Manufacturing method of light emitting diode packaging structure

A technology for light-emitting diodes and packaging structures, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of uneven distribution of phosphors, affecting the light-emitting effect of light-emitting diode packaging structures, etc., and achieve the effects of uniform distribution and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

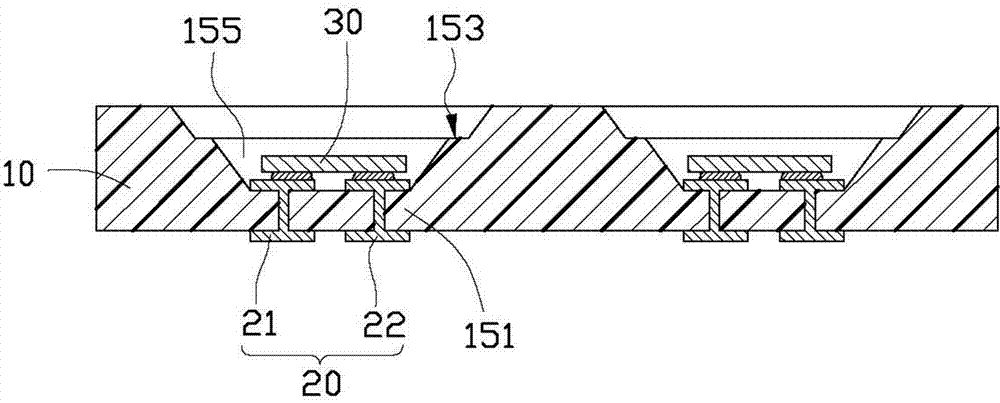

[0018] Such as Figure 7 As shown, the light emitting diode packaging structure 100 provided by the embodiment of the present invention includes a substrate 10, a circuit structure 20 formed on the substrate 10, a light emitting diode chip 30 carried on the substrate 10 and electrically connected to the circuit structure 20, and the packaging structure The fluorescent encapsulation layer 40 of the LED chip 30 .

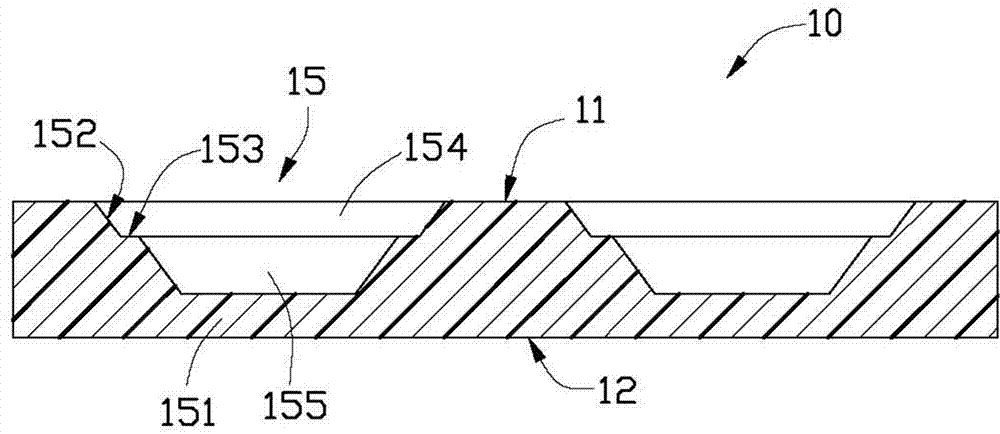

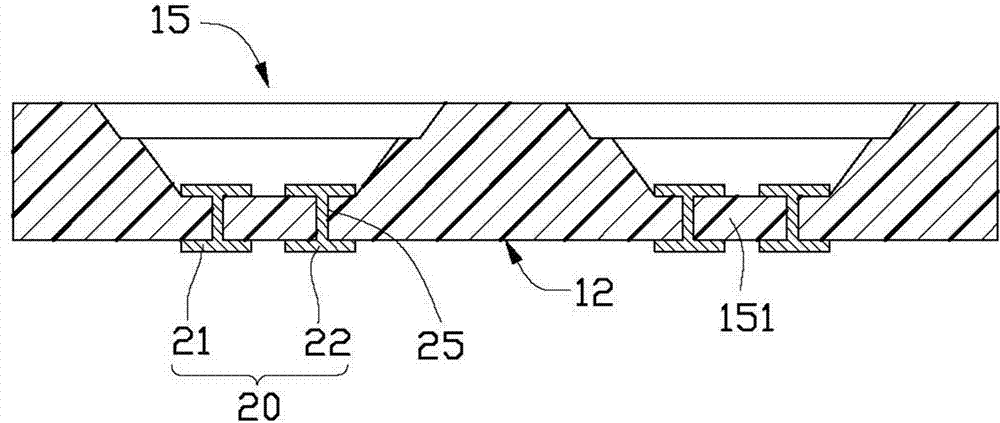

[0019] In this embodiment, a groove 15 is formed on the substrate 10 , the bottom of the groove 15 is a bottom plate 151 and the surrounding is a side wall 152 . The circuit structure 20 is disposed on the base plate 151 . The light emitting diode chip 30 is accommodated in the groove 15 , and is fixed and electrically connected to the circuit structure 20 of the substrate 10 in a flip-chip manner. The LED chip 30 includes a light emitting surface 31 opposite to the substrate 10 , and two electrodes 32 are disposed on the other surface opposite to the light emitting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com