Miniature piezoelectric acceleration sensor

A piezoelectric acceleration and sensor technology, applied in the field of sensors, can solve the problems of complex internal structure, large mass and large volume, and achieve the effects of convenient operation, low production cost and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

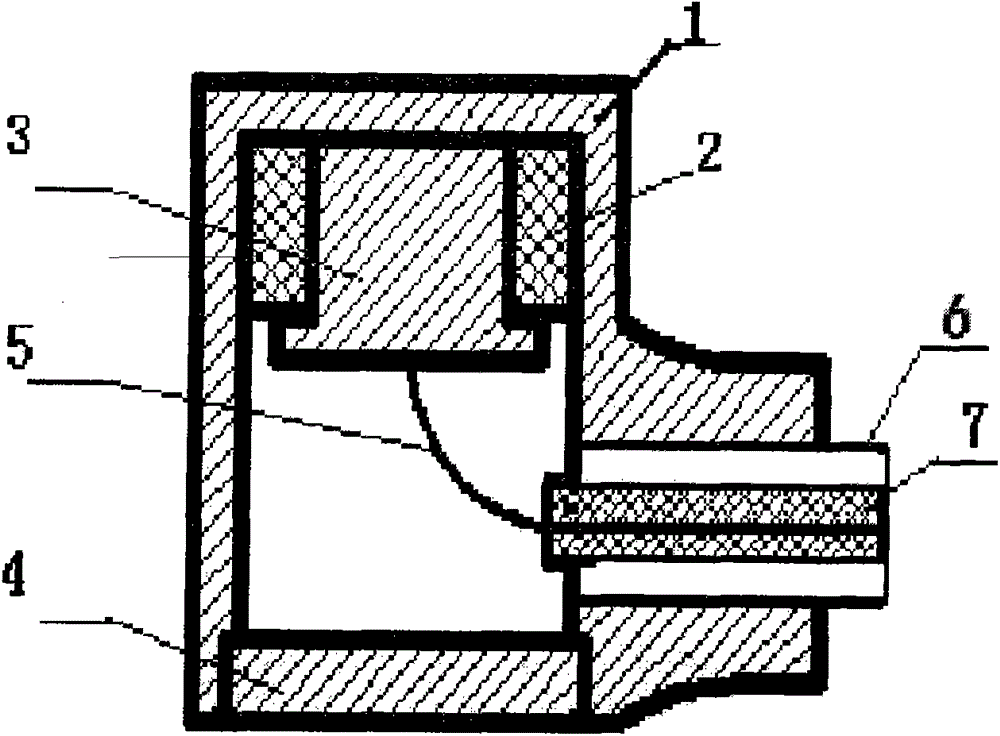

[0011] Such as figure 1 As shown, the design consists of a metal antimagnetic stainless steel shell 1, a piezoelectric annular shear piece 2, a conductive plate 3, a bottom cover 4, an output line 5, an insulating sleeve 1 6 and an insulating sleeve 2 7. The metal antimagnetic stainless steel housing 1 is the negative pole of a miniature piezoelectric acceleration sensor; the bottom cover 4 seals the metal antimagnetic stainless steel housing 1; The disk 3 is connected, the piezoelectric annular shear piece 2, and the conductive disk 3 are connected to the metal antimagnetic stainless steel shell 1, and the output line 5 is connected to the metal antimagnetic stainless steel shell 1. Insulation sleeve 2 7 and insulation sleeve 1 6 are arranged. The output line 5 is insulated from the metal antimagnetic stainless steel shell 1, and outputs the generated signal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com