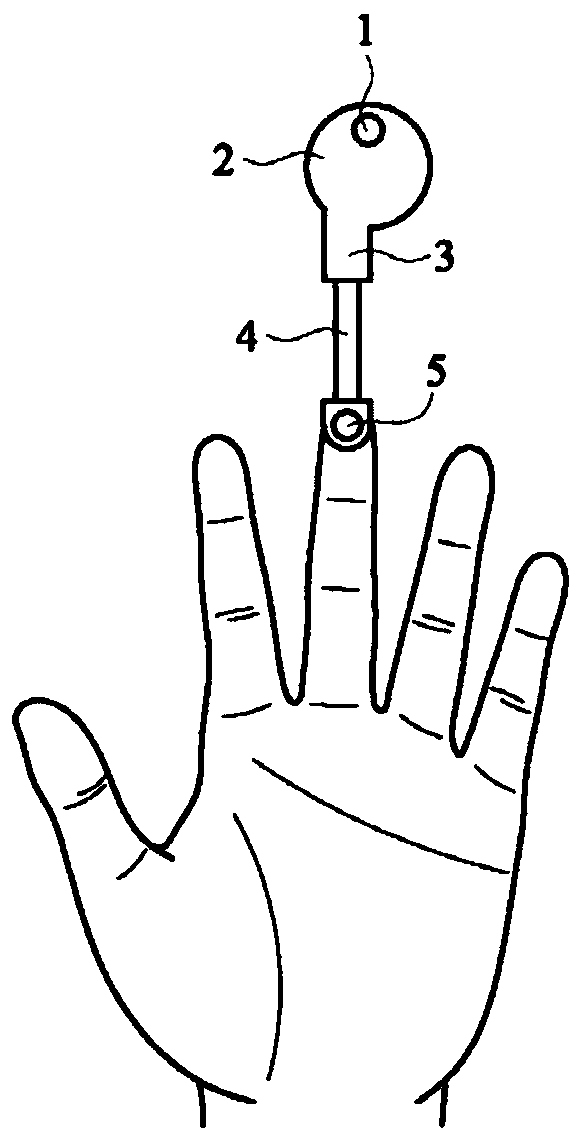

[0039] The stimulus 5 is connected to the other end of the ceramic piezoelectric sheet 4, and swings up and down with the vibration of the ceramic piezoelectric sheet 4 to provide tactile stimulation to the subject;

[0040] The control unit is electrically connected to the ceramic piezoelectric sheet 4 and controls the vibration intensity and frequency of the ceramic piezoelect...

Embodiment 2

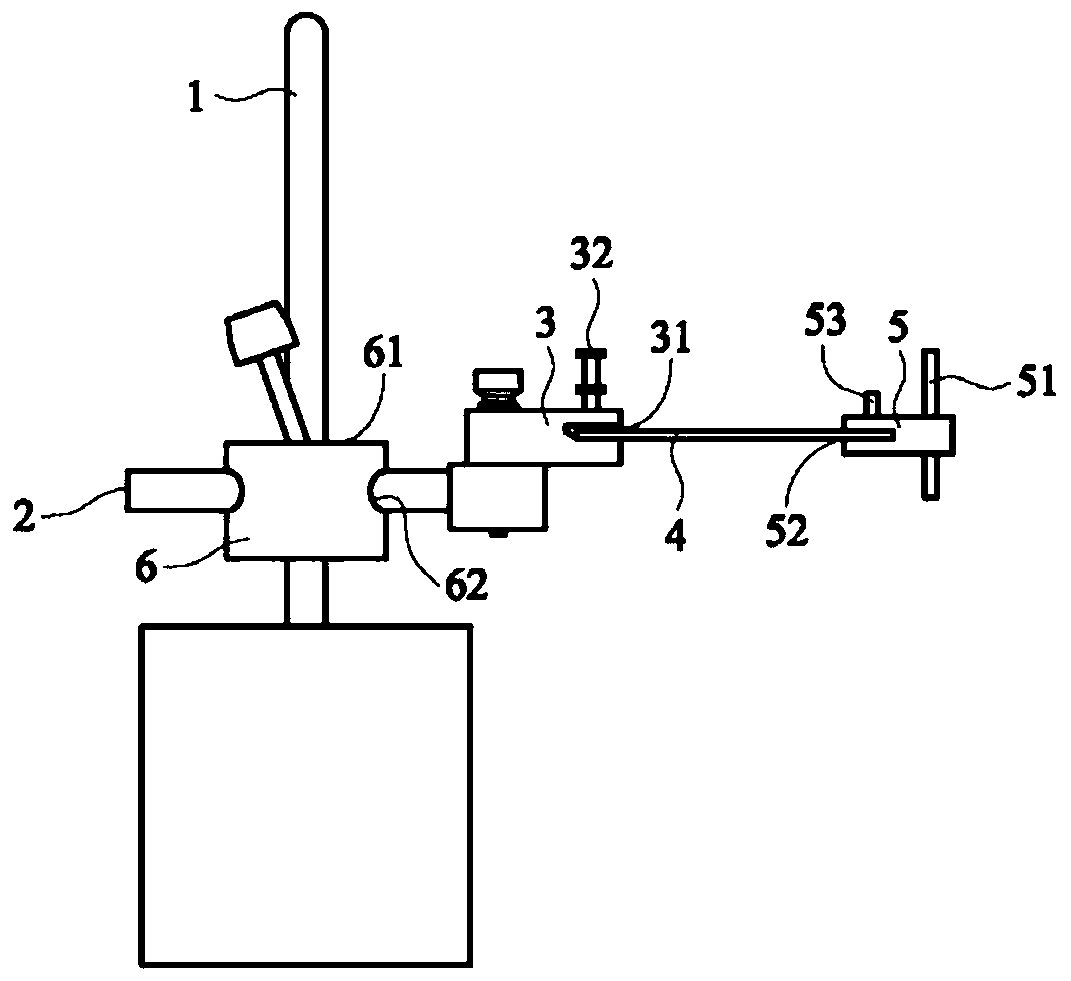

[0045] The magnetically compatible tactile stimulator provided in this embodiment includes:

[0046] The column 1 is vertically connected with the extension arm 2 through the connecting block 6;

[0047] The extension arm 2 is vertically connected with the column 1 through the connecting block 6, and moves up and down or rotates axially relative to the column 1;

[0048] Ceramic piezoelectric sheet 4, one end is connected with extension arm 2, the other end is connected with stimulating element 5, and realizes vibrations of different intensities and frequencies under the control of the control unit;

[0049] The stimulus 5 is connected to the other end of the ceramic piezoelectric sheet 4, and swings up and down with the vibration of the ceramic piezoelectric sheet 4 to provide tactile stimulation to the subject;

[0050] The control unit is electrically connected to the ceramic piezoelectric sheet 4 and controls the vibration intensity and frequency of the ceramic piezoelect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com